Mod. E.T. PEGASUS

D/12

Maintenance and adjustment

- CAUTION: - Read the SAFETY REGULATIONS (in this manual) carefully for the safety of all personnel and the machine.

MAINTENANCE AND ADJUSTMENT SCHEDULE

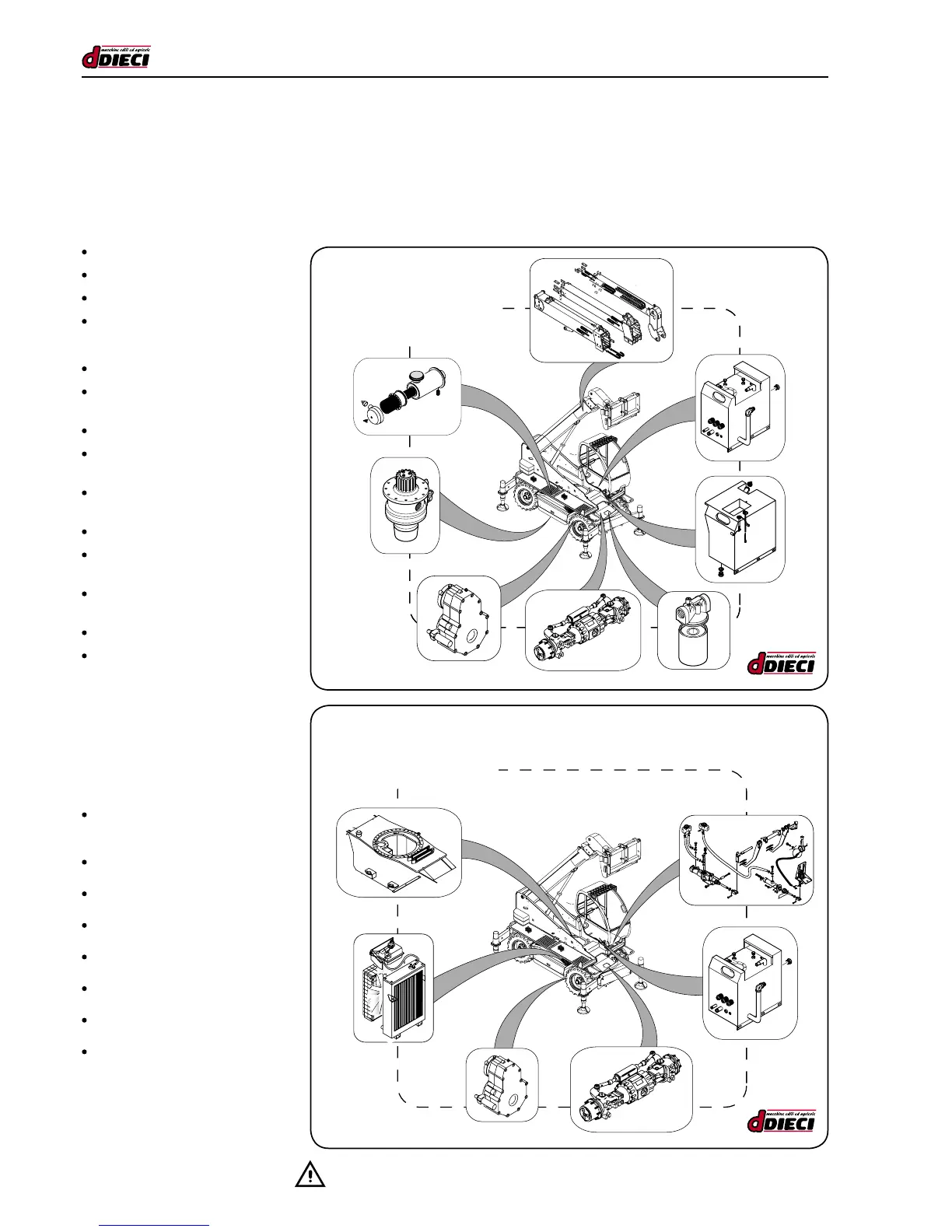

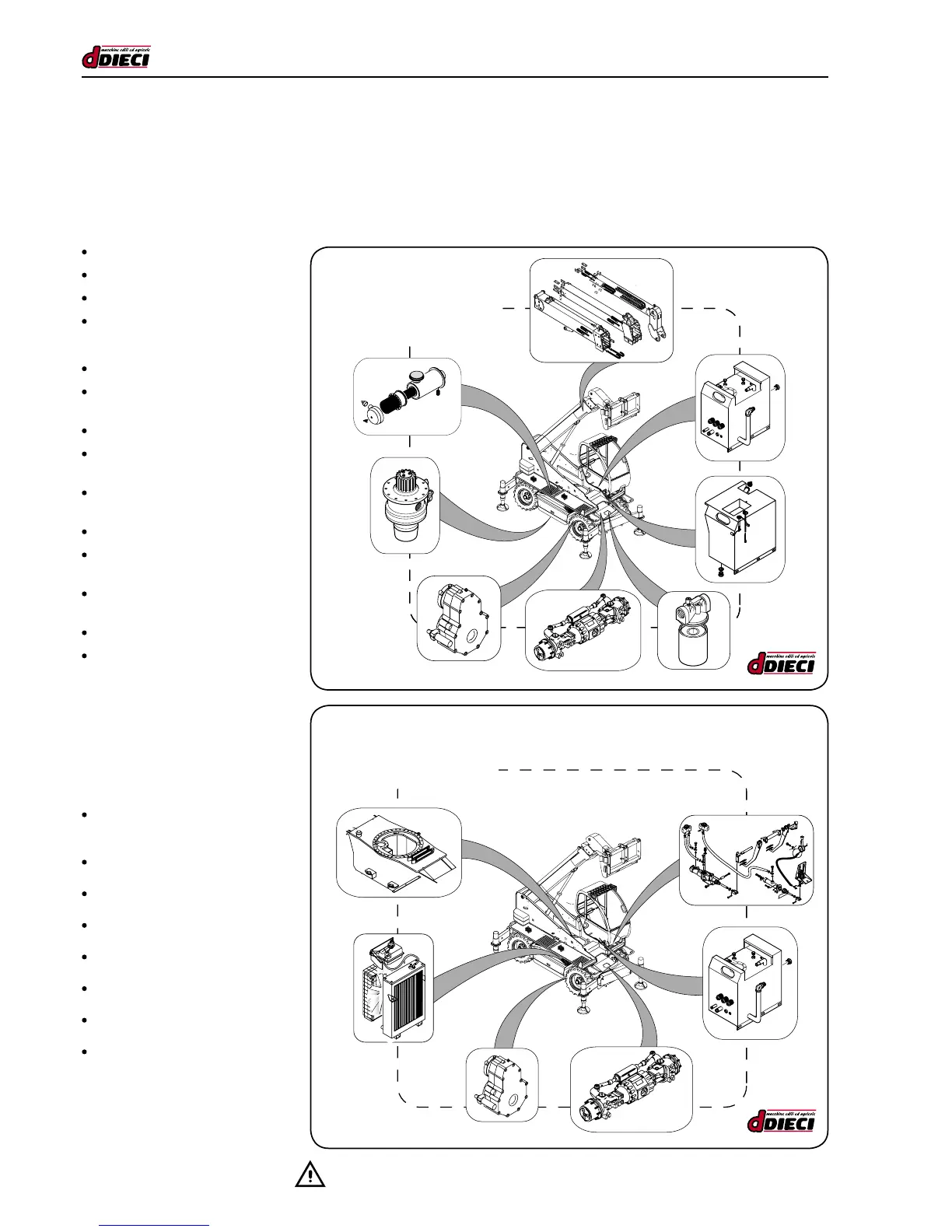

On the left is a list of the maintenance procedures to carry out. The diagrams on the right indicate how often the maintenance has to

be carried out and provide a rough idea of where the parts are located. The asterisk (*) indicates maintenance in case the machine is

used in particular environments.

Every

1000 hours

Every

500 hours

Check tightening torque of

upper and lower swing gear bolts.

Replace coolant.

Replace oil in differential sump.

Replace oil in epicyclic reduction gears.

Replace gear oil.

Replace brake oil.

Replace accelerator oil.

Replace hydraulic system oil.

Replace air lter.

Replace fuel lter.

Drain fuel tank.

Clean pre-lter on diesel injection

pump lter.

Replace hydraulic system oil.

Replace or clean hydraulic oil

system lter.

Replace external hydraulic oil lter.

Check turret rotation reduction

gear oil level

Check epicyclic reduction gear

oil level.

Check gear oil level

Check turret rotation reduction

gear oil level

Check tightening torque of boom

sliding blocks.

Check chain tension.

Replace engine oil lter.

Loading...

Loading...