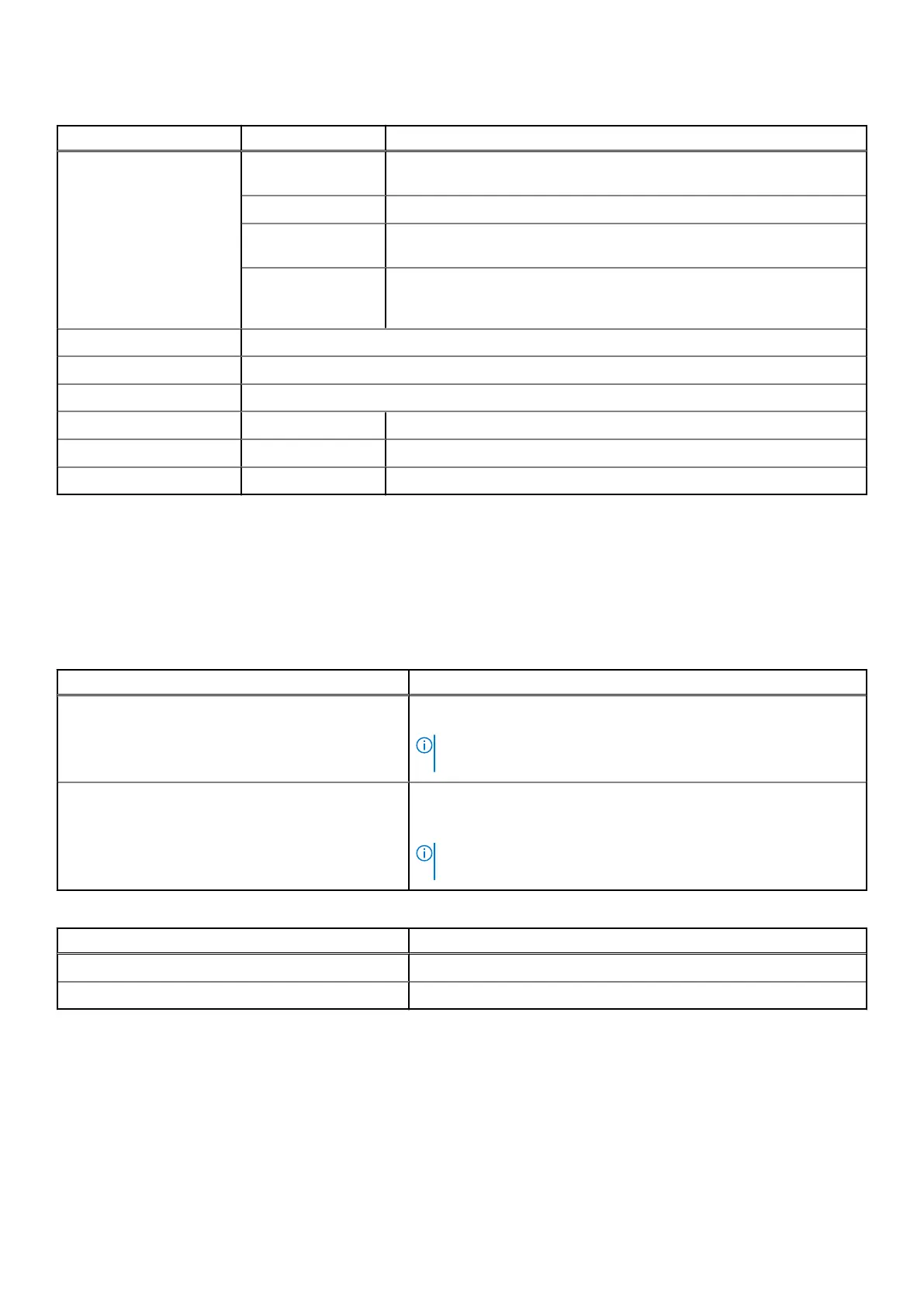

Table 23. Environmental considerations

Industry Configuration Description

Telco GR-1089-CORE Electromagnetic Compatibility and Electrical Safety – Generic Criteria for

Network Telecommunications Equipment

GR-63-CORE NEBS Requirements: Physical Protection

SR-3580 (NEBS

Level 3)

NEBS Criteria Levels

GR-3108-CORE

(Class 1)

Network Equipment in the Outside Plant (OSP). An exception is made for

cold boot at +5C instead of -5C for systems without the Heater Manager

subsystem enabled.

