(g.71/D)

(g.72/D)

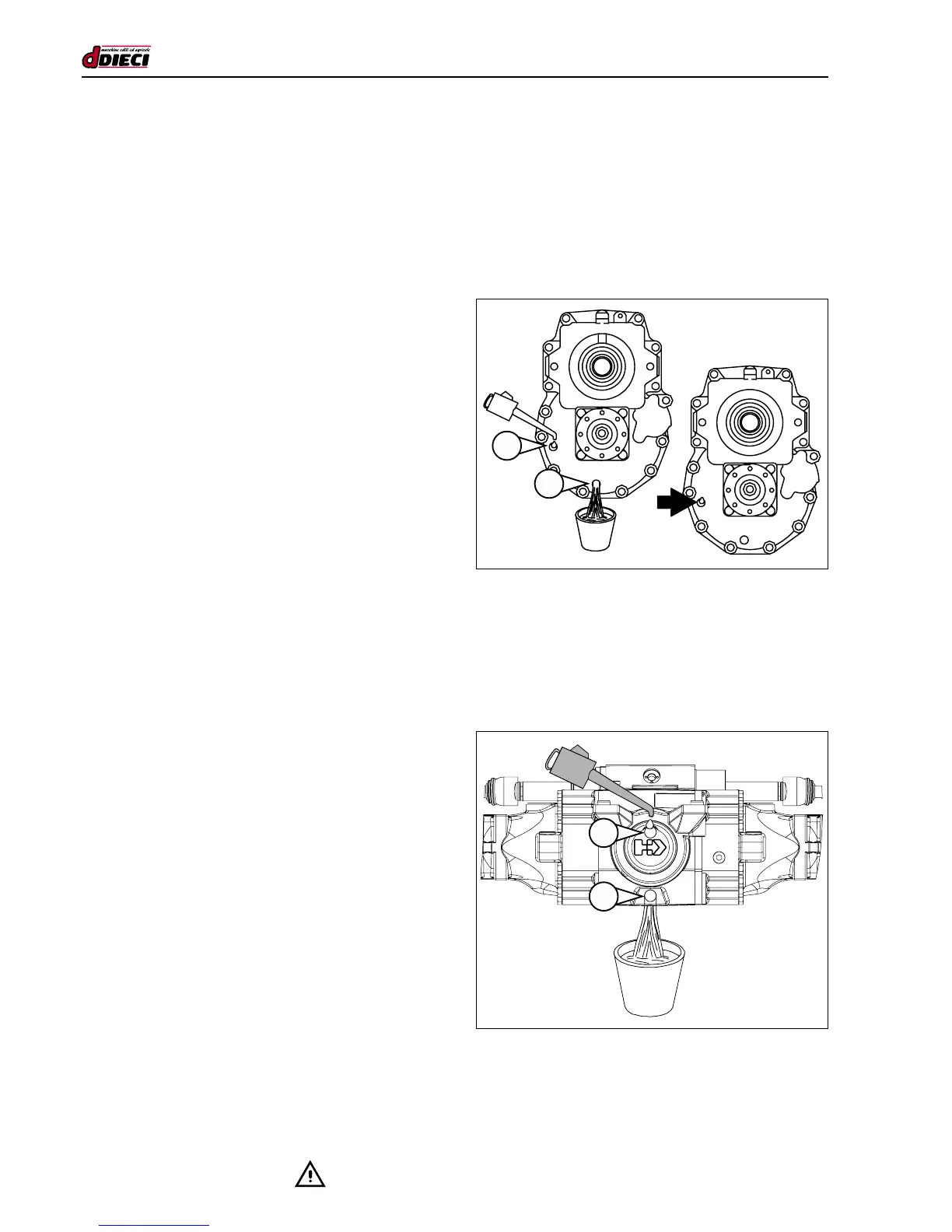

G

F

G

F

REDUCTION GEAR AND DIFFERENTIAL AXLES

The gures are indicative and may not be the same as the

parts assembled on your machine.

The references to maintenance holes refer to the following

pages, which illustrate two standard axles with reduction

gear for more exact identication.

Reduction gear

Changing the oil

(Fig.71/D)

1. Place the machine on a at and level surface while the

differential oil is still hot.

2. Switch off the engine and remove the ignition key.

Place a “maintenance work in progress” sign in the cab.

3. Place a container below the drain caps to collect the

exhausted oil during the replacement procedure.

4. Remove the drain plug (g.71/D Pos. “G”) and the ller/

level cap (g. 71/D Pos. “F”) to drain all the oil completely.

5. Allow the oil to drain away completely.

6. Replace the drain plugs and tighten well.

7. Pour clean oil of the approved type through the ller/level

cap (g.71/D Pos. “F”).

8. The level is correct when oil flows out of the filler/level

cap (g.71/D Pos. “F”).

