V1108, 3.1

3. Tool configuration and bend sequence

3.1. Introduction

This chapter describes how to program a tool configuration and a bend sequence for a

product. When finished, a product program can be generated with this information.

3.2. Tool configuration

3.2.1. Standard procedure

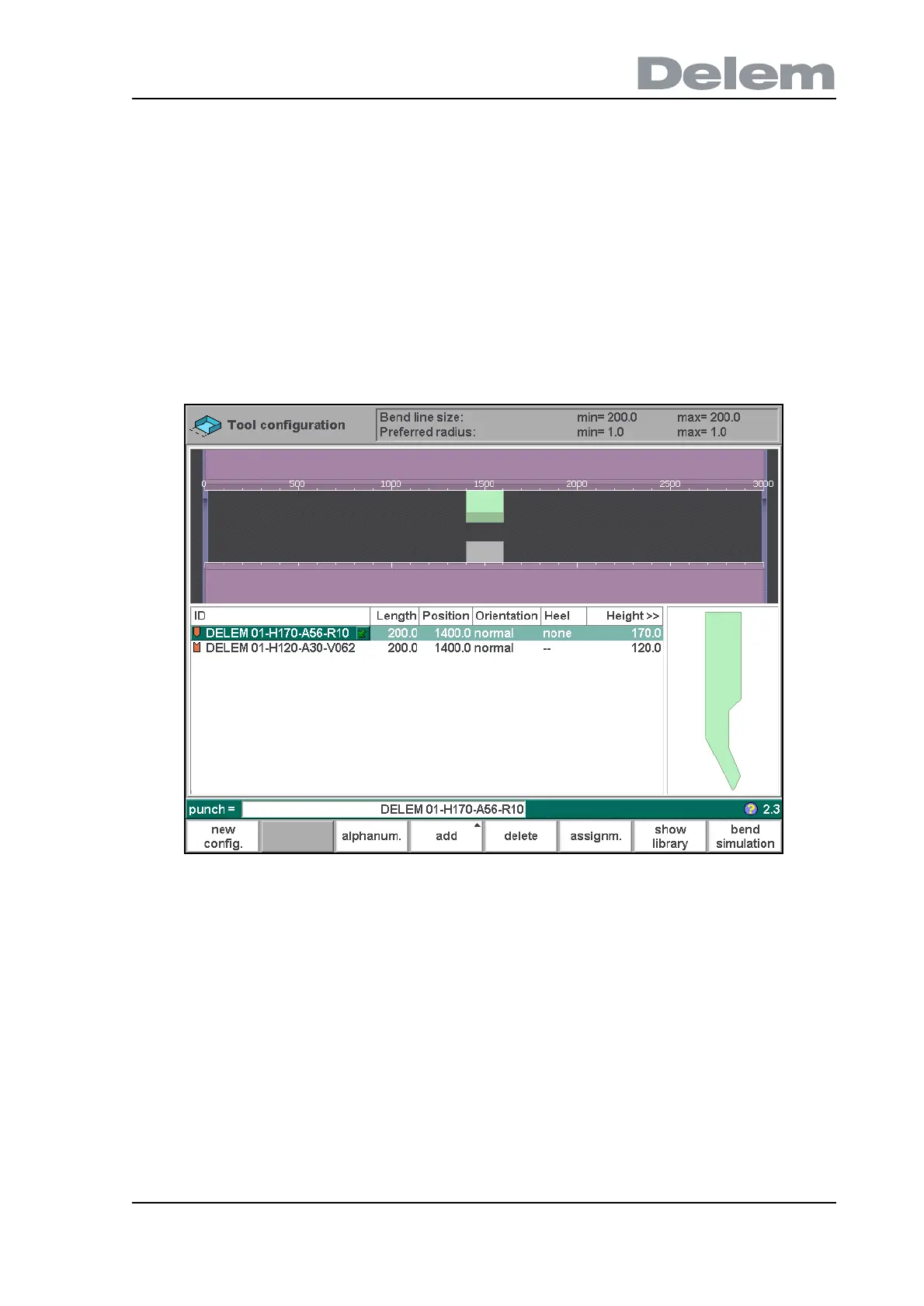

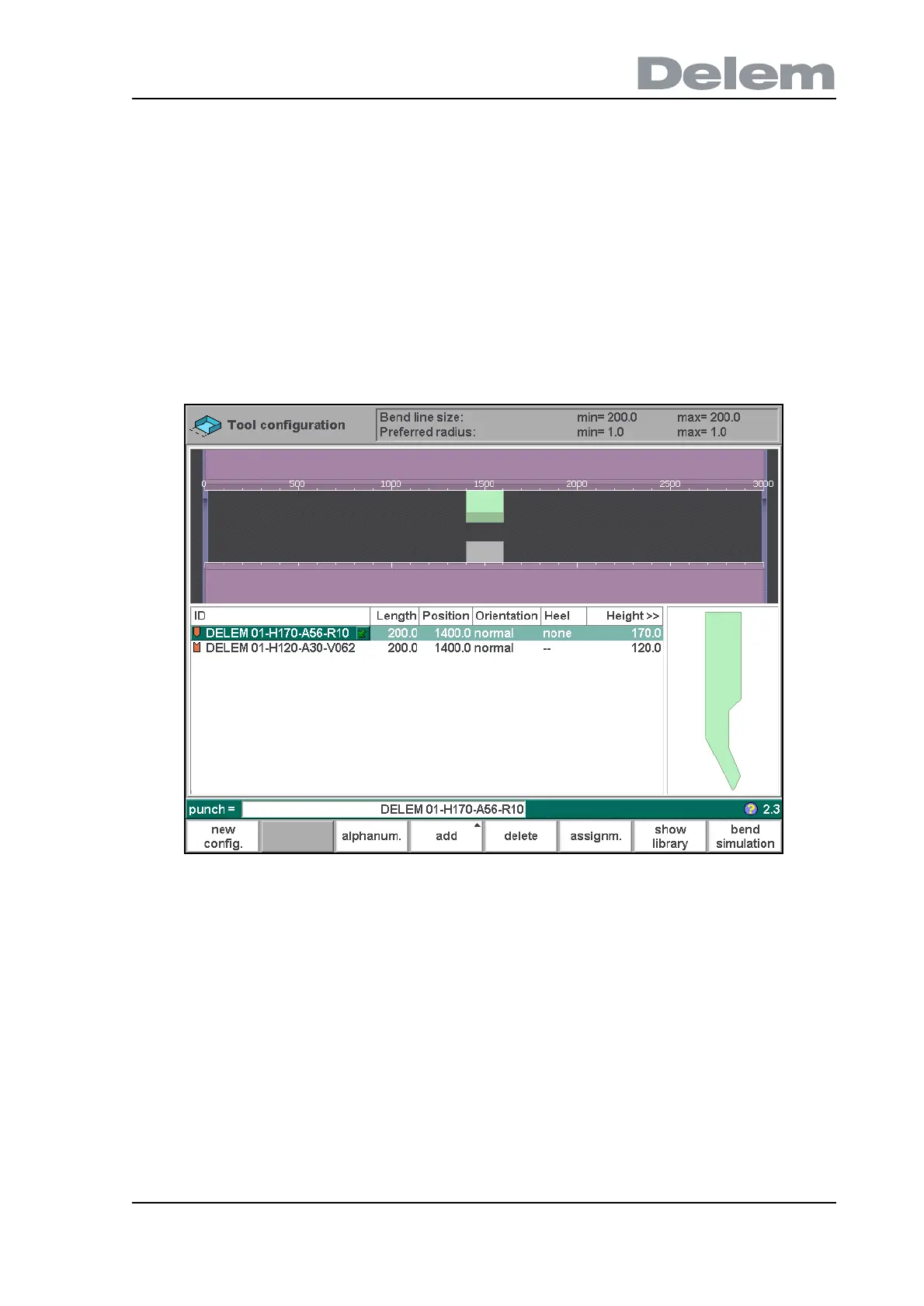

When the function ‘tool configuration’ has been activated, the screen shows a front view of the

machine set-up in the upper half of the screen. In the lower half of the screen, the tool data is

displayed. In this screen, the placement of tools in the machine can be programmed.

3.a

In the front view, the following machine elements are shown, from top to bottom:

• machine upper side (pressing beam);

• adapter for punch (if an adapter is programmed);

• punch;

•die;

• machine lower side (table).

The machine parts have already been pre-selected in the menu ‘program constants’. Normally

these parts will not change. Whether an adapter can be programmed depends on the

parameter ‘enable adapters’ in the programming constants.

When starting a new tool configuration, the machine opening is empty.

Loading...

Loading...