Maintanance, Service, and Troubleshooting

Canrig Drilling Technology Ltd. 6-3

3. On Catwalks fitted with a drive chain skate winch, inspect the drive chain for wear and possible

sprocket looseness. Ensure the chain master link is properly attached and the chain is well lubricated

and tensioned. The chain should have between 1/4” to 1/2” droop between sprockets on the slack

side.

4. Either before each tripping run or monthly, inspect the skate winch cable and drum for signs of wear.

Check for broken wire in the cable and excessive grooving in the drum.

5. Check the carrier lift winch cables for signs of wear. Check for broken wires in the cable. Ensure cables

are not crossed and are riding in the correct groove on the main winch drum.

6. Inspect the carrier lift winch motor and brake hydraulic lines for signs of wear and leaks. For detailed

information and maintenance on the carrier lift winch, refer to the Lantec

®

Manual.

7. Check inside and around the Catwalk for signs of hydraulic leaks.

Greasing Procedure

Weekly Greasing

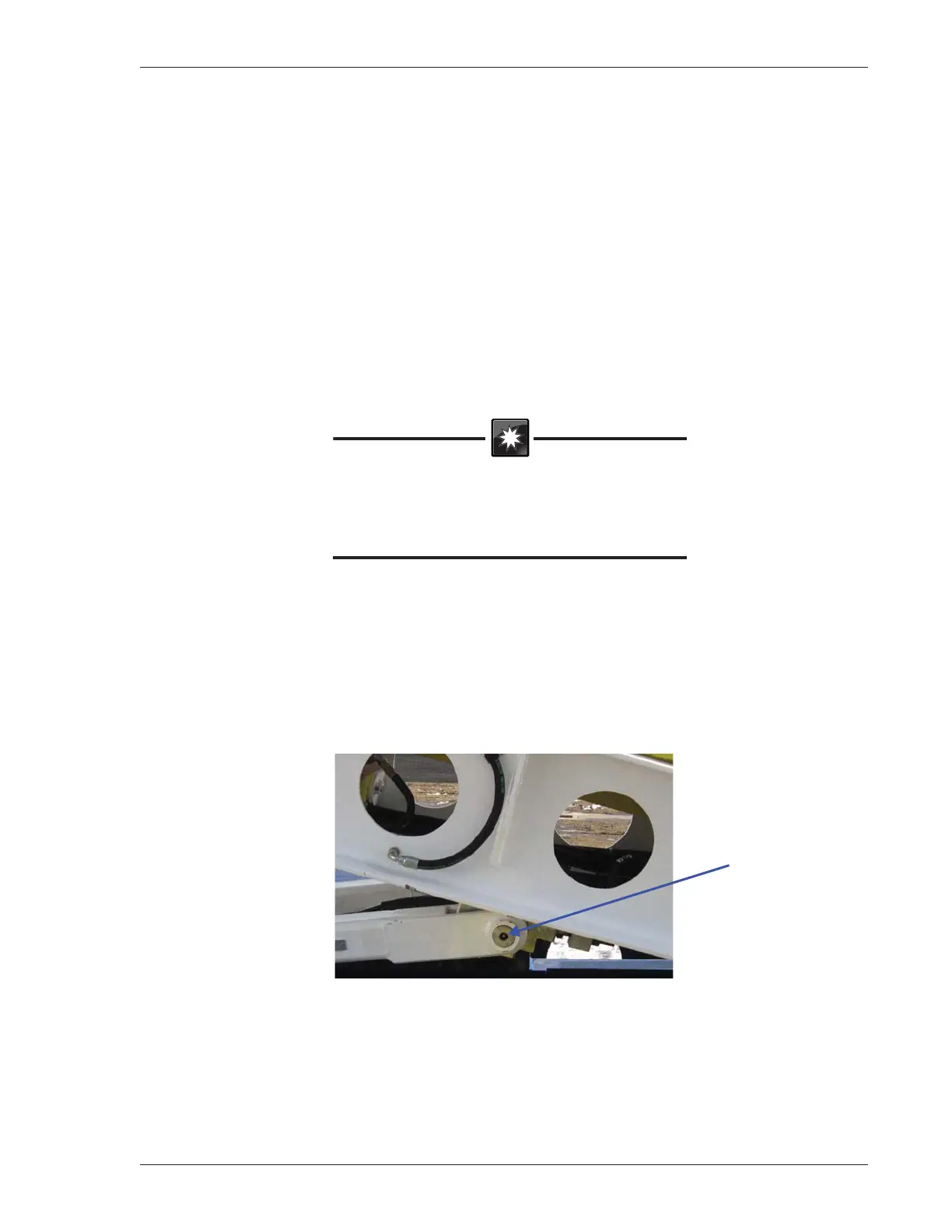

1. Use a multi–purpose lithium complex grease that complies with N.L.G.I. Classification No. 1 or No. 2 to

grease each grease zerk on the lift arm shaft (Figure 6-3).

Figure 6-3: Lift Arm Grease Points

Warning!

Hydraulic pressure in the lines can reach 5,000 psi.

Ensure all leaks and frayed or damaged lines are

corrected immediately.

Grease Point

(Both Sides)

Loading...

Loading...