Chapter 2 Operating Principles

2-1.

Operation of Each Mechanism

2-11 CL-E700 series

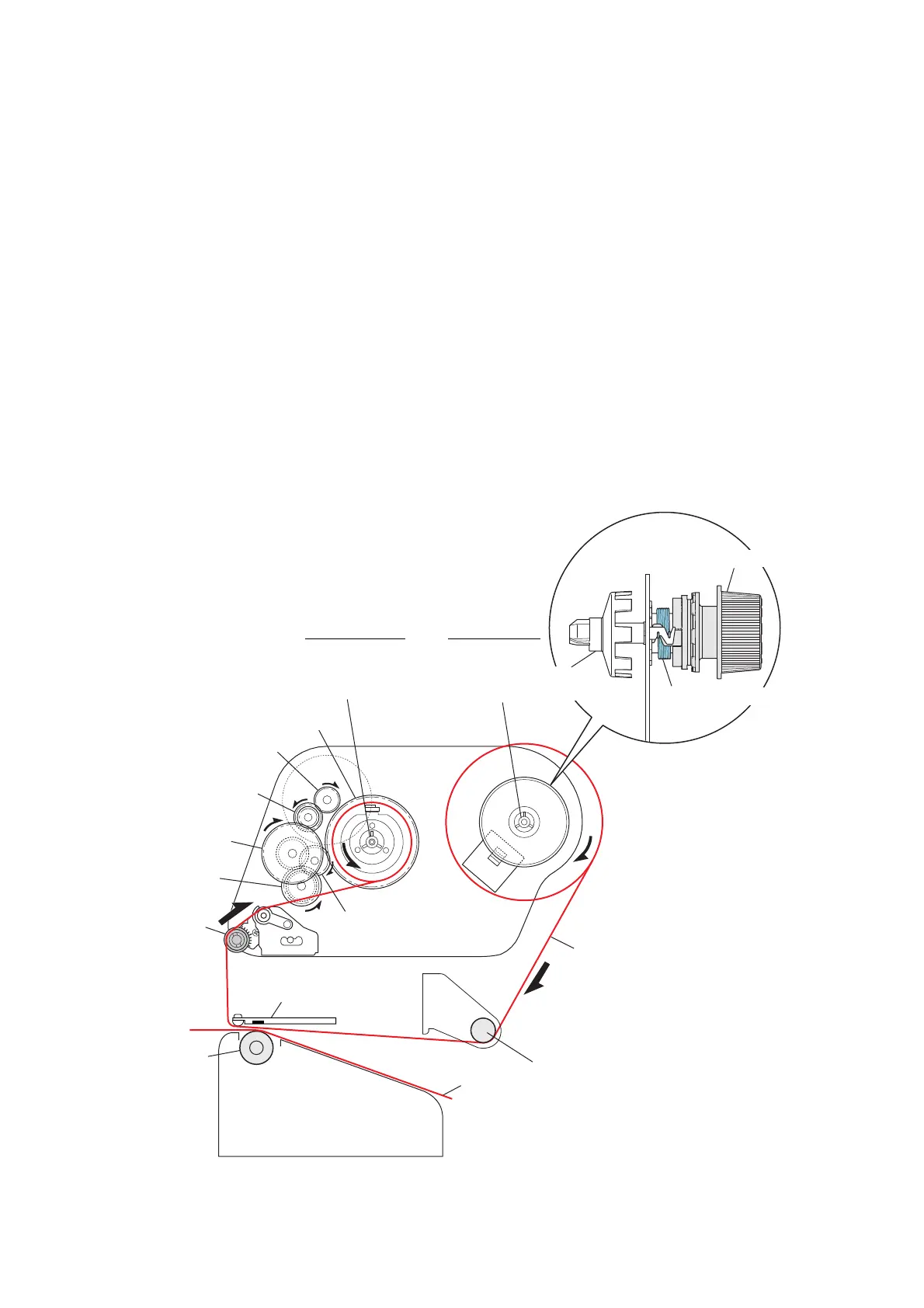

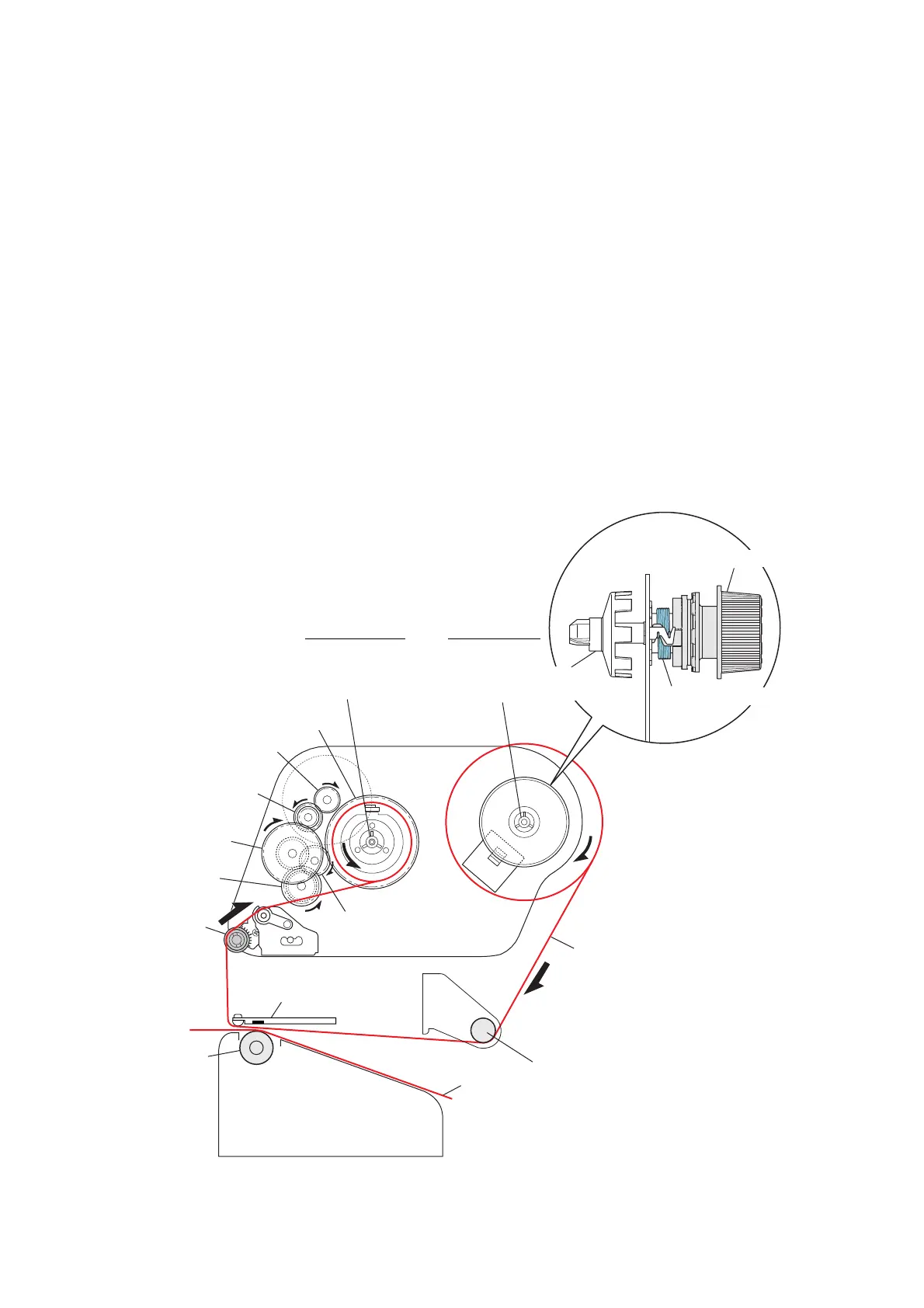

2-1-4. Ribbon Feed Mechanism

The major components of the ribbon feed mechanism are:

(a) SA Ribbon Motor F (d) SA Ribbon Tension Unit R

(b) SA Ribbon Tension Shaft F (e) Ribbon gear train

(c) SA Ribbon Sensor (Ribbon tension sensor)

Ink ribbon is set to the take-up reel (SA Holder R Shaft) and the supply reel (Holder Ribbon Shaft

Encoder) via the supplied ribbon holders.

As the ribbon motor “SA Ribbon Motor F” on the take-up side turns in the direction shown in the

figure, the take-up reel (Gear 5F Ribbon) is driven via the “Gear Reduction Ribbon 1”, “Gear 2

Ribbon”, “Gear 3 Ribbon” and “Gear 4 Ribbon”.

The ribbon is supplied from the supply reel via the “Roller Ribbon Guide R” and “SA Ribbon

Tension Shaft F”, and then taken up.

A back tension generating mechanism that is formed by the “SA Ribbon Tension Unit R” and

“Sprint Ribbon Return R” is directly connected to the supply reel. When the ribbon is supplied, the

back tension generating mechanism gives an appropriate back tension to the ribbon.

Gear 5F Ribbon

Gear Reduction Ribbon 1

Gear 2 Ribbon

Gear 3 Ribbon

SA Ribbon Motor F

SA Ribbon

Tension Shaft F

Media

Roller Ribbon Guide R

SA Platen

SA Head

Taku-up Side

Supply Side

Spring Ribbon Return R

SA Ribbon Tension Unit R

Take-up Reel

(SA Holder R Shaft)

[Back Tension Generation Mechanism]

Gear 4 Ribbon

Supply Reel

(Holder Ribbon Shaft Encoder)

[Right side view]

Ribbon

Loading...

Loading...