V1108, 3.10

Optimisation degree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .OD

Range 1-5.

The number of alternatives to be computed for each bend must be entered here.

The higher this number the more alternatives are to be examined by the control, so the

longer the computing time will be.

Front extend ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .FR

Range 0.0 - 1.0.

This is the ratio of the minimum allowable length of your product which extends in front

of the press to the total blank length of the product. You must have a minimum length of

your product in front of the press to be able to handle the product.

Front extend ratio accept. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .FA

0 = comply if possible:

This means that when possible the computer tries to comply to the front extend ratio and

only when this will result in no solutions to be found it will accept that the length in front

is smaller than the specified ratio.

1 = comply always:

The computer will always comply to the front extend ratio. This may result in no

solutions to be found.

Press the key to select the required setting.

Radius factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RF

The computed radius of a bend is multiplied by this factor for correction purposes. This

correction affects the X-axis position and the computed blank length. The initial value of

RF is 1.

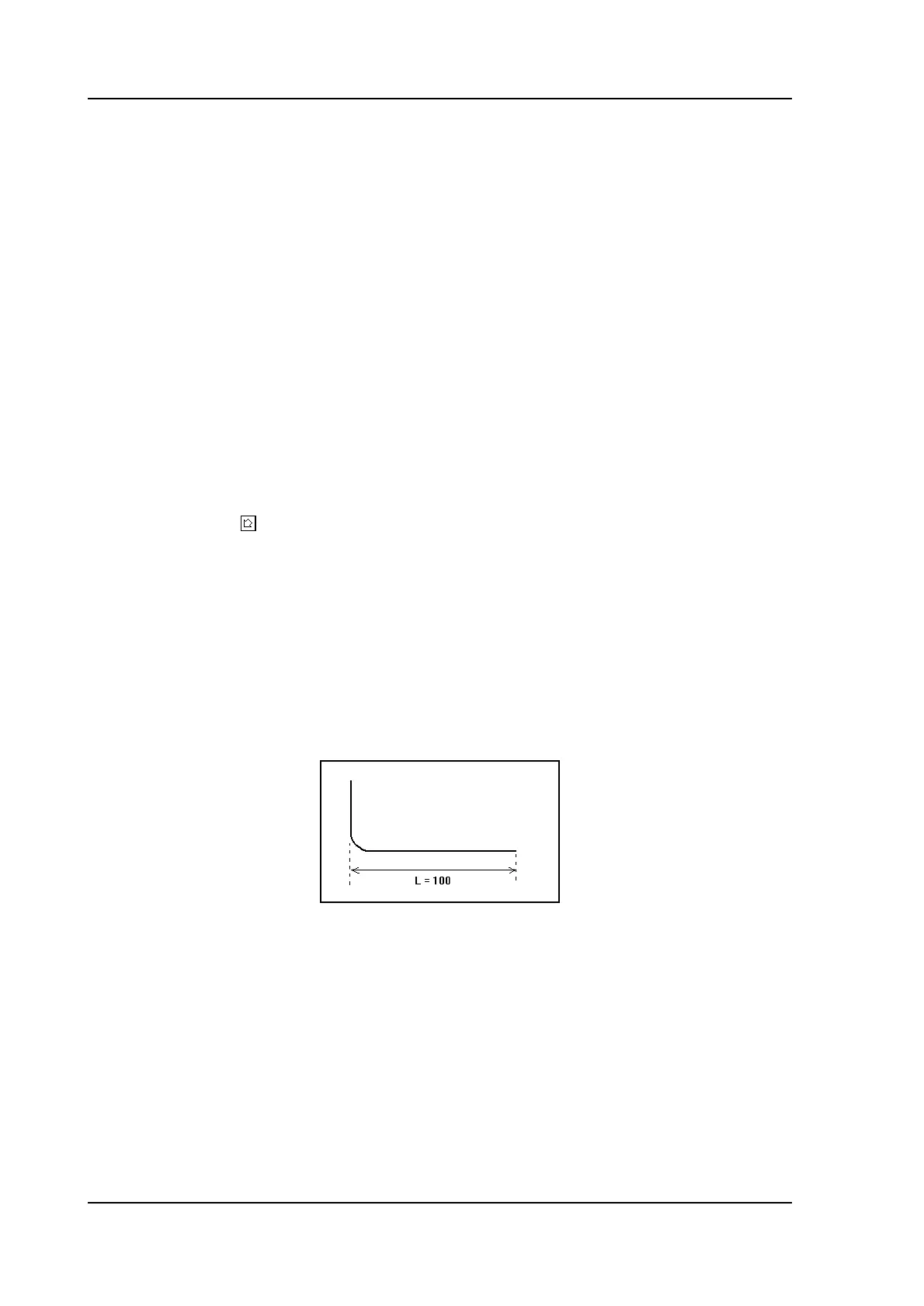

The controller computes the X-axis position necessary to obtain L=100 as shown in figure 3.l.

The accuracy of the length L is dependent on the material parameters like thickness, strength

and kind of material. In order to have a correction possibility with the radius factor RF you can

optimise this computation.

3.l

Punch length tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PT

The punch length may be shorter than the length of the bendline.

The maximum allowed difference between the punch length and bend length can be

programmed here. Punch length tolerance may influence your bend sequence: if the

length of a punch is shorter than the tolerance permits, it will not be accepted for a bend.

See figure below in which the Punch length has been indicated by PL and the bending

length by BL. The tolerance value is the difference between PL and BL.

Loading...

Loading...