Modbus TCP gateway

Wieland Electric GmbH | BA000970 | 11/2016 (Rev. F)

The following two settings can be simultaneously acti-

vated.

They determine the frequency of data transmission.

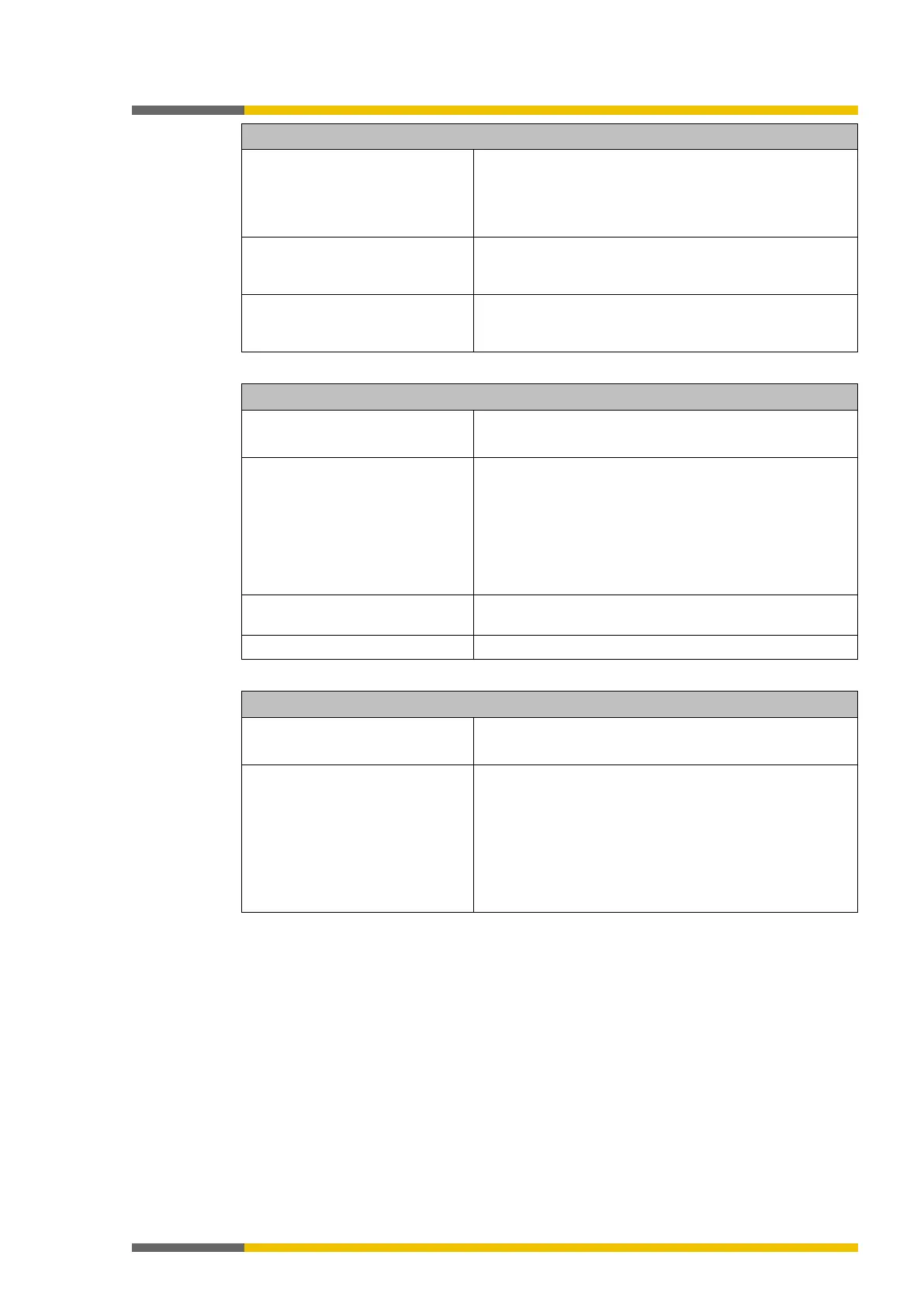

Activating the COS update

Determines that the SP-COP2-ENI module immediately

updates the data in the PLC as soon as changes are made

Activating the heart beat inter-

val

Use the heartbeat intervals which you defined in the

column to activate the update of the

Table 22: Settings for network -> samosPRO COMPACT direction

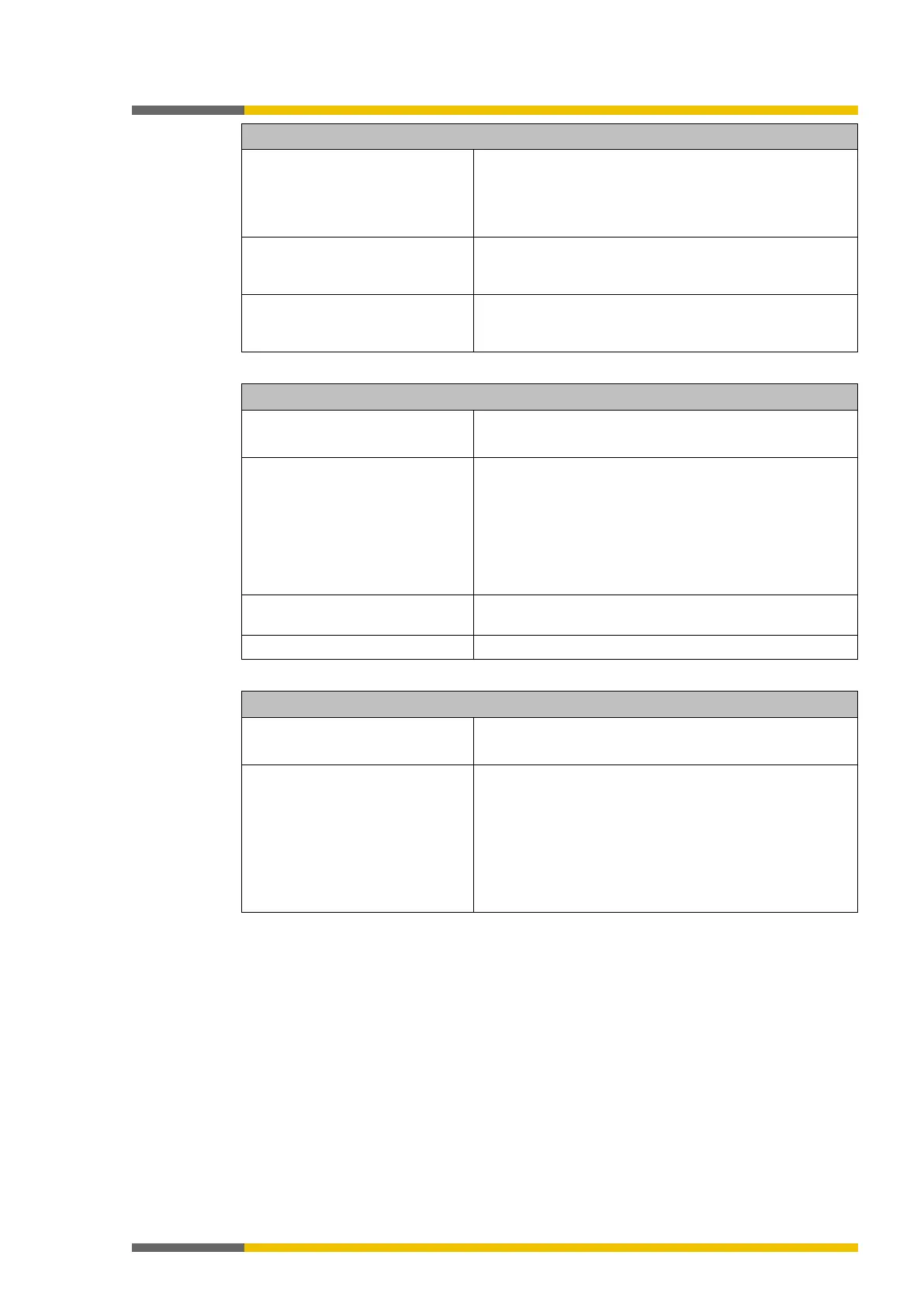

Selection list Determines the transmission method.

Value: Gateway reads from register

Column

Determines which data are to be written to the PLC or

read from it.

Mark the control boxes for the desired data sets for this

purpose.

You will find a detailed description of the data sets here:

Data transferred to the network (network input data sets)

[ch. 3.2, p. 18]

Column

Define from and to where in the PLC memory the selec-

ted data should be read and written.

Column heartbeat interval

Defines how often the data sets are to be updated.

Table 23: Settings in Area 3

The parameters define from and to where the data in the

Modbus-TCP network are to be read and written:

Maximum refresh time for PLC

Define the maximum rate (or the minimum time interval)

for transmitting the data sets to the PLC. This setting

depends on the processing speed of the PLC. Minimum =

10 ms, maximum = 65535 ms. The basic setting of 40 ms

is suitable for most PLC

Note: When these values are greater than the heartbeat

interval, the

will be slowed down to

Combine samosPLAN5+ with the samosPRO system and transmit the configuration.

More detailed information on the link to the controls: Software manual, chapter "Connect

with the safety control"

Loading...

Loading...