6.3 Settings According to Host Controller

6-21

6

Electronic Gear Setting Examples

The following examples show electronic gear settings for different load mechanisms.

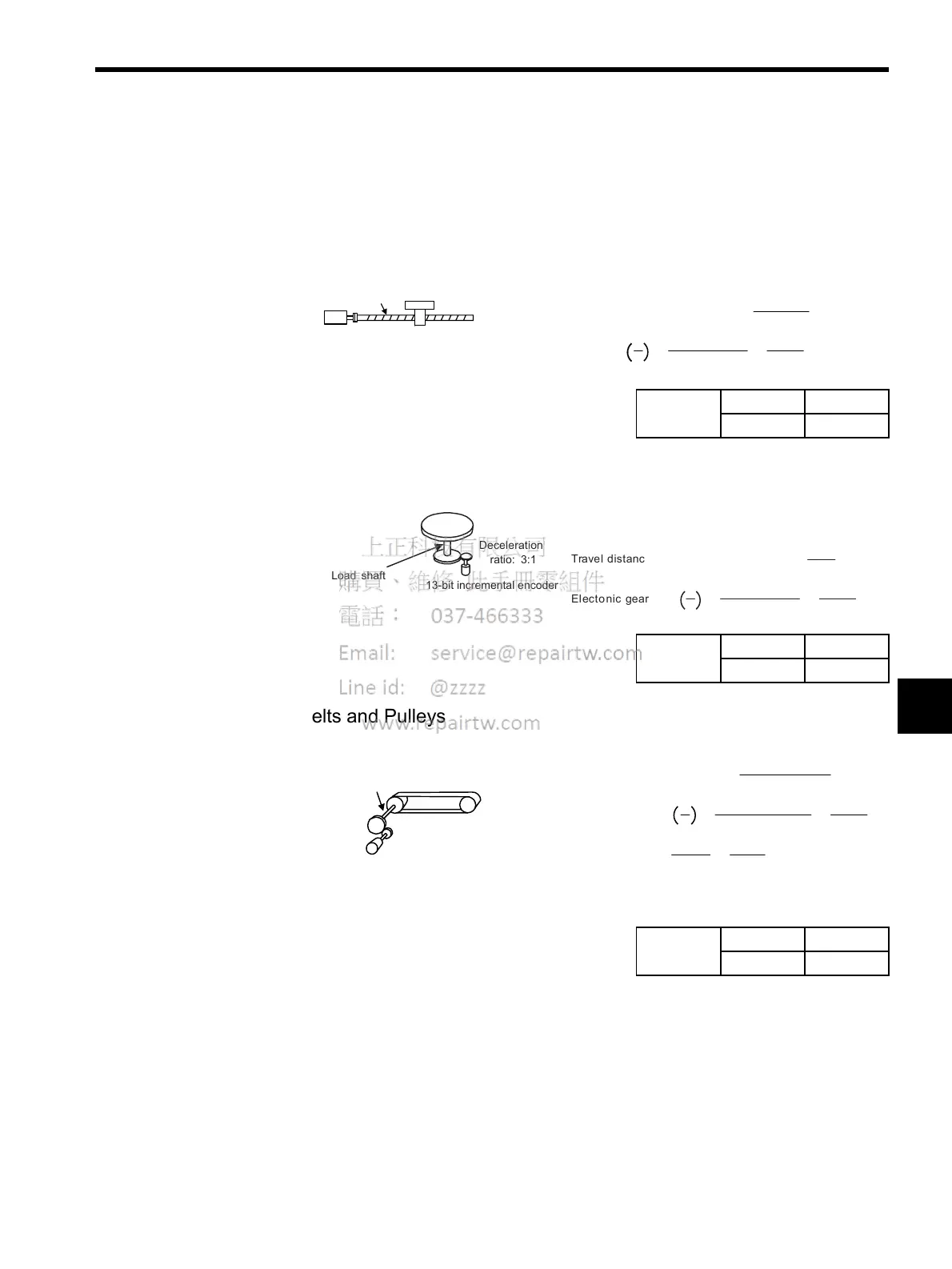

Ball Screws

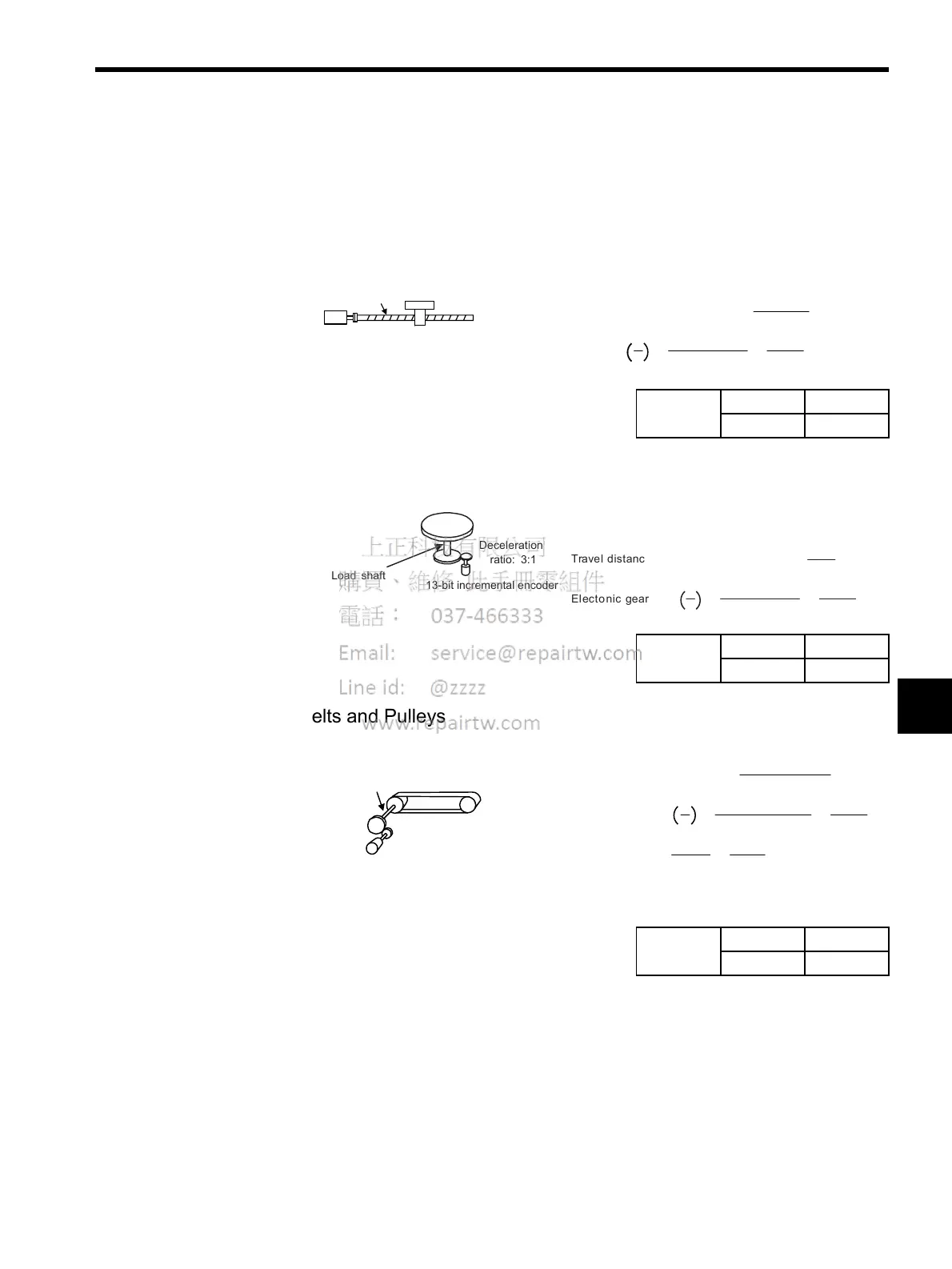

Circular Tables

Belts and Pulleys

Preset

Values

Pn202 8192

Pn203 6000

Preset

Values

Pn202 24576

Pn203 3600

Preset

Values

Pn202 49152

Pn203 61810

Ball screw pitch: 6mm (0.24 in)13-bit incremental

encoder

Load shaft

Reference unit: 0.001 mm (0.00004 in)

Travel distance per load shaft revolution =

6mm

0.001 mm

= 6000

Electronic gear ratio

B

A

=

2048

×

4 × 1

6000 × 1

=

Pn202

Pn203

13-bit incremental encoder

Load shaft

Travel distance per load shaft revolut ion =

360

°

0.1

°

= 3600

Electonic gear ratio

B

A

=

2048 × 4 × 3

3600 × 1

=

Pn202

Pn203

Reference unit: 0.1

°

Deceleration

ratio: 3:1

Load shaft

Travel distance per load shaft revolution =

3.14 × 100 mm

0.0254 mm

= 12362

Electronic gear ratio

B

A

=

1024 × 4 × 2.4

12362 × 1

=

Pn202

Pn203

Deceleration

ratio: 2.4:1

Reference unit: 0.0254 mm (0.0010 in)

Pulley diameter:

φ

100 mm

Set a PG dividing ratio equivalent

to 1024 P/R for the absolute

encoder.

=

9830 .4

1236 2

=

49152

61810

Loading...

Loading...