5-60 4203780 First Edition

HYDROSTATIC POWER TRAIN

5

Inspection Notes

• Keeping parts in assembly order, clean and air dry

each item for inspection.

• Inspect for worn or defective parts.

NOTE

Do not lap the piston shoes, piston block, or backplate

surfaces.

• Inspect pistons and shoes. The pistons should be

snug, and the shoes should be flat and display no

signs of flaking.

• Inspect piston block. Make sure the flat surface is

free of score marks.

• Inspect the flat surface of the backplate. It should be

free of score marks and metal build-up.

• Look for metal chips or slivers during cleaning (an

indication of damage to pump or other hydraulic

component).

• Inspect all parts for cracks, nicks, burrs, and

excessive wear. Inspect for scoring, galling, and

scratches on surfaces. Replace parts as necessary.

Assembly Notes

NOTICE

• Assemble the front wheel motor by reversing the

order of disassembly.

• Lubricate all O-rings prior to assembly.

• Press shaft seal (2) into the housing until the seal is

approximately 7/32 inch (5.5 mm) below the surface

of the housing.

• Install cam plate insert (9), making sure the lettering

is facing toward the housing (8).

• Tighten backplate assembly screws (13) 15—18 lb-ft

(20—24 N·m).

• Pressure filter traction system upon start-up if metal

debris is found in system oil or motor. (See “Portable

In-Line Filter” on page 5-4.)

Front (Drive) Axle Assembly

Removal and Installation

See Figures 5-57 through 5-67.

1. Park the mower safely. (See “Park Mower Safely” on

page 1-6.)

2. Remove the front mower deck. (See “Front Deck” on

page 8-19.)

3. Remove floorboard. (See “Floorboard” on

page 9-16.)

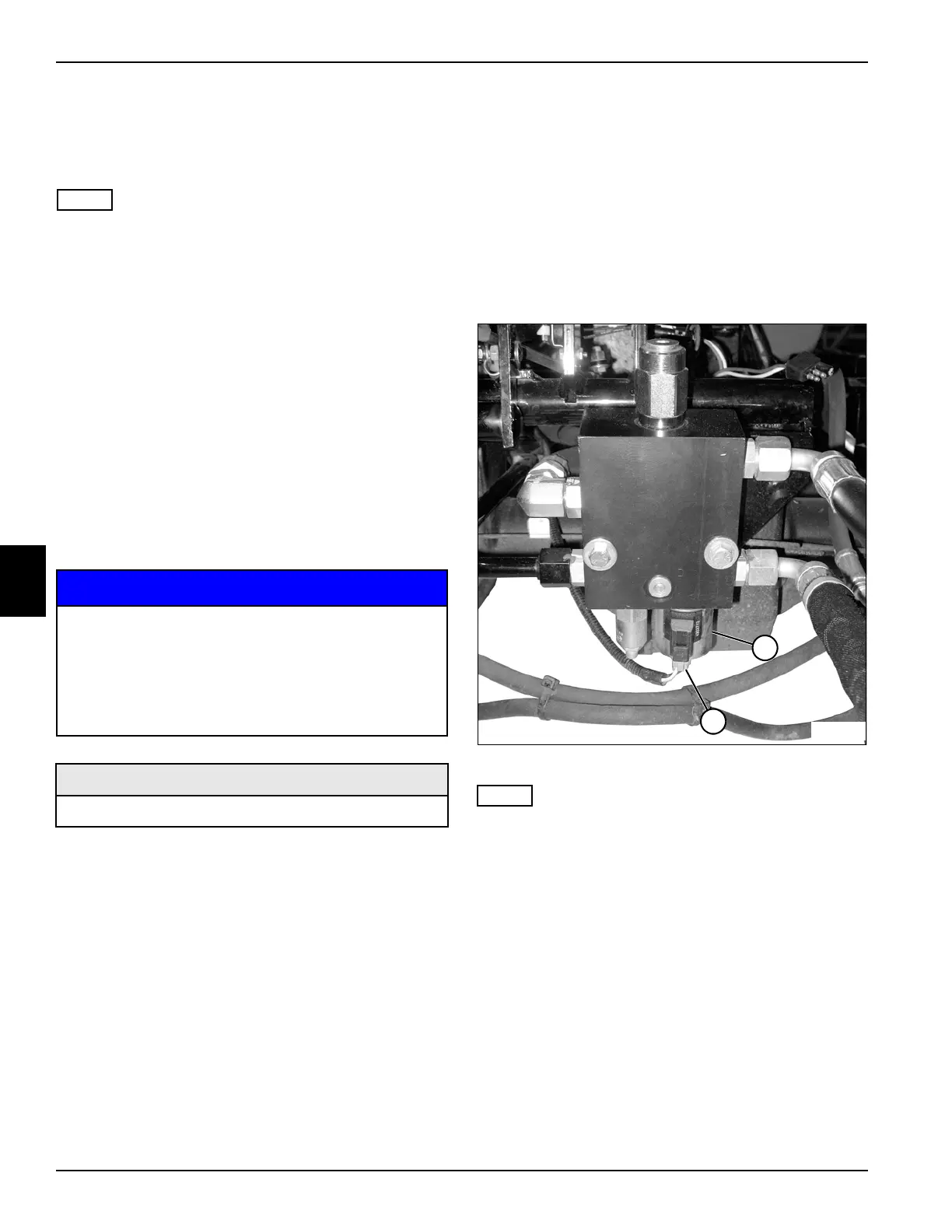

Figure 5-57

NOTE

Label all connectors before disconnecting to ensure

correct installation.

4. Disconnect wire harness connector (2) from the front

mower deck valve solenoid (1).

• It is important that all motor parts are

absolutely clean, as contamination can result

in serious damage and/or improper operation.

• Never use shop towels or rags to dry parts

after cleaning, as lint may clog passages. Dry

parts using compressed air.

Required Materials

Seal Kit (Jacobsen PN 557432)

TN2045

2

1

Loading...

Loading...