V1108, 4.7

Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..BM

Select the required bending method. The control supports 4 methods:

Air bend

Bottoming

Flattening

Flattening & bottoming.

Press the key to select the required setting.

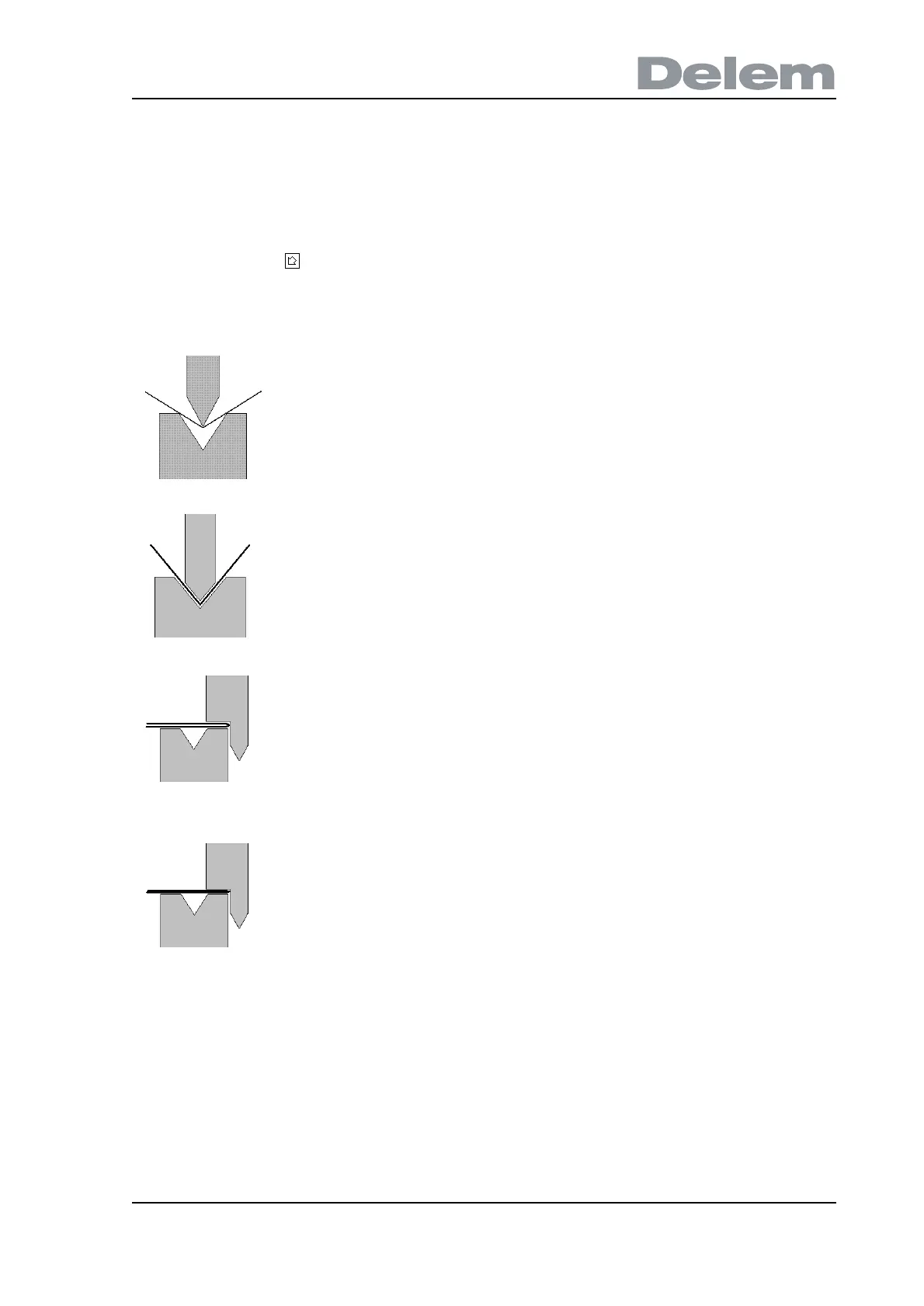

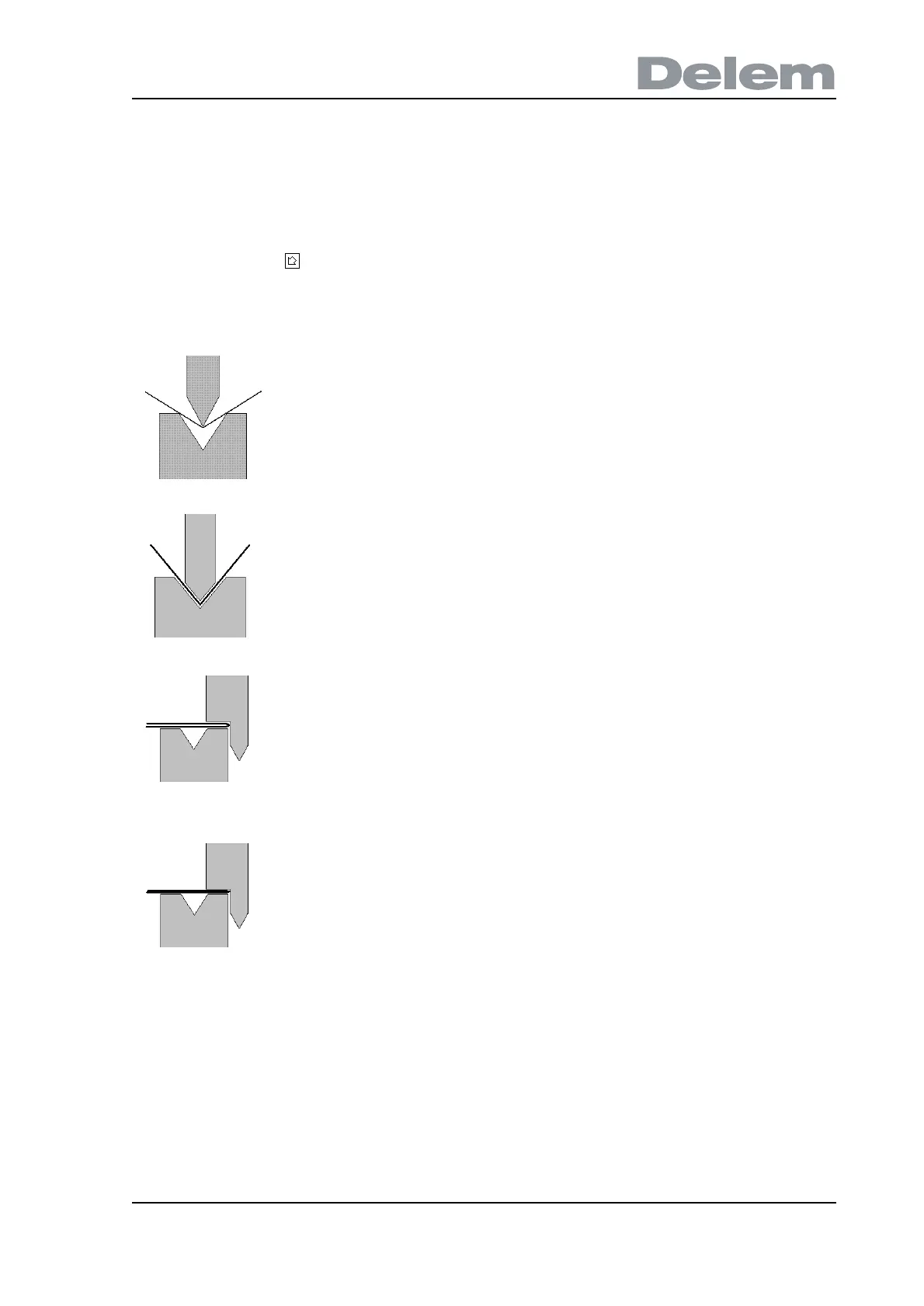

Bend methods:

Note 1:

The flattening bends are shown here with a special flattening punch, but this is not required.

Note 2:

When bottoming operation is selected, the end of bend position of the Y-axis beam depends

on the working force. If however the force is sufficient for the beam to go to the calculated Y-

axis end of bend position, the beam stroke will be limited by the position value.

air bend The sheet is bent to the programmed angle

by bringing the punch to the required depth.

The control calculates the required Y-axis

position to obtain the programmed angle.

bottoming The sheet is bent by squeezing the sheet

between the punch and the die. The control

assumes the bottom of the die as required Y-

axis position.

flattening The sheet is folded in two. This is possible

after the sheet has been bent into a sharp

angle in a previous bend. The control

calculates the precise Y-axis position for this

action: the surface of the die plus twice the

sheet thickness.

Y-axis positioning can be adjusted by

programming a 'flattening offset'.

flattening and

bottoming

The same as flattening, but now the control

assumes the top of the die as required Y-axis

position. The folded sheet is squeezed

between punch and die.

Loading...

Loading...