Military N/A

Marine N/A

Power Industry N/A

Safety N/A LDV, IEC/EN, CFR, CSA

EMC N/A EN, CISPR, ES, DTAG, CFR, ICES, VCCI

EMV N/A RoHS, WEEE, EN, ECE

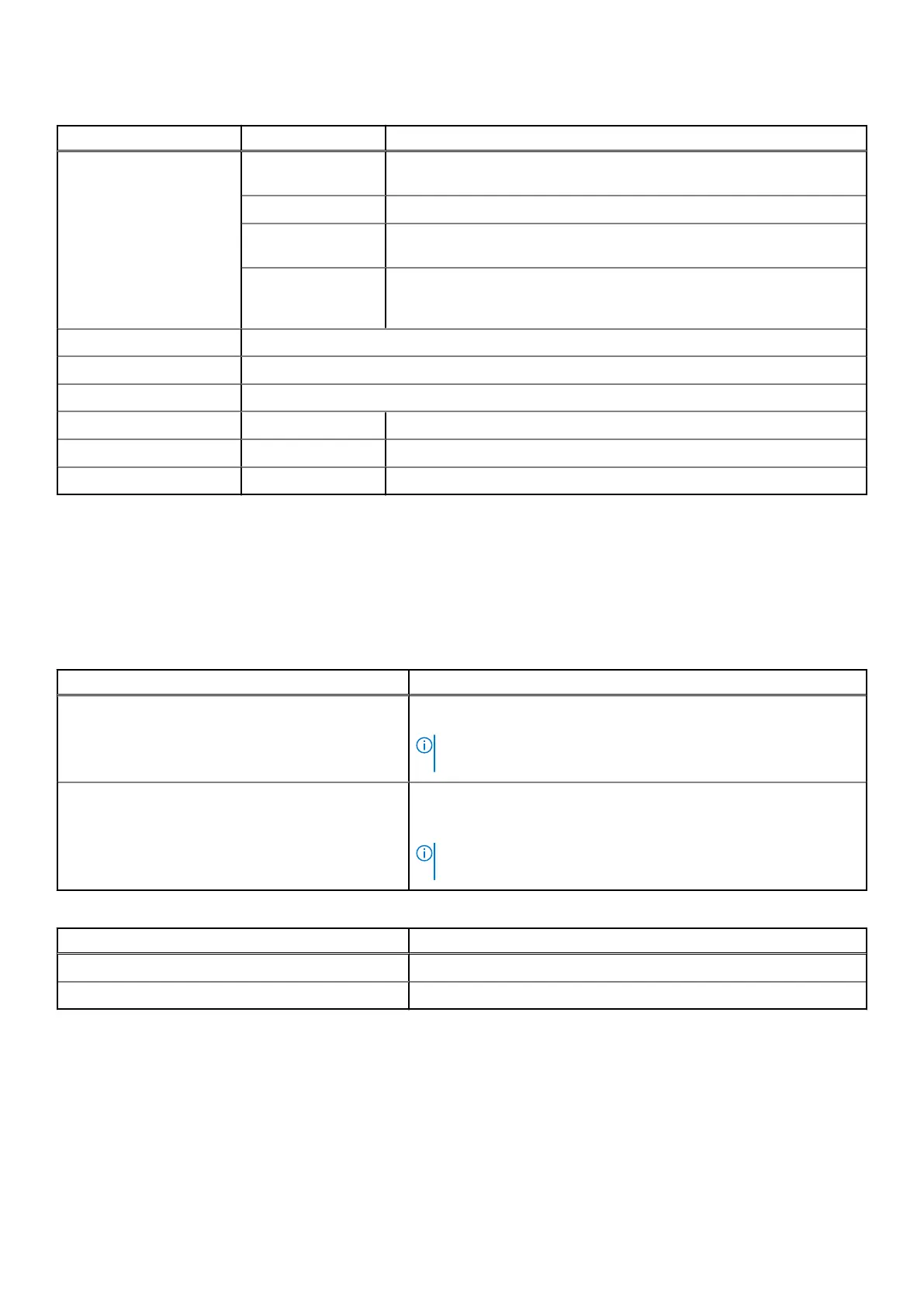

Particulate and gaseous contamination specifications

The following table defines the limitations that help avoid any equipment damage or failure from particulates and gaseous

contamination. If the levels of particulates or gaseous pollution exceed the specified limitations and result in equipment damage

or failure, you may must rectify the environmental conditions. Remediation of environmental conditions is the responsibility of

the customer.

Table 24.

Particulate contamination specifications

Particulate contamination Specifications

Conductive dust Air must be free of conductive dust, zinc whiskers, or other

conductive particles.

NOTE: This condition applies to data center and non-data center

environments.

Corrosive dust

● Air must be free of corrosive dust.

● Residual dust present in the air must have a deliquescent point less

than 60% relative humidity.

NOTE: This condition applies to data center and non-data center

environments.

Table 25. Gaseous contamination specifications

Gaseous contamination Specifications

Copper coupon corrosion rate <300 Å/month per Class G1 as defined by ANSI/ISA71.04-2013

Silver coupon corrosion rate <200 Å/month as defined by ANSI/ISA71.04-2013

Environmental Requirements for installing XR8000

A proper installation of XR8000 protects the system and its components from damage that is caused by external environmental

conditions. So, to ensure normal operation and avoid any unplanned downtime and maintenance activity it is highly imperative

that there is a proper planning and preparation of the site before installing the XR8000 . Also, it is to be noted that the same

site sanity must be maintained during the entire life cycle of the XR8000 server to ensure smooth operations.

General guidelines for maintaining the XR8000:

26

Technical specifications

Loading...

Loading...