9. Check for any leaks from the drain caps.

10. Reassemble the filler/level cap and tighten securely.

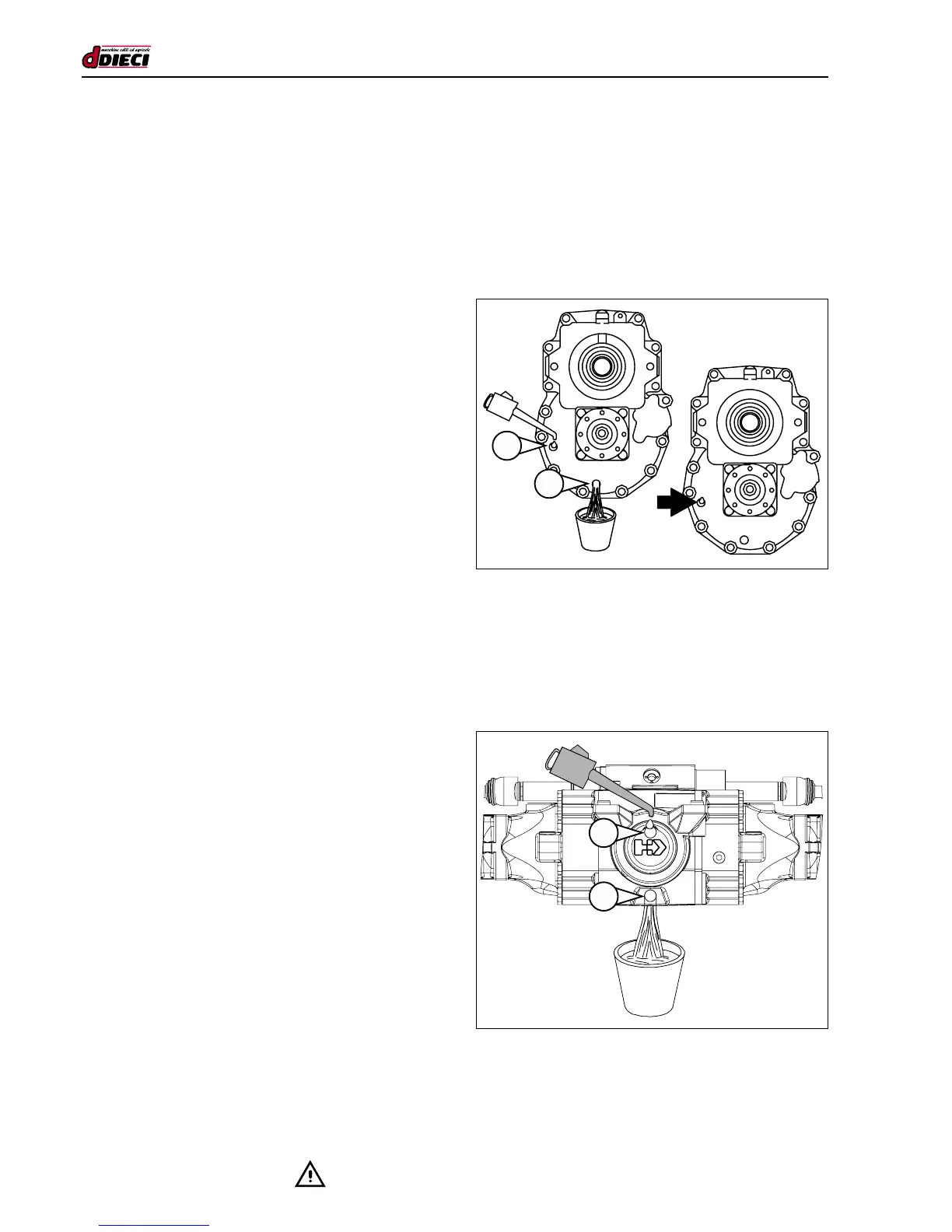

Front/rear differential axles

Changing the oil

(Fig.72/D)

1. Place the machine on a at and level surface while the

differential oil is still hot.

2. Switch off the engine and remove the ignition key.

Place a “maintenance work in progress” sign in the cab.

3. Place a container below the drain caps to collect the

exhausted oil during the replacement procedure.

4. Remove the drain plug (g.72/D Pos. “G”) and the ller/

level cap (g.72/D Pos. “F”) to drain all the oil completely.

5. Allow the oil to drain away completely.

6. Replace the drain plugs and tighten well.

7. Pour clean oil of the approved type through the ller/level

cap (g.72/D Pos. “F”).

8. The level is correct when oil flows out of the filler/level

cap (g.72/D Pos. “F”).

9. Check for any leaks from the drain caps.

10. Reassemble the ller/level cap and tighten securely.

Loading...

Loading...