Operation

5551−1/A1

Winterthur Gas & Diesel Ltd.

1/ 2

Servo Oil Pump

1. General

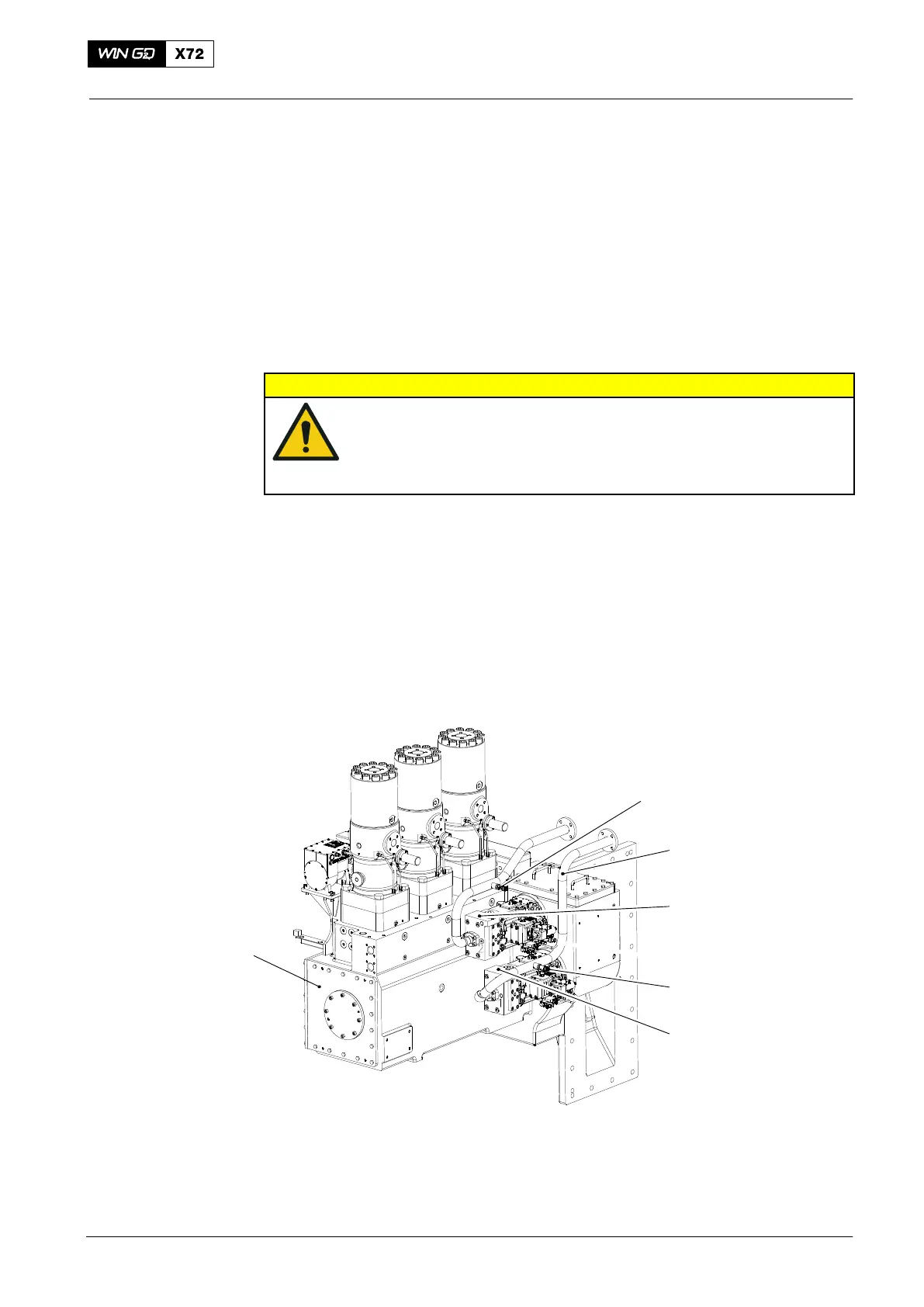

The servo oil pumps (3 and 5, Fig. 1) are attached to, and part of, the supply unit (6).

These pumps supply servo oil to open the exhaust valves.

For more data about the supply unit, see 5552-1.

The flow sensors (1 and 4), monitor the oil supply in each inlet pipe (2) of the servo oil

pumps. A malfunction of a servo oil pump will show in the alarm and monitoring

system.

2. Function

CAUTION

Damage Hazard: If a servo oil pump becomes defective, do not

operate the engine for too long. If the other pump becomes

defective, the engine cannot operate. You must replace the

defective servo oil pump as soon as possible (see the

Maintenance Manual 5552-1).

During usual operation, the servo oil pumps supply hydraulic pressure equally for the

full load range.

The nominal pressure value is related to the engine load. The electrically controlled

system adjusts the system pressure for the full load range, i.e. high pressure

(approximately 300 bar) at high engine load, and decreased pressure at low engine

load.

Note: If a servo oil pump cannot turn, the safety device (4, Fig. 2) will break.

This will prevent too much damage to the intermediate wheel (6).

If one pump becomes defective, the engine will continue to operate at full load.

For more data, see the Maintenance Manual 5551-2.

EXHAUST

SIDE

DRIVING

END

WCH01192

6

3

2

1

5

4

Fig. 1: Location of Servo Oil Pumps

1 Flow sensor FS2062A 4 Flow sensor FS2061A

2 Inlet pipe 5 Servo oil pump No.1

3 Servo oil pump No.2 6 Supply unit

2014

Loading...

Loading...