9.2 Troubleshooting with No Alarm Display

9-21

9

9.2 Troubleshooting with No Alarm Display

Refer to the tables below to identify the cause of a problem which causes no alarm display and

take the remedy described.

Turn OFF the servo system power supply before commencing the shaded procedures.

Contact your Yaskawa representative if the problem cannot be solved by the described proce-

dures.

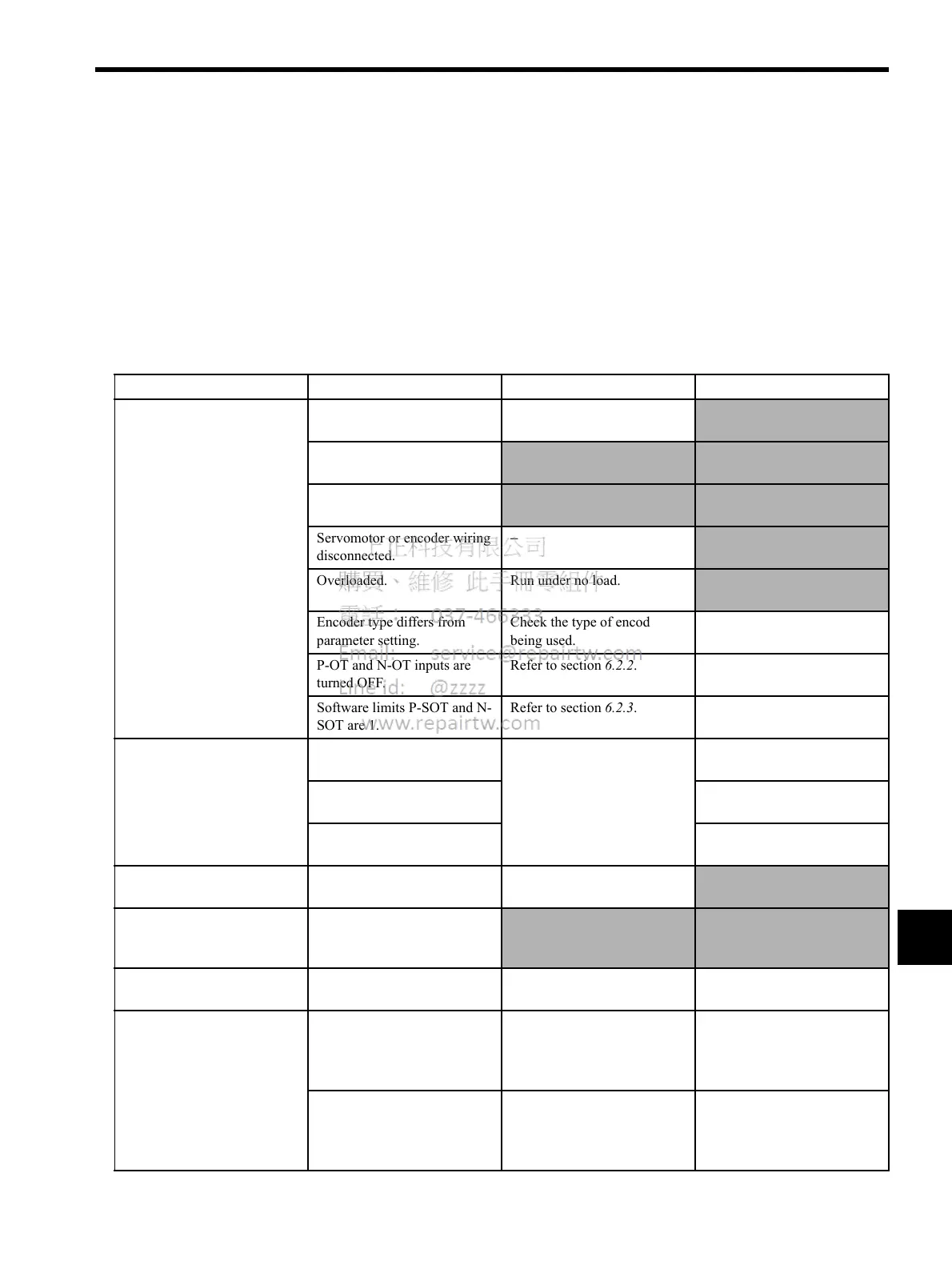

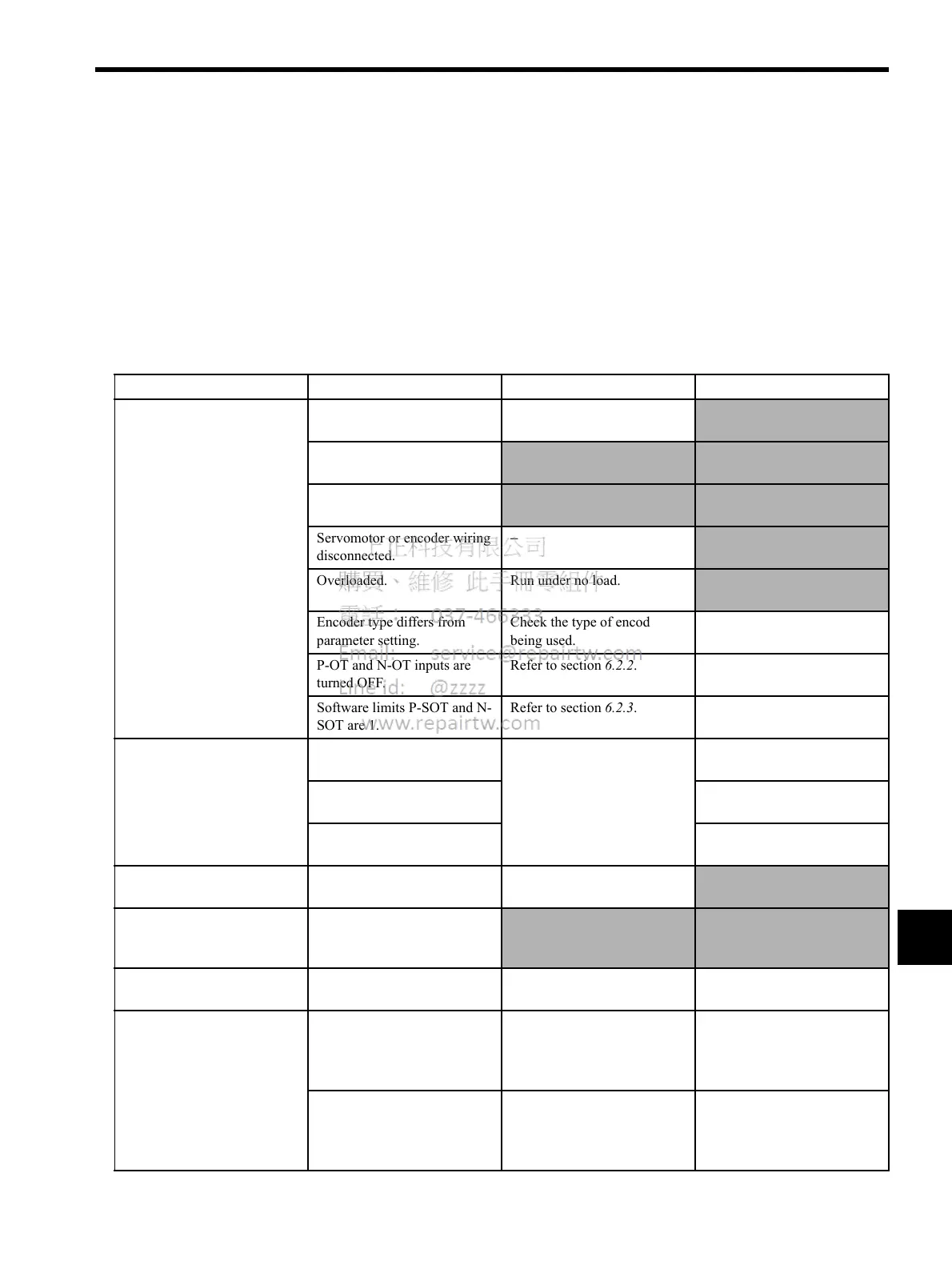

Table 9.1 Troubleshooting Table with No Alarm Display

Symptom Cause Inspection Remedy

Servomotor Does Not Start Power is not turned ON. Check voltage between power

supply terminals.

Correct the power circuit.

Loose connection. Check terminals of connectors

(CN1, CN2).

Tighten any loose parts.

Connector (CN1) external wir-

ing is incorrect.

Check connector (CN1) exter-

nal wiring

Refer to connection diagram

and correct wiring.

Servomotor or encoder wiring

disconnected.

−

Reconnect wiring.

Overloaded. Run under no load.

Reduce load or replace with

larger capacity servomotor.

Encoder type differs from

parameter setting.

Check the type of encoder

being used.

Set parameter Pn002.2 to the

encoder type being used.

P-OT and N-OT inputs are

turned OFF.

