Workman HDX Auto Page 4 − 57 Drive Train

8. Carefully lower shift drum (Fig. 55 item 29) into trans-

mission while engaging the drum slots to the shift fork

pins (Fig. 67).

9. Make sure that mating surfaces of front and rear gear

case are clean. Apply silicone sealant to mating surface

of front gear case.

10.Install two (2) dowel pins (Fig. 55 item 10) into gear

case locations.

11.Carefully install rear gear case taking care to not

damage seal in gear case.

12.Secure transmission gear cases with flange head

screws. Tighten screws in three (3) steps in a crossing

pattern from 15 to 20 ft−lb (21 to 27 N−m). Make sure

that there is no shaft binding after assembly.

13. Apply a light coating of multi−purpose lithium grease

onto new O−ring (Fig. 55 item 60) for shift drum shaft. In-

stall lubricated O−ring into shaft groove.

14.Install shift components into rear gear case:

A. Noting location of missing tooth, slide sector gear

(Fig. 55 item 32) onto shift drum shaft. If necessary,

rotate shift drum so that the sector gear identification

mark is toward the location of the shift shaft (Fig. 55

item 43).

B. Noting location of missing tooth, slide sector gear

(Fig. 55 item 30) onto lower end of shift shaft. Lower

shaft with gear into rear case and align the identifica-

tion marks on the two (2) sector gears (Fig. 68).

C. Slide spacer and then detent star (Fig. 55 item 52

and 31) onto shift drum shaft. The detent star has a

missing tooth for alignment purposes.

D. Slide detent pawl (Fig. 55 item 33) onto shift shaft

making sure that recess on pawl face fully engages

the shift shaft shoulder.

E. Install compression spring (Fig. 55 item 22) into

case recess and onto the detent pawl pin.

F. Apply a light coating of multi−purpose lithium

grease onto new O−ring (Fig. 55item 51) for shift

shaft. Install lubricated O−ring into shaft groove

(Fig. 69).

15.Make sure that mating surfaces of rear gear case and

sector gear cover (Fig. 55 item 28) are clean. Apply sili-

cone sealant to mating surface of rear gear case.

16.Install sector gear cover and secure with flange head

screws. Tighten screws in two (2) steps in a crossing pat-

tern and to a final torque of 9 to 12 ft−lb (12 to 16 N−m).

