Operation

2303−1/A1

Winterthur Gas & Diesel Ltd.

1/ 2

Piston Rod Gland

1. General

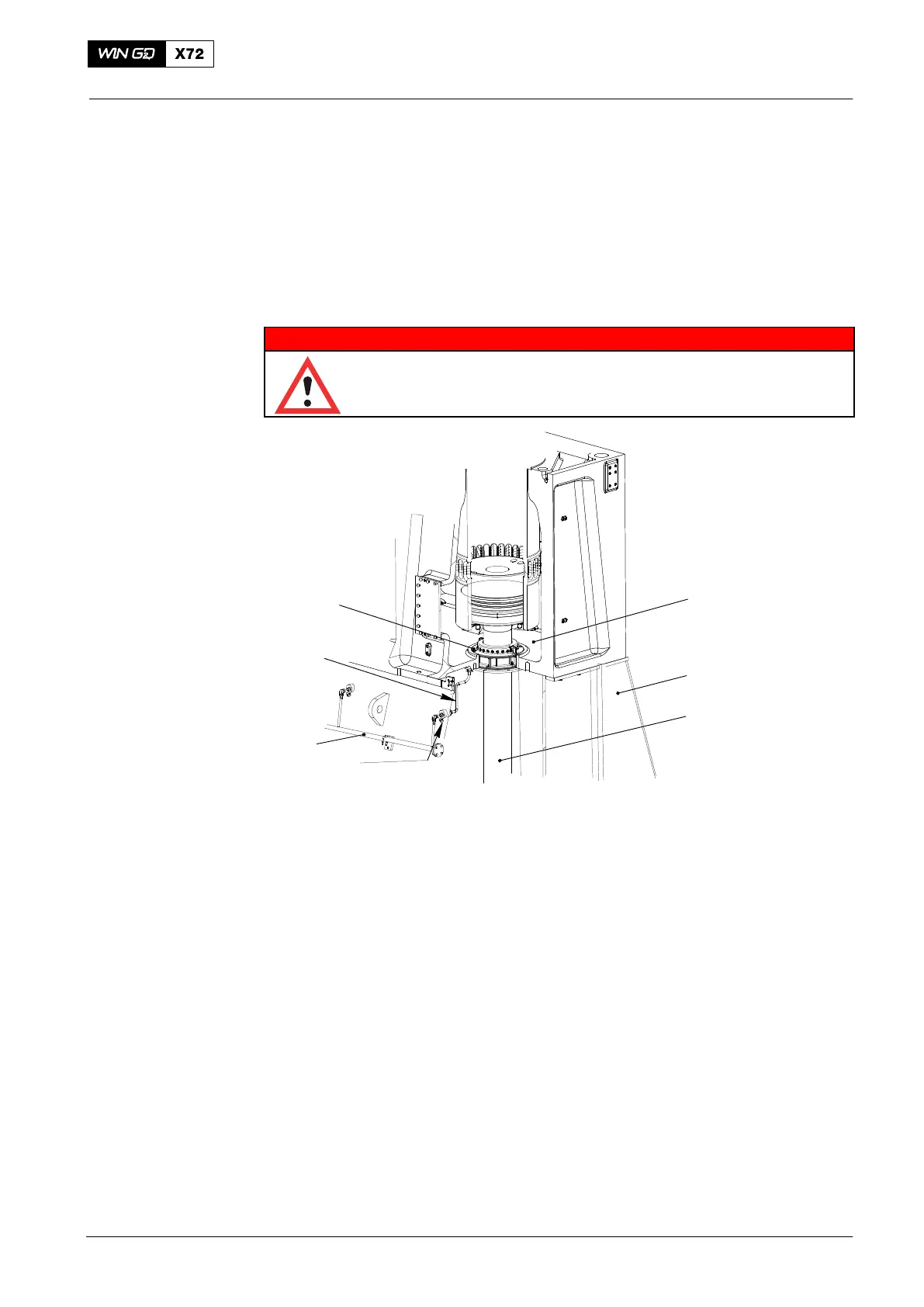

The piston rod gland (4, Fig. 1) keeps the dirty oil in the scavenge space (SS) and

prevents contamination of the bearing oil. Also, the piston rod gland seals the

scavenge air from the crankcase (1).

Damaged gaskets cause an increase in the quantity of oil in the leakage oil drain. You

use the sample port (3) to get an oil sample. You can measure this sample, and/or

send the sample to the laboratory to make an analysis.

WARNING

Danger: The leakage oil drain LD must not become clogged (see

0240−1. There is a dangerous risk of fire if the dirty oil does not

flow away from the area (see 0450−1).

WCH02291

2

SS

1

3

LP

LD

4

Fig. 1: Location of Piston Rod Gland Box

1 Crankcase SS Scavenge space

2 Piston rod LP Leakage oil pipe

3 Sample port LD Leakage oil drain

4 Piston rod gland

2. Function

During operation, the two scraper rings (12, Fig. 2) remove dirty oil from the piston

rod. The dirty oil flows through the oil bores (1) and collects in the bottom of the

scavenge space (SS). The dirty oil flows out through the leakage oil drain on the fuel

side.

The two gaskets (9) and (10) prevent the release of scavenge air into the crankcase.

The low scavenge air pressure is released through a vent in the plant.

The oil that flows through the relief passages (2) into the neutral space (3) flows into

the oil drain.

The four ring supports (4) hold the eight scraper rings (7) in position. The scraper

rings (7) remove bearing oil from the piston rod. This bearing oil flows through the

bearing oil drain (BD) to the crankcase.

The tension springs, (8) and (11), keep the scraper rings (7) and (12) against the

piston rod.

2015-03

Loading...

Loading...