Installation

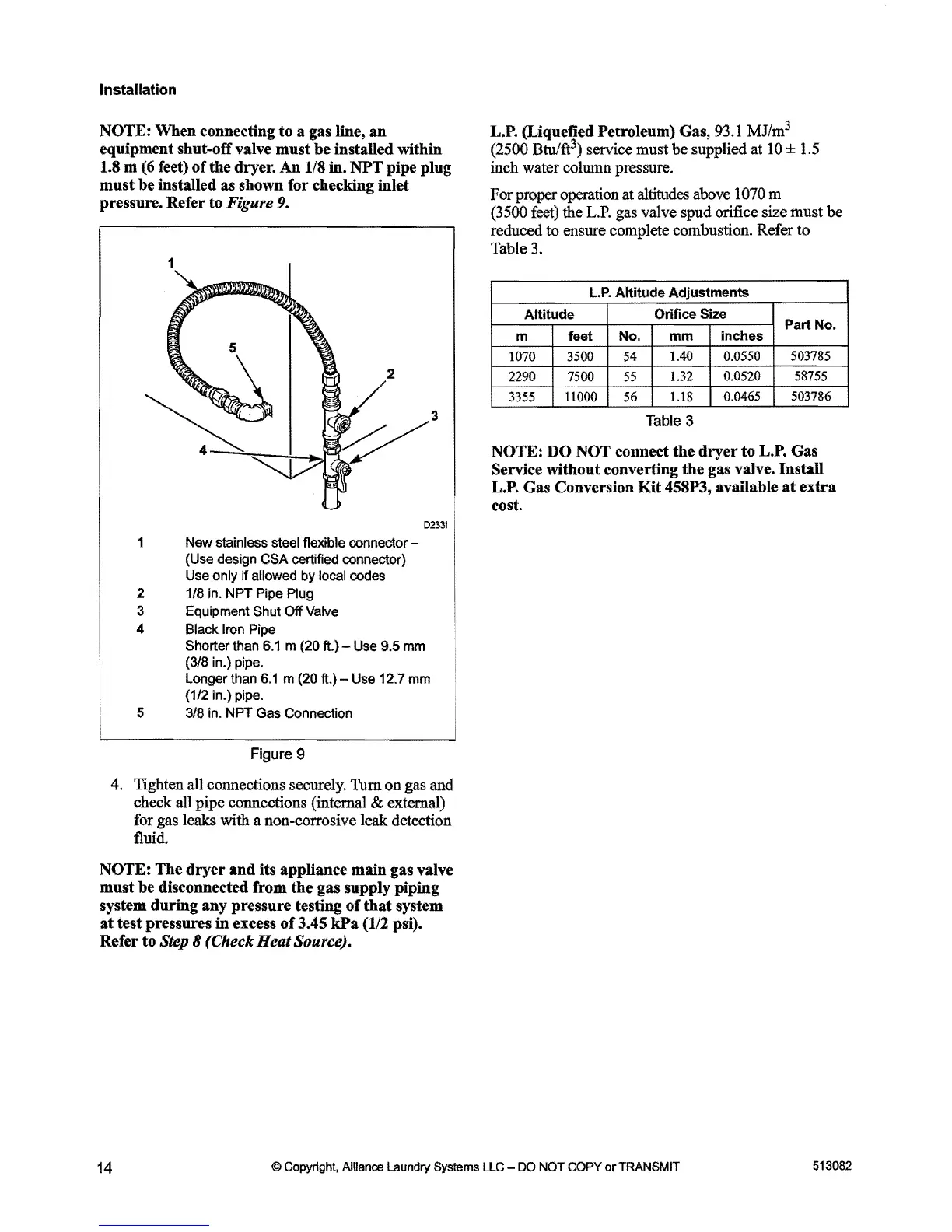

NOTE: When connecting

to

a gas line,

an

equipment shut-off valve

must

be

installed within

1.S m

(6

feet)

of

the dryer.

An

l/S

in.

NPT

pipe plug

must

be

installed as shown for checking inlet

pressure. Refer to

Figure 9.

1

2

1

2

3

4

5

New stainless steel flexible connector -

(Use design CSA certified connector)

Use only

jf

allowed by local codes

1/8 in. NPT Pipe Plug

Equipment Shut

Off

Valve

Black Iron Pipe

D2331

Shorter than

6.1

m (20

ft.)-

Use 9.5

mm

(318

in.) pipe.

Longer than

6.1

m (20 ft.) - Use 12.7 mm

(1/2 in.) pipe.

318

in. NPT Gas Connection

Figure 9

4. Tighten all connections securely.

Tum

on

gas and

check all pipe connections (internal & external)

for gas leaks with a non-corrosive

leak:

detection

fluid.

