Maintanance, Service, and Troubleshooting

Canrig Drilling Technology Ltd. 6-15

1000-day Inspection and Maps

An inspection of the Catwalk is recommended every 1,000 days so the equipment can be properly

maintained and to mitigate safety risks and component failure. The 1000-day Inspection Report maintains

a checklist of items that require visual and/or magnetic particle inspection (MPI) and can be a useful record

of comments or issues.

The diagrams in the Inspection Indication Maps show the areas of inspection. The areas that require

magnetic particle inspection are highlighted within the diagrams to indicate where to focus the inspection.

Refer to the appropriate ASTM document in order to correctly conduct all inspections, including the MPI.

This section is available on the Canrig CD-ROM as a standalone file that can be quickly printed to record

findings during an inspection. The filename is:

13-003_PC3000_26-in_1000-day_Inspection_Rpt.pdf

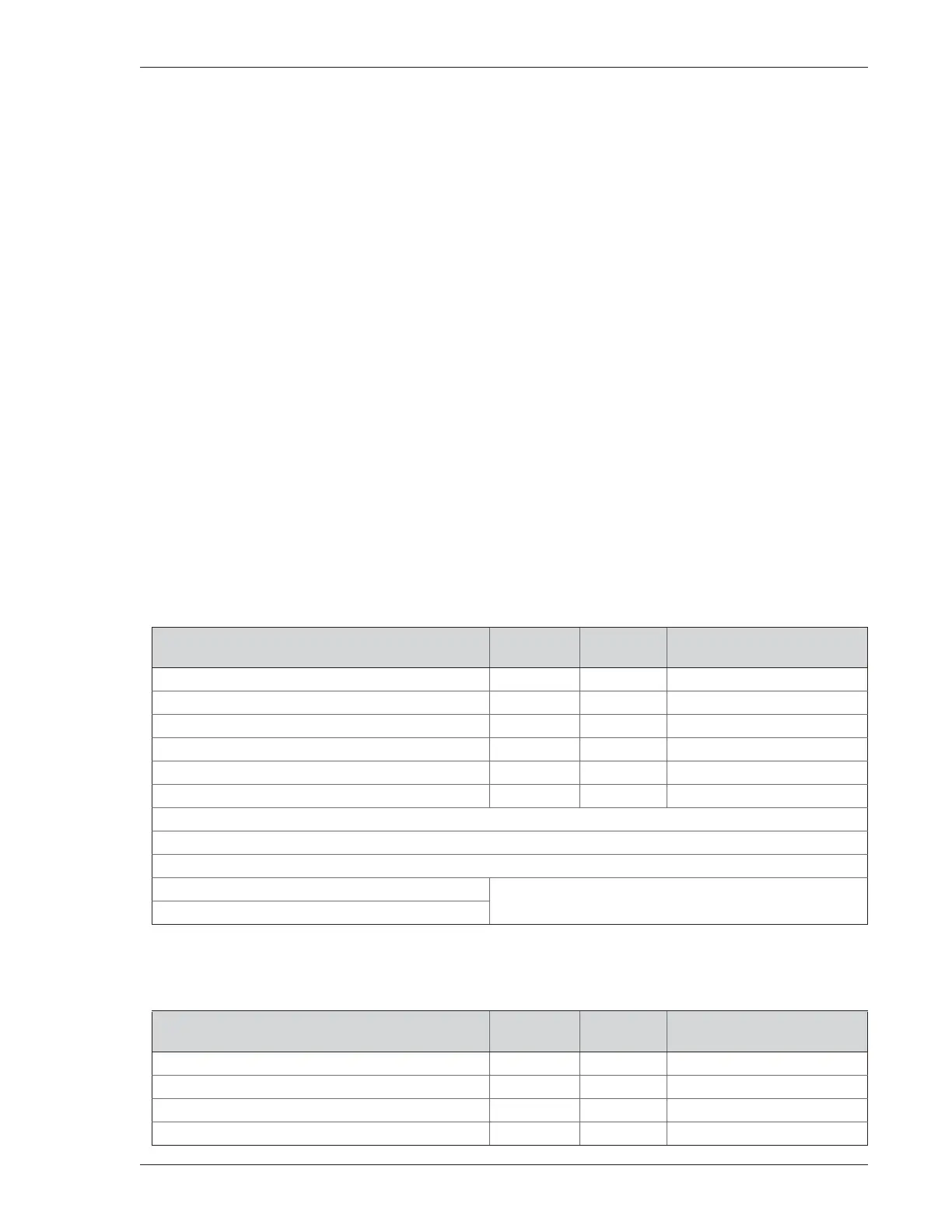

1000-day Inspection Report Checklists

Rig #: _______________ Date: ___/___/____ Location: _________________ Running Hours: _______

Inspect the following after the 30-point inspection. Look for any signs of wear or damage. Check Pass

or cross Fail in each box. Please enter comments on all items checked Fail.

