Operation9308−1/A1

Winterthur Gas & Diesel Ltd.

4/ 4

201

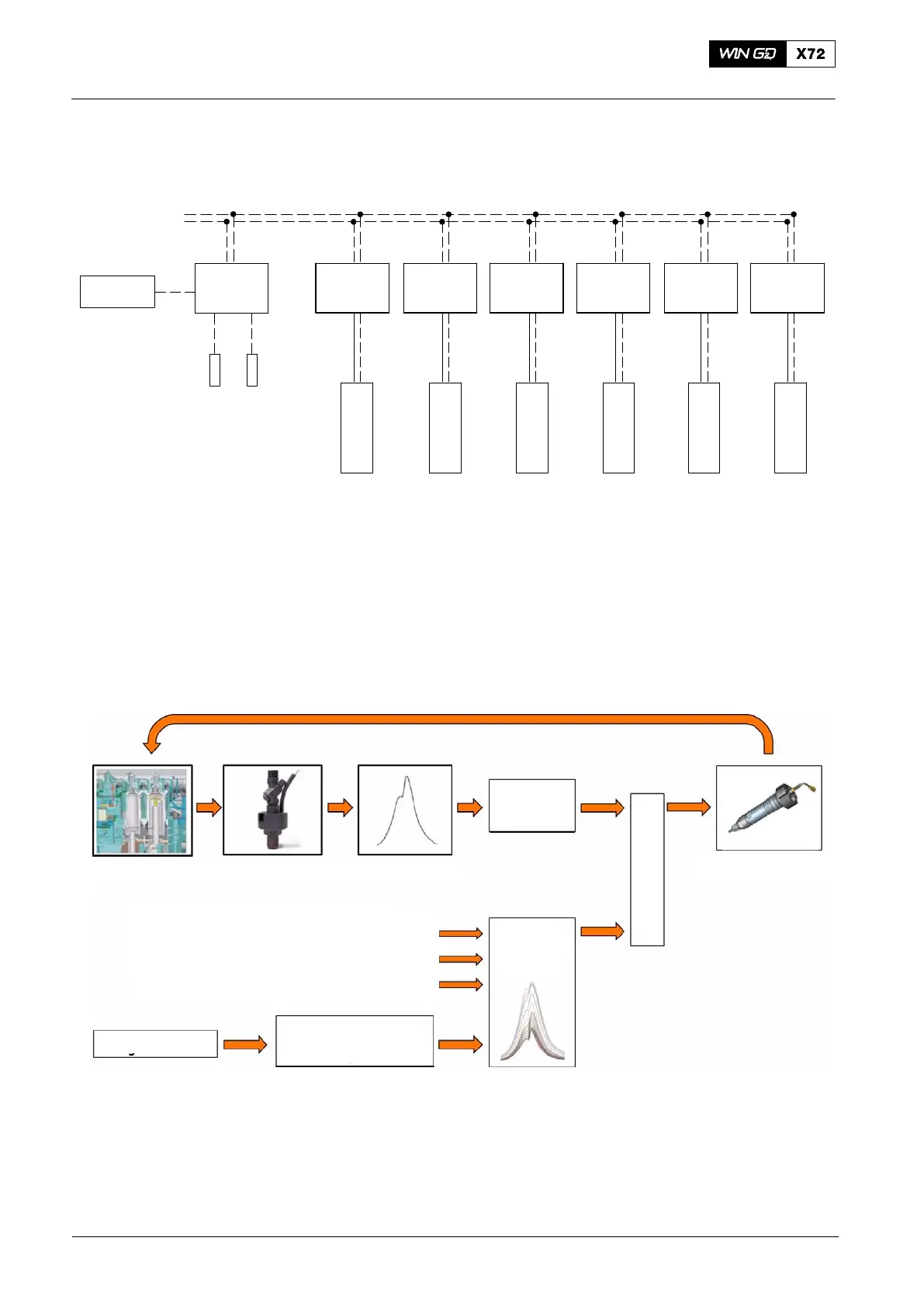

The cylinder pressure data of each cylinder is taken as an analogue input signal from

the pressure transducer into the ECS. For more data, see Fig. 3.

