4.7 Operation Sequence

4-63

4

4.7 Operation Sequence

This section describes outline of the operation sequence. Refer to 4.3 Main Commands and 4.4

Subcommands for details of command functions and settings.

4.7.1 Operation Sequence for Managing Parameters Using a Controller

The following describes the operation sequence for managing parameters using a controller.

The controller manages the necessary parameters, and transfers them when the power is

turned ON. With this operation sequence, the settings can be managed by the controller even

when the SERVOPACK is replaced.

* If communication disconnects normally, the NOP command is sent. If communication does not

disconnect normally, the DISCONNECT command is sent for two or more communications

cycles prior to connection, then the CONNECT command is sent.

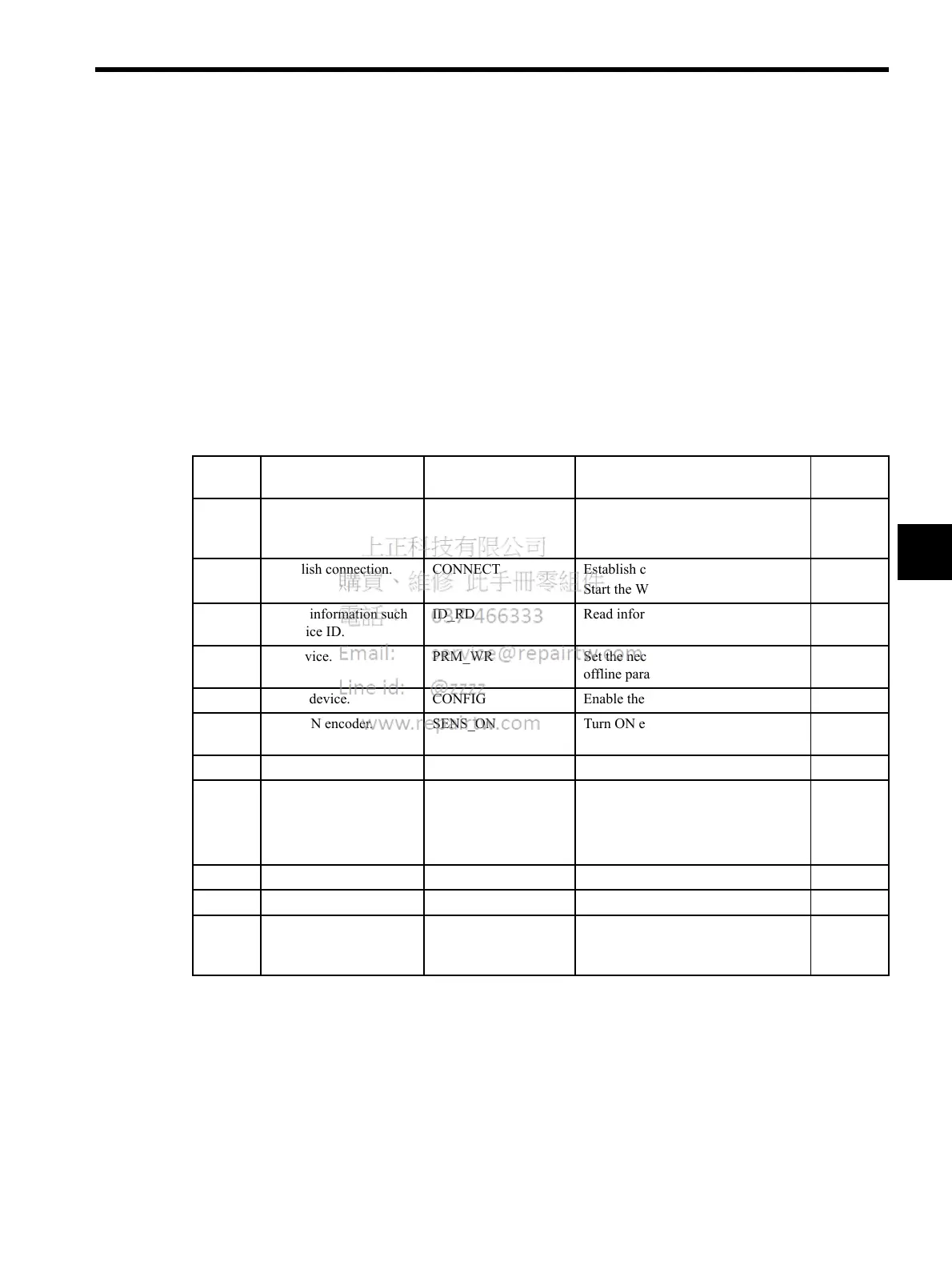

Table 4.4 Operation Sequence for Managing Parameters Using a Controller

Proce-

dure

Item Command Description Phase

1 Turn ON control and

main circuit power sup-

plies.

NOP/DISCONNECT* Turn ON power supplies.

1

2 Establish connection. CONNECT Establish communications.

Start the WDT count.

2 or 3

3 Check information such

as device ID.

ID_RD Read information such as device type.

2 or 3

4 Set device. PRM_WR Set the necessary parameters such as

offline parameters.

2 or 3

5 Set up device. CONFIG Enable the parameter settings.

2 or 3

6 Turn ON encoder. SENS_ON Turn ON encoder and obtain the posi-

tion data.

2 or 3

7 Operate main circuit. SV_ON Turn ON servomotor.

2 or 3

8 Start operation.

.

.

.

.

.

.

Start operation.

.

.

.

2 or 3

9 Turn OFF main circuit. SV_OFF Turn OFF servomotor.

2 or 3

10 Disconnect connection. DISCONNECT Disconnect communications.

4

to 1

11 Turn OFF control and

main circuit power sup-

plies.

− Turn OFF power supplies.

5

Loading...

Loading...