(g.81/D)

EXTERNAL BOOM CHAINS

(g.81/D)

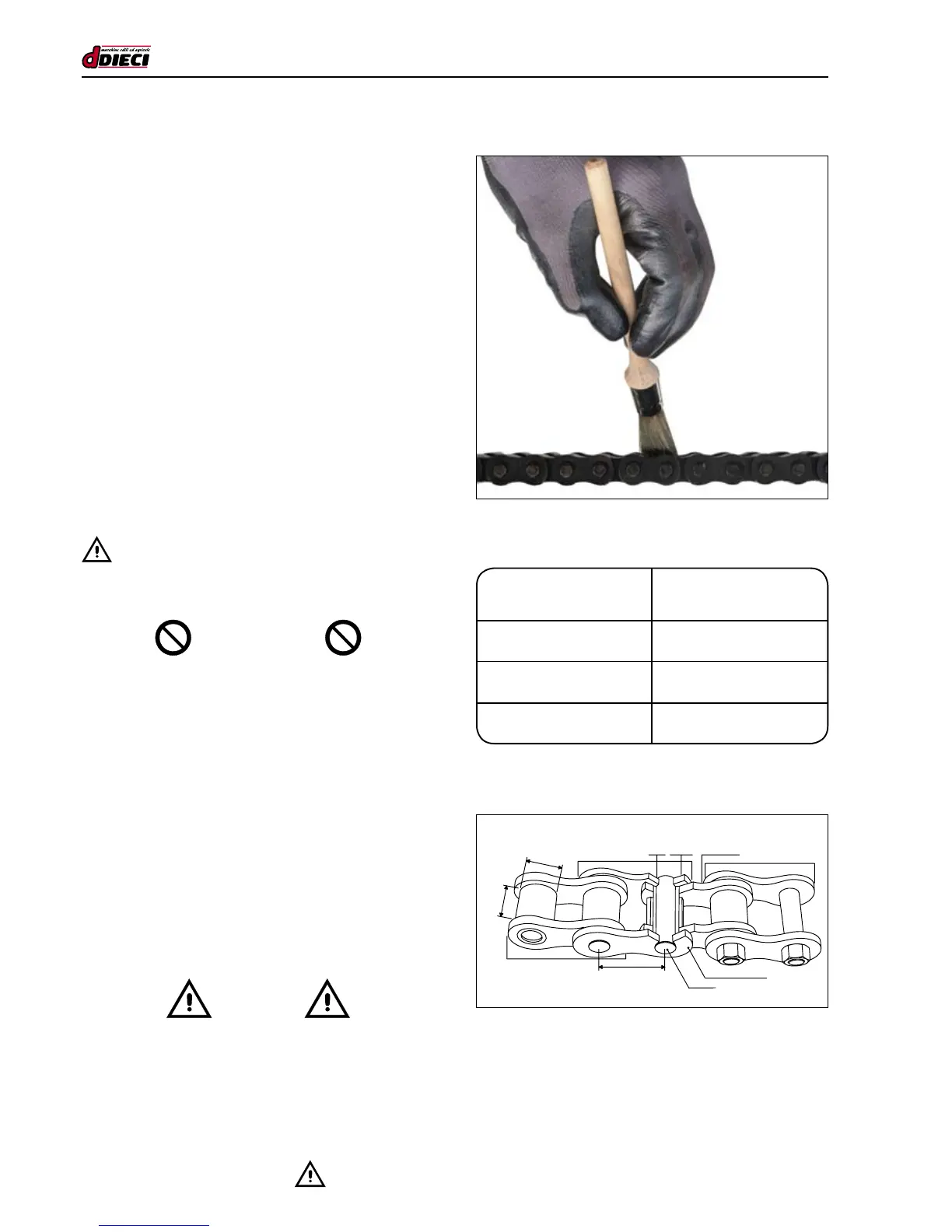

Lubrication

Lubrication means:

- Introducing a liquid between contact surfaces to decrea-

se wear and avoid seizure.

- Protecting the chains against corrosion.

- Reducing the noise produced by contact surfaces.

Lubrication must be carried out:

- Lengthways in an area where the joints are not subjected

to very much stress to ease the penetration of lubricant.

- Transversally between the plates to ease penetration of

the lubricant in the joint.

The viscosity of the lubricant must suit the ambient tempera-

ture. Insufcient viscosity increases lubricant loss, too much

viscosity prevents the lubricant from penetrating the joints.

Consult the table on the right for the correct viscosity (g.82/D).

- CAUTION:

In the case of special applications or use in adverse condi-

tions, consult a DIECI service centre.

- PROHIBITION -

IT IS STRICTLY FORBIDDEN to lubricate

the chains with grease.

Wear inspection

At the prescribed times it is necessary to inspect:

- The installation geometry.