Barometric

pressure

IOM-10

Temperature sensor

(TC compressor inlet)

Temperature sensor

(Scavenge air receiver)

CCM−20

Cyl. 1

CCM−20

Cyl. 2

CCM−20

Cyl. 3

CCM−20

Cyl. 4

CCM−20

Cyl. 5

CCM−20

Cyl. 6

CAN System Bus

Pressure

Transducer 1

Pressure

Transducer 6

Pressure

Transducer 5

Pressure

Transducer 4

Pressure

Transducer 3

Pressure

Transducer 2

Power

Supply

DATA FOR

6 CYLINDERS

Fig. 3: Installation Schematic of the ICC System

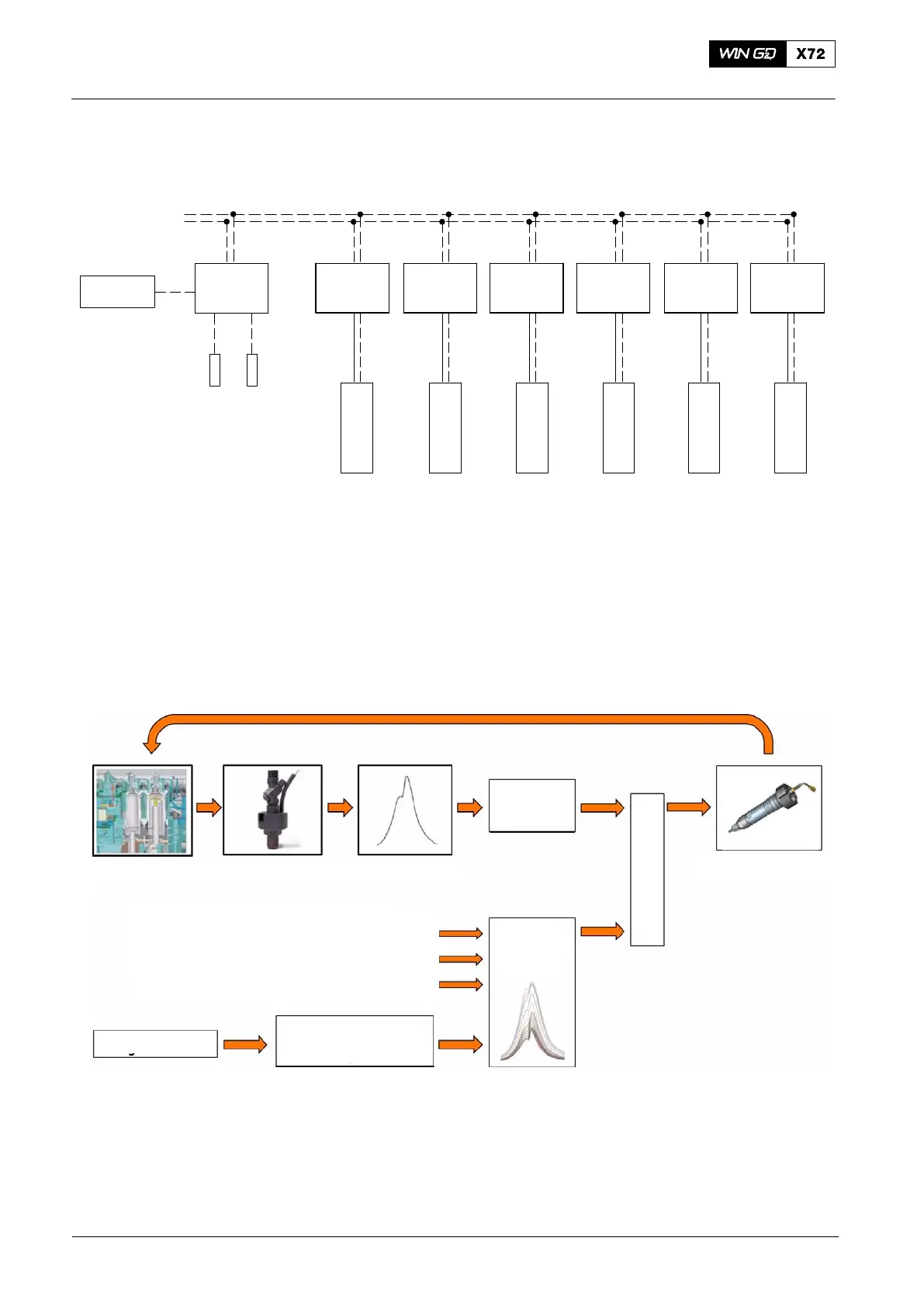

The ECS control system filters the signals from the sensors and then transmits these

signals to a controller. The measured value is adjusted to the correct set-point value

and is related to the engine load. This real-time site correction and

comparison is done for each engine cycle (see Fig. 4).

Setpoint

Correction

TC compressor inlet air temperature

Scavenge air temperature

TC compressor inlet pressure

Value

Firing Pressure

Setpoint

Engine Load

Comparison

Combustion Cylinder pressure evaluation

Injection start offset

Fig. 4: Control schematic of the ICC System

2014

Loading...

Loading...