5-64 4203780 First Edition

HYDROSTATIC POWER TRAIN

5

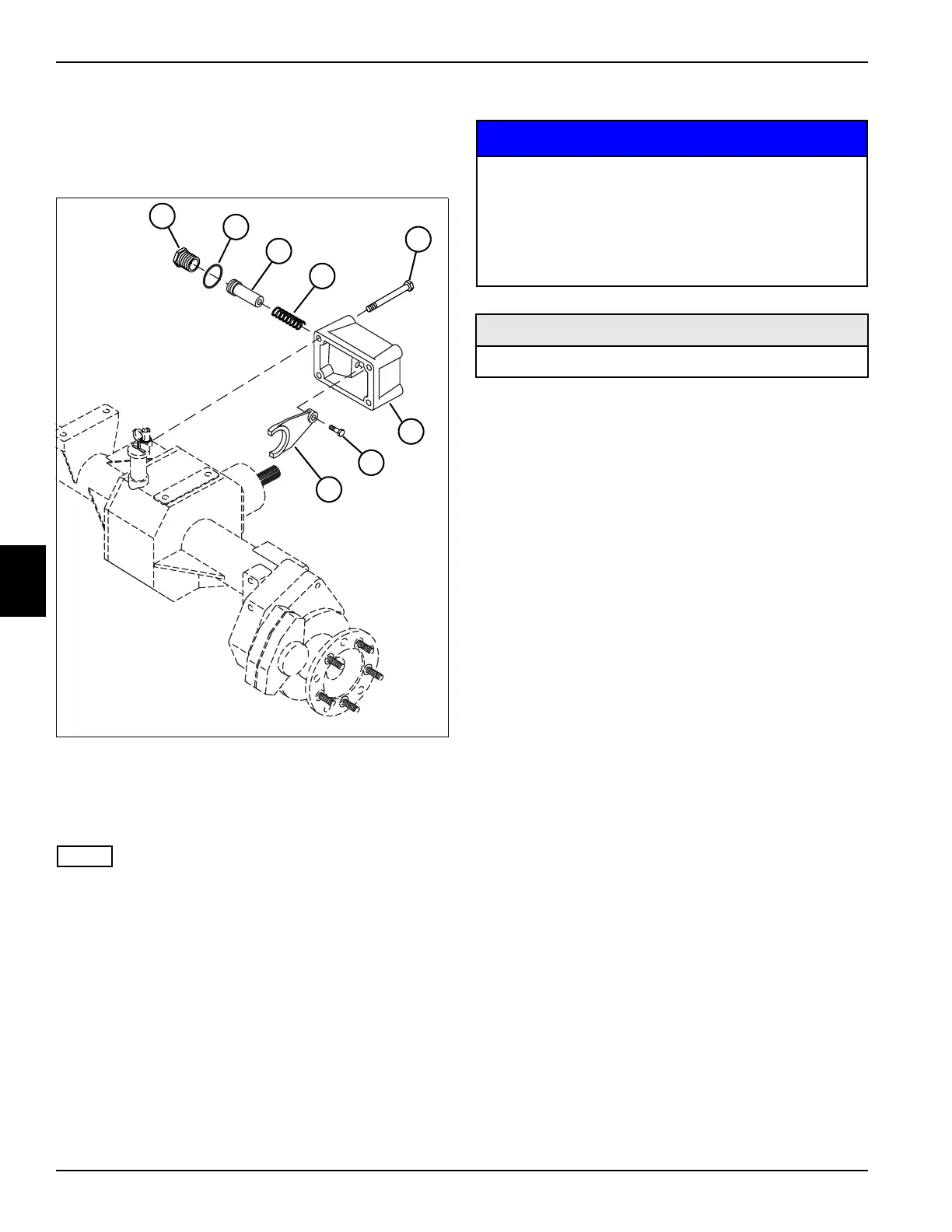

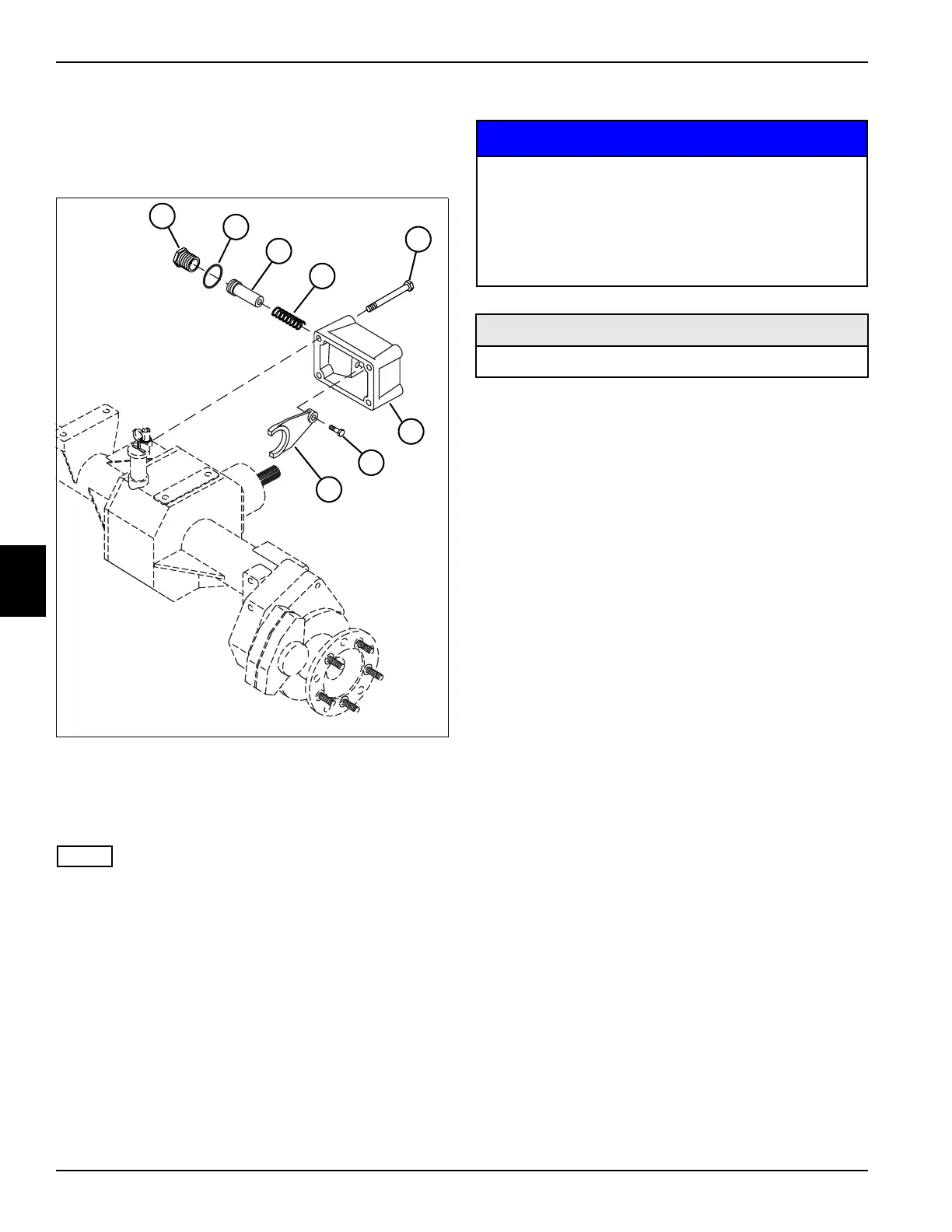

Differential Lock Assembly

Disassembly, Inspection, and Assembly

See Figure 5-68.

Figure 5-68

NOTE

If it is necessary to replace the differential lock collar, see

“Differential Assembly” on page 5-73.

1. Disassemble differential lock assembly as shown.

2. Place parts in assembly order on a clean work area

as they are removed.

Inspection Notes

• Keeping parts in assembly order, clean and air dry

each item for inspection.

• Inspect for worn or defective parts.

• Inspect all parts for cracks, nicks, burrs, and

excessive wear. Inspect for scoring, galling, and

scratches on surfaces. Replace parts as necessary.

Assembly Notes

NOTICE

• Assemble the differential lock assembly by reversing

the order of disassembly.

• Lubricate all O-rings prior to assembly.

• Apply Loctite 242 (Blue) to fork screw (7) before

assembly, and tighten to 19 lb-ft (26 N·m).

• Apply Loctite 242 (Blue) to housing screws (5) before

assembly, and tighten to 37 lb-ft (51 N·m).

1Cylinder 5Screw (4)

2 O-Ring 6 Housing

3Piston 7Screw

4Spring 8Fork

TN1907

2

6

7

8

3

4

5

1

• It is important that all parts are absolutely

clean, as contamination can result in serious

damage and/or improper operation.

• Never use shop towels or rags to dry parts

after cleaning, as lint may clog passages. Dry

parts using compressed air.

Required Materials

Loctite

®

242 (Blue)

Loading...

Loading...