Catwalk Base Inspection

Comments

Skid Roll Ends MPI

Ramp Pivot Posts MPI

Pipe Rack Arm Mounts/Hitch Blocks MPI

Carrier Roller Channels Visual

Pipe Indexers Mount Plates Visual

Pipe Rack Arms Visual

Notes:

Completed by:

Signature:

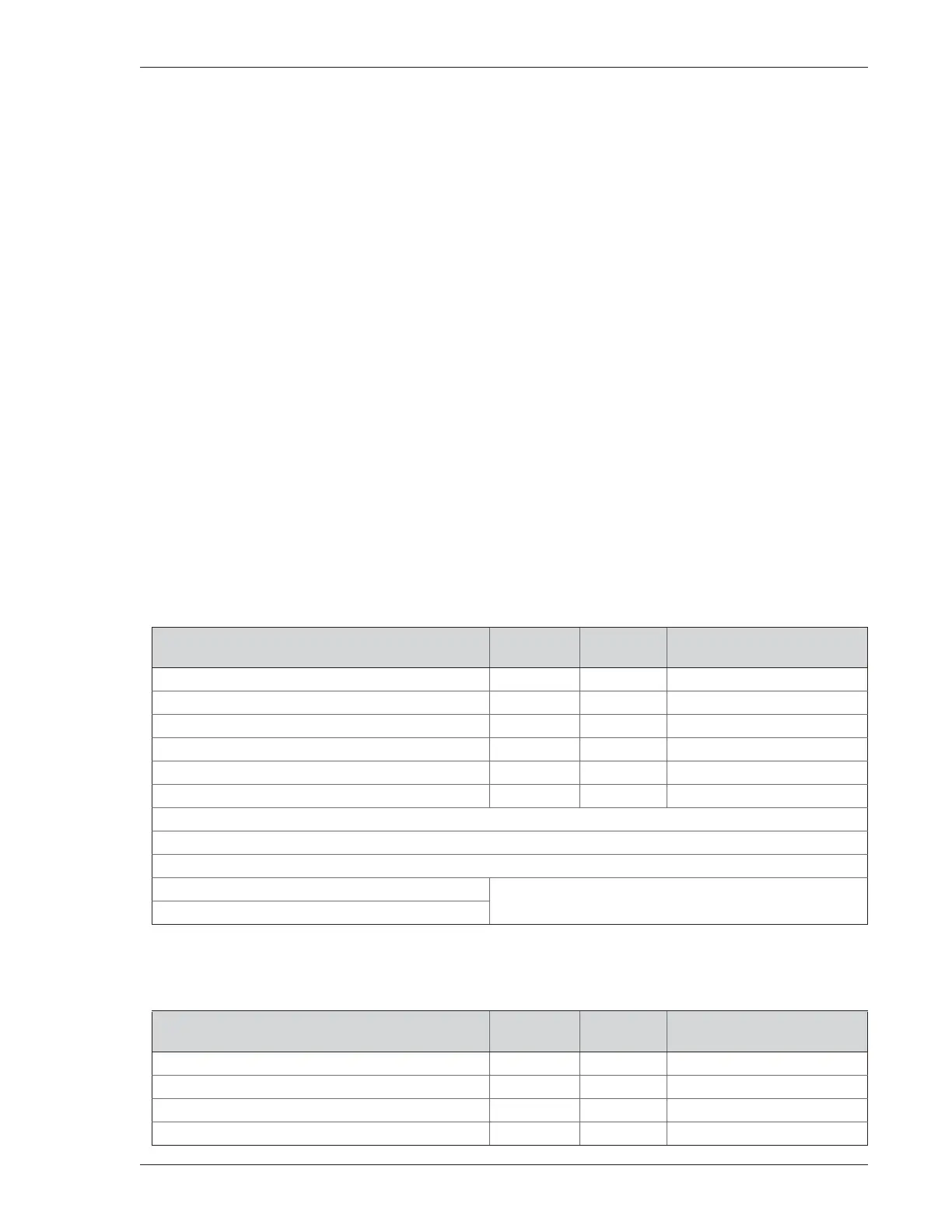

Ramp Inspection

Comments

Ramp Pivot Posts MPI

Carrier Roller Guide Channels Visual

Ramp Sheave Support Plates Visual

Ramp Sheaves Visual

Loading...

Loading...