- The condition of the chain, to analyse any traces of fric-

tion that may indicate an incorrect installation geometry.

Wear on the prole of the external plates due to contact

with the pulleys and the drive systems. Wear on the sides

of the external plates and on the heads of the pins due

to contact with the pulley anges or any drive devices.

- Wear on the chain joints either by directly measuring

their length using a measuring tool or control ruler, or by

carrying out a visual inspection.

- Wear of the Flyer hoisting chain plates.

- CAUTION -

The chains must be replaced when wear

due to elongation exceeds 2%.

When chains are replaced, the respective

rollers MUST also be replaced.

Recommended viscosity

ISO VG (Cst)

Temperature (C°)

- 15 < T< 0

0 < T< 50

50 < T< 80

Between 15 and 32

Between 46 and 150

Between 220 and 320

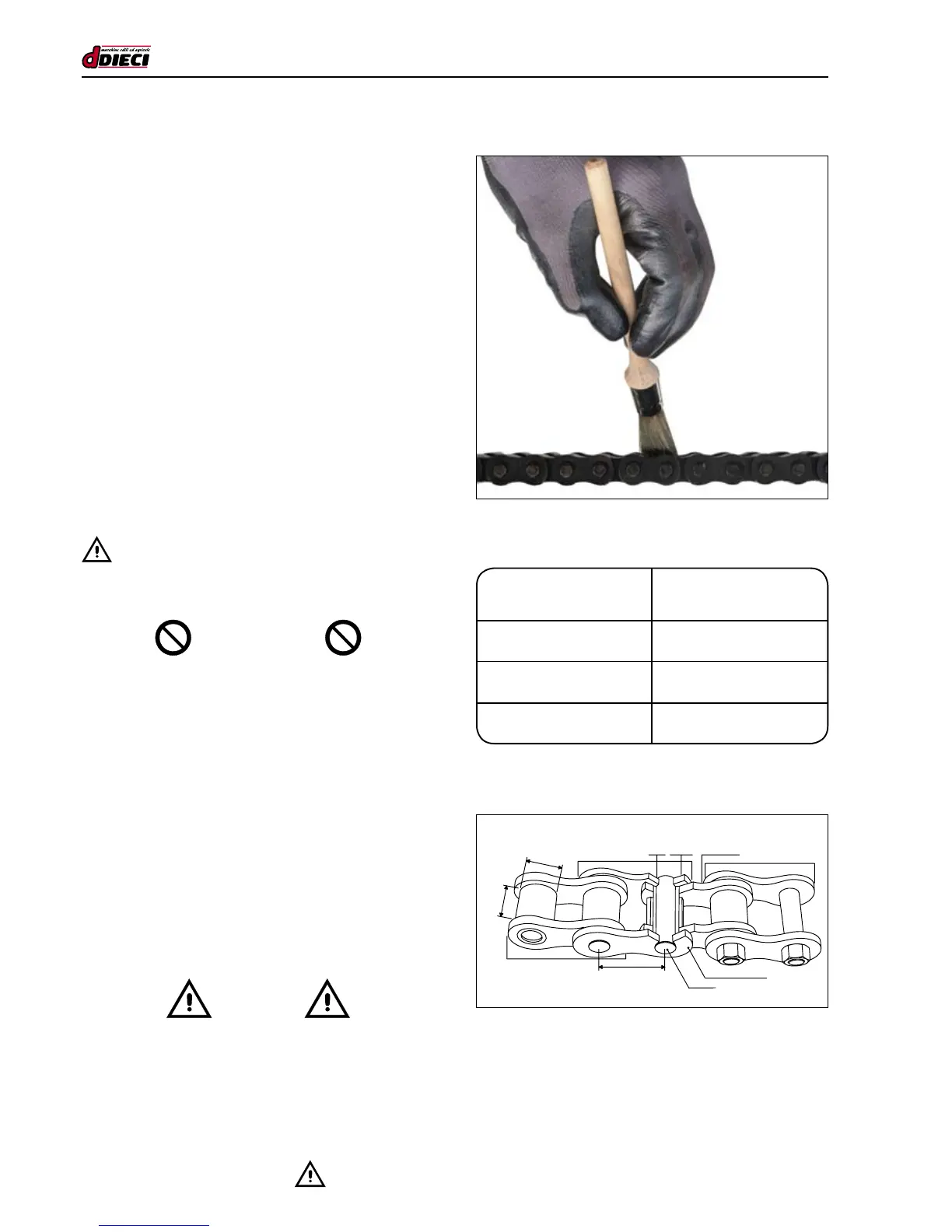

Internal

width

Roller

diameter

External link

Bushing

Roller

Internal plate

Connecting link

External plate

Pin

Pitch

Internal link

(Fig. 82/D) - Chain oil viscosity table

(Fig. 83/D) - Standard chain components

Loading...

Loading...