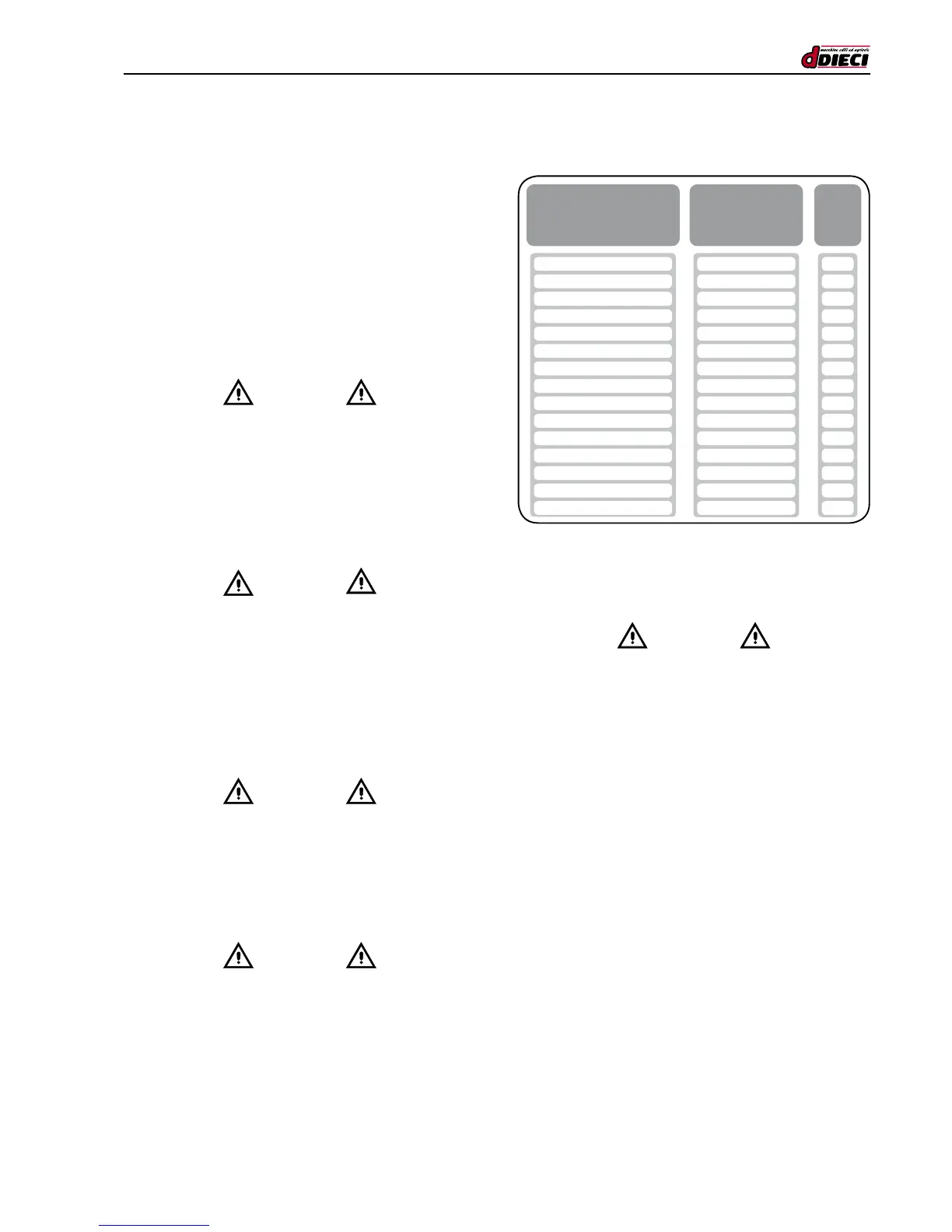

Tyre pressure table

MISURA PNEUMAT ICO

TYRES DIMENSIONS

DIMENSION DES PNEUS

DIMENSION DE LOS NEUMATICOS

REIFENMASS

CARATTERISTICHE

DETA ILS

CARATTERISTIQUES

CARACTERISTICAS

EIGENSHAFTEN

BAR

12,5-18 12PR 3,0

12,5-20 12PR 3,5

18-19,5 16PR 4,5

16/70-20 14PR 3,5

18-22,5 16PR 4,5

405/70-20 (16/70-20) 14PR 3,5

405/70R20 (16/70R20) 152J 6,0

405/70-24 (16/70-24)14PR 4,0

405/70R24 (16/70R24) 152J 5,0

445/65-22,5 (18-22,5) 163A8 (16PR) 4,5

445/65R22,5 168A88,5

445/65R22,5 169F 8,0

14.00-24 16PR 3,75

12,5 -18 10PR 3,0

10,5-18 10PR 3,75

- Check the size of the tyres installed and the ply number

to ensure they are inated to the correct pressure.

- To ensure maximum efficiency do not use tyres with

more than 80% wear.

- CAUTION -

Inating or working on the tyres can be dangerous.

Whenever possible, specialised personnel must be emplo-

yed to work on or install tyres. In any case, to avoid serious

or fatal injuries, comply with the safety measures below.

- The wheels of the machine are very heavy. Handle with

care and ensure that, once warehoused, they cannot fall

and injure anyone.

- Never attempt to repair a tyre on a public road or motorway.

- Ensure the jack is positioned on a solid and at surface.

- Ensure the load capacity of the jack is suitable for rai-

sing the machine.

- Use stands with jacks or other blocking devices to sup-

port the machine while the tyres are being repaired.

- Never place any part of your body below the machine.

- Never start the engine while the machine is supported

by the jack.

- Never hit the tyres or rims with a hammer.

- Ensure the rim is clean, rust-free and undamaged. Do not

weld, braze or repair in any way or use a damaged rim.

- Do not inate tyres unless the rim is assembled on the

machine or secured so that it cannot move if the tyre or