Refer to section 6.2.2. Turn P-OT and N-OT input

signals ON.

Software limits P-SOT and N-

SOT are 1.

Refer to section 6.2.3. Operate the servomotor within

the software limits.

Servomotor Does Not Run Motion commands have not

been sent.

Check using

MECHAROLINK-II

communications or the

MECHATROLINK-II monitor.

Send the motion commands.

SV_ON command has not

been sent.

Send the SV_ON command.

SENS_ON command has not

been sent.

Send the SENS_ON command.

Servomotor Moves Instanta-

neously, then Stops

Servomotor or encoder wiring

incorrect.

−

Refer to chapter Chapter 3

and correct wiring.

Servomotor Speed Unstable Wiring connection to motor is

defective.

Check connection of power

lead (phases U, V, and W) and

encoder connectors.

Tighten any loose terminals or

connectors.

Servomotor Vibrates at Ap-

proximately 200 to 400 Hz.

Speed loop gain value is too

high.

− Reduce speed loop gain

(Pn100) preset value.

High Rotation Speed Over-

shoot on Starting and Stop-

ping.

Speed loop gain value is too

high.

− Reduce speed loop gain

(Pn100) preset value.

Increase integration time con-

stant (Pn101).

Speed loop gain is too low

compared to position loop

gain.

− Increase speed loop gain

(Pn100).

Reduce the integration time

constant (Pn101).

Loading...

Loading...