NOTE:

The

dryer

and

its appliance main gas valve

must

be

disconnected from the gas supply piping

system

during

any pressure testing

of

that

system

at

test pressures

in

excess

of

3.45

kPa

(1/2 psi).

Refer to

Step 8 (Check Heat Source).

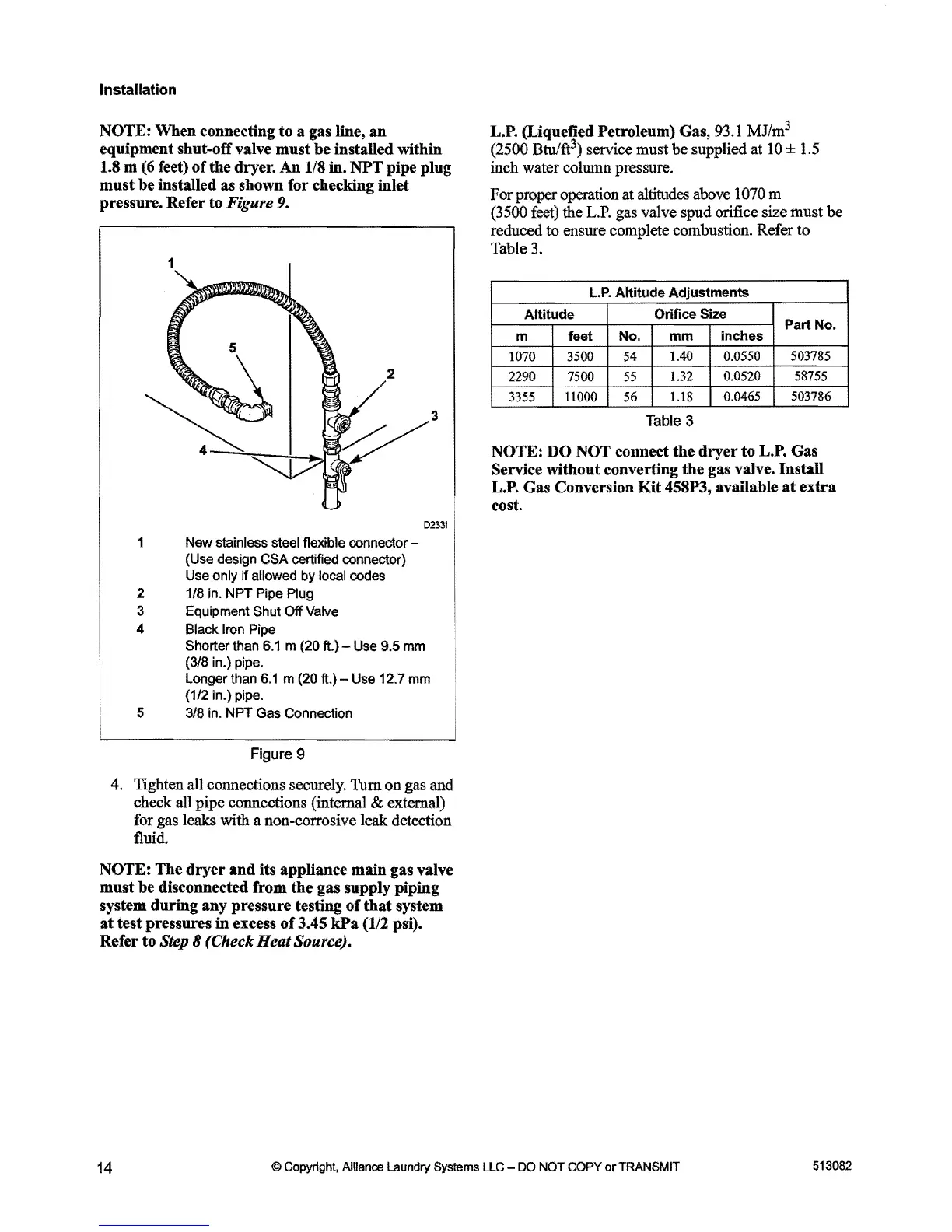

L.P. (Liquefied Petroleum) Gas, 93.1

MJ/m

3

(2500

Btu/f

t

3)

service must

be

supplied at

10

± 1.5

inch water column pressure.

For proper operation at altitudes above 1070 m

(3500 feet) the

L.P.

gas valve spud orifice size must

be

reduced to ensure complete combustion. Refer to

Table 3.

L.P.

Altitude Adjustments

Altitude

Orifice Size

Part No.

m

1070

503785

2290

58755

3355

0.0465

503786

NOTE: DO NOT connect the

dryer

to

L.P. Gas

Service without converting

the

gas valve. Install

L.P. Gas Conversion

Kit

45SP3, available

at

extra

cost.

14

©

Copyright.

Alliance

Laundry

Systems

LLC

-

DO

NOT

COPY

or

TRANSMIT

513082

Loading...

Loading...