rim suddenly breaks.

TIGHTENING THE WHEEL NUTS

- Tighten the wheel nuts as indicated in the maintenance table.

- The tightening torque of the wheel nuts is as follows:

18 diameter wheel stud bolt 50 kgm

22 diameter wheel stud bolt 60 kgm

- Always tighten opposite nuts, never tighten nuts conse-

cutively.

- After reassembling the wheel, tighten the nuts between

the wheel and axle. Then check the nuts every day until

the tightening torque has stabilised.

- CAUTION -

THE NUMBER OF AXLE STUD BOLTS MUST CORRESPOND

TO THE NUMBER OF TIGHTENED NUTS.

THEREFORE, EVERY NUT ON EVERY WHEEL MUST BE

ASSEMBLED; OTHERWISE THE MACHINE WILL NOT WORK.

- If a wheel on the machine is changed, the wheel or

raised side of the machine may only be lowered on the

ground after the wheels have been assembled and cor-

rectly tightened.

- CAUTION -

THE NUTS MUST BE TIGHTENED BEFOREHAND WHILE

THE MACHINE (OR PART OF THE MACHINE) IS RAISED

OFF THE GROUND AND THEN WHILE THE MACHINE IS

STANDING ON THE GROUND.

- Only use original DIECI nuts to tighten the wheels. If you

lose even just one nut, contact a DIECI service centre.

TYRES

- CAUTION -

WHEN YOU RECEIVE THE MACHINE, CHECK THE AIR

PRESSURE OF THE TYRES.

- Check tyre pressure every 100 hours or every two

weeks. Check the pressure when the tyres are cold.

- Every time the machine is used, ensure the sides of the

tyres are not damaged.

- CAUTION -

TYRES WITH ANY CUTS OR THAT ARE EXCESSIVELY

WORN MUST BE REPLACED IMMEDIATELY.

- Keep any oil, grease and corrosive liquids well away

from the tyres to prevent damage to the rubber.

- The tyre pressure must be kept at the level indicated

in the table below.The tyre pressures given correspond

to the manufacturer’s recommendations, and therefore

must be complied with as far as possible.

Loading...

Loading...