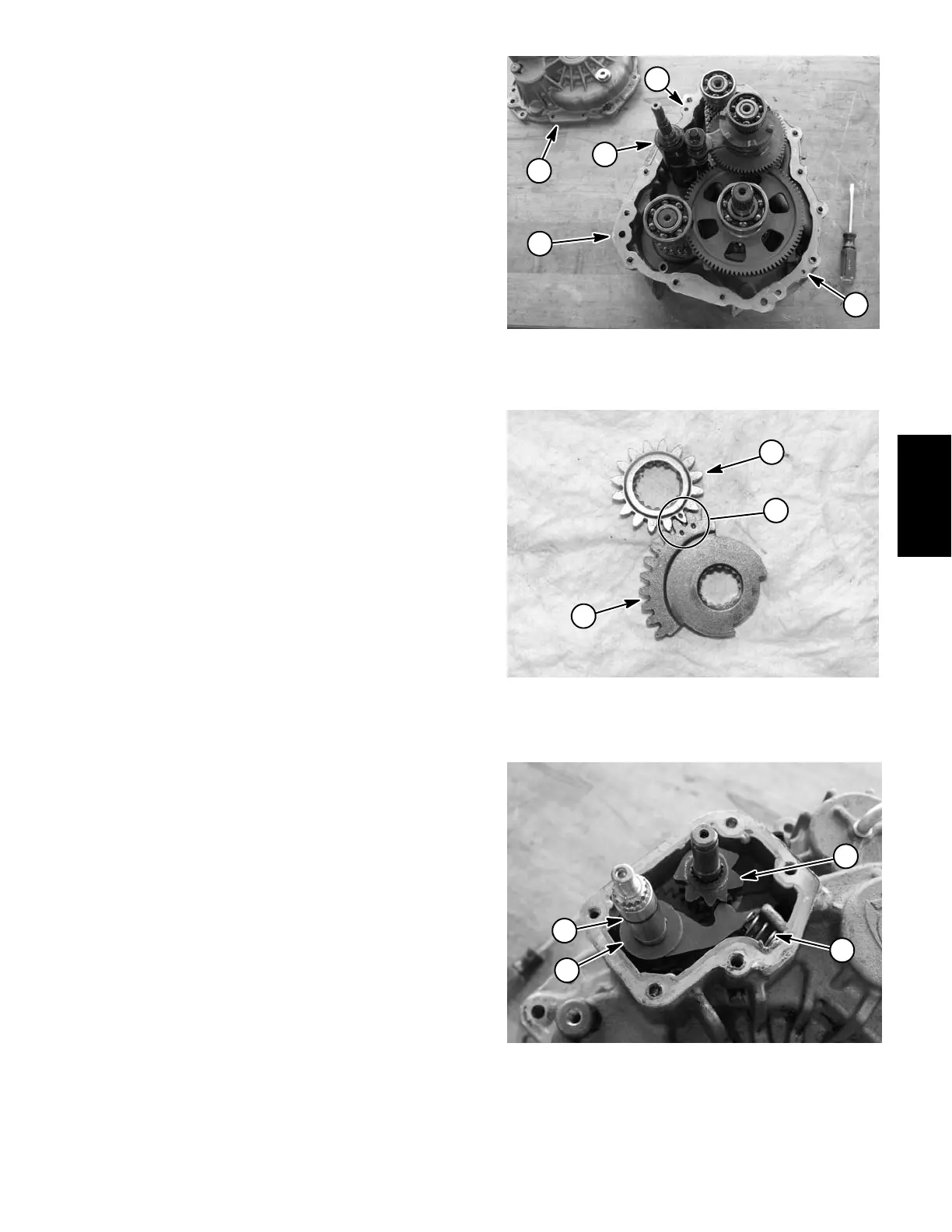

1. Rear gear case

2. Front gear case

3. Dowel pin location (2)

4. Shift drum

Figure 67

2

1

3

3

4

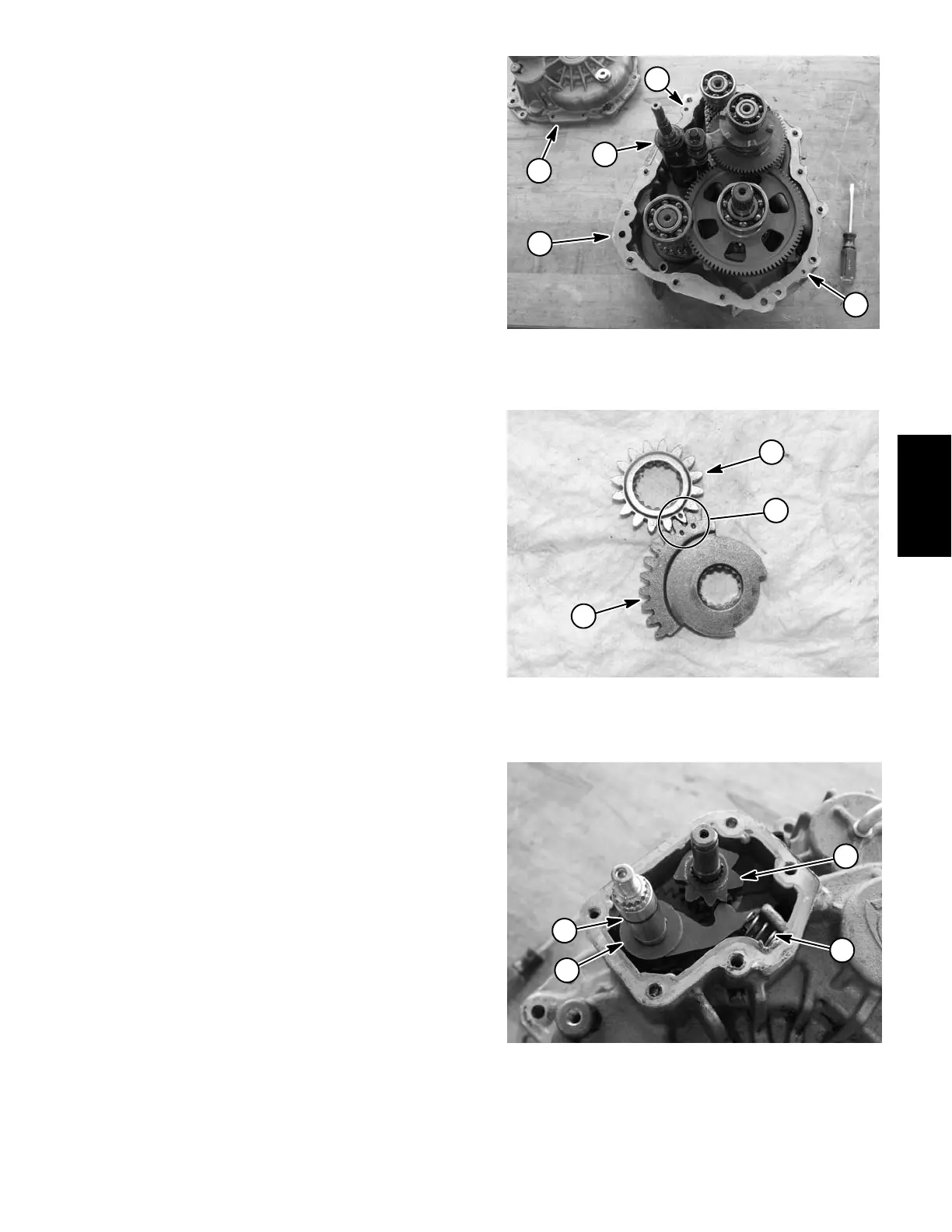

1. Shift drum sector gear

2. Shift shaft sector gear

3. Alignment marks

Figure 68

2

1

3

Figure 69

1. Compression spring

2. Detent pawl

3. Detent star

4. O−ring

1

1

3

4

SafetyProduct Records

Drive Train

Loading...

Loading...