(g.80/D)

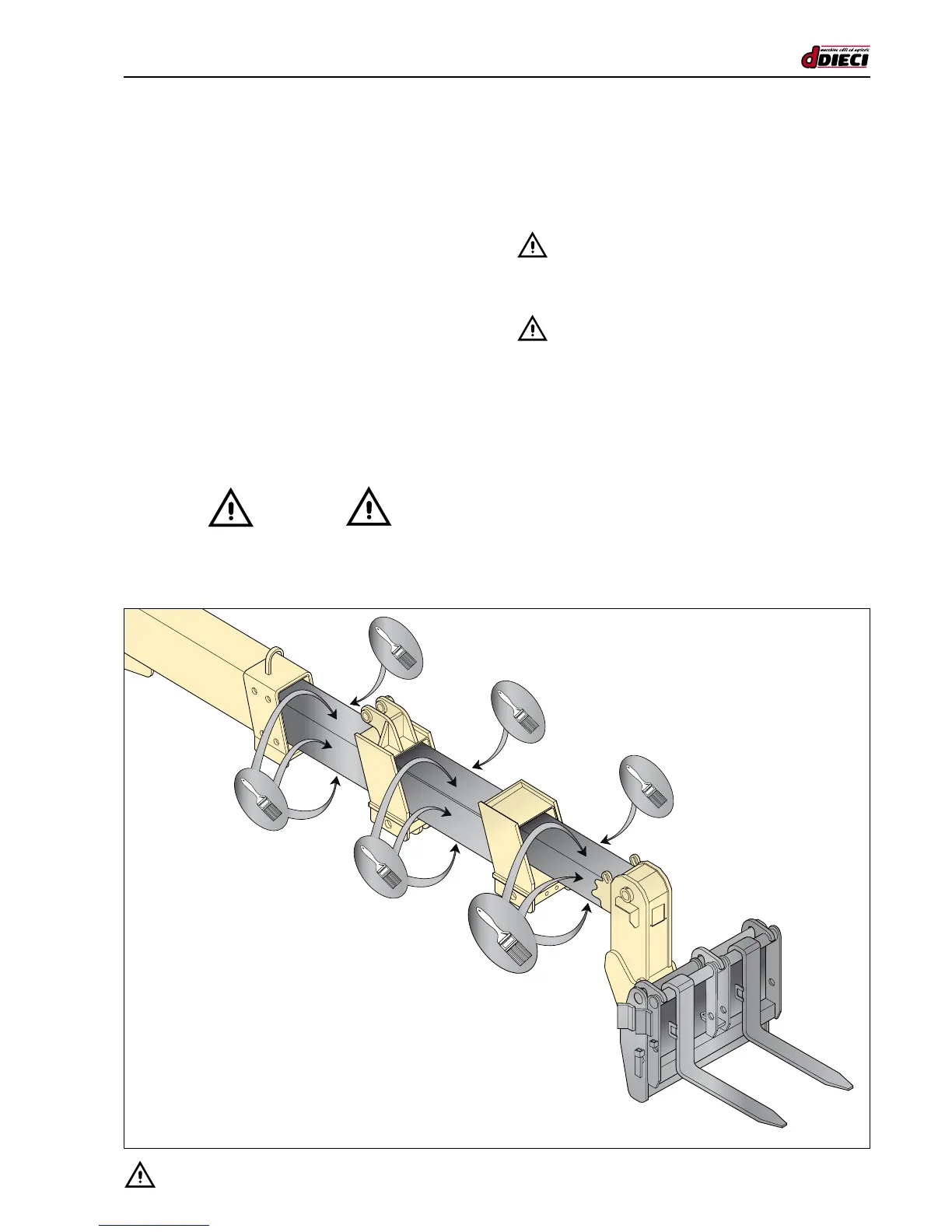

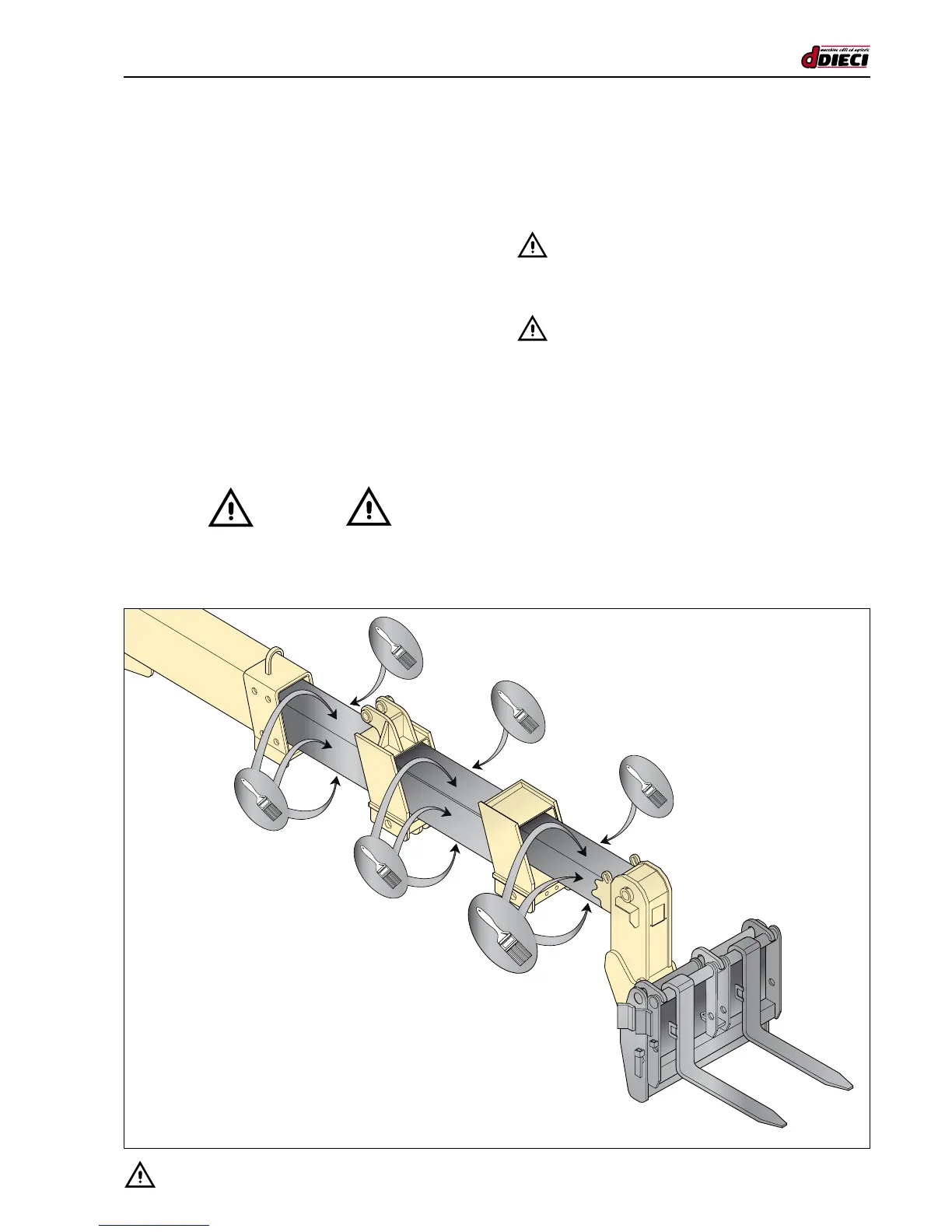

BOOM SLIDING BLOCKS

Lubrication

(g.80/D)

The boom sliding blocks must be kept lubricated to avoid

wear and keep movements smooth.

Completely extend the boom and inspect its surface. If

the layer of lubricant is thin or with impurities (sand, dust,

sawdust, etc.) act as follows:

- While the boom is completely extended horizontally, remo-

ve the layer of lubricant from the extensions with a cloth.

- Use a brush to apply a layer of lubricant of the approved

type on the four sides of the telescopic boom.

- Activate the boom several times to distribute the lubri-

cant evenly.

- Remove any excess lubricant.

- CAUTION -

During the visual inspection and while applying the

lubricant, the machine must be switched off and the key

removed from the cab to avoid accidental manoeuvres.

- CAUTION:

If the machine is used in extreme conditions or in very dusty

environments, lubricate more often.

- CAUTION:

Only use the lubricants indicated in the DIECI tables. Different

lubricants can cause serious damage to the sliding surfaces.

Sliding block wear

Consult the summary table at the start of this chapter to nd

out how often this must be done.

Worn sliding blocks can cause oscillations and bac-

klash between one extension and another with a conse-

quent loss of precision and danger of dropping the load.

The more extreme the working conditions, the greater the

wear. Any maintenance work carried out on the boom sliding

blocks must be carried out by an authorised service centre.

Loading...

Loading...