1

1

1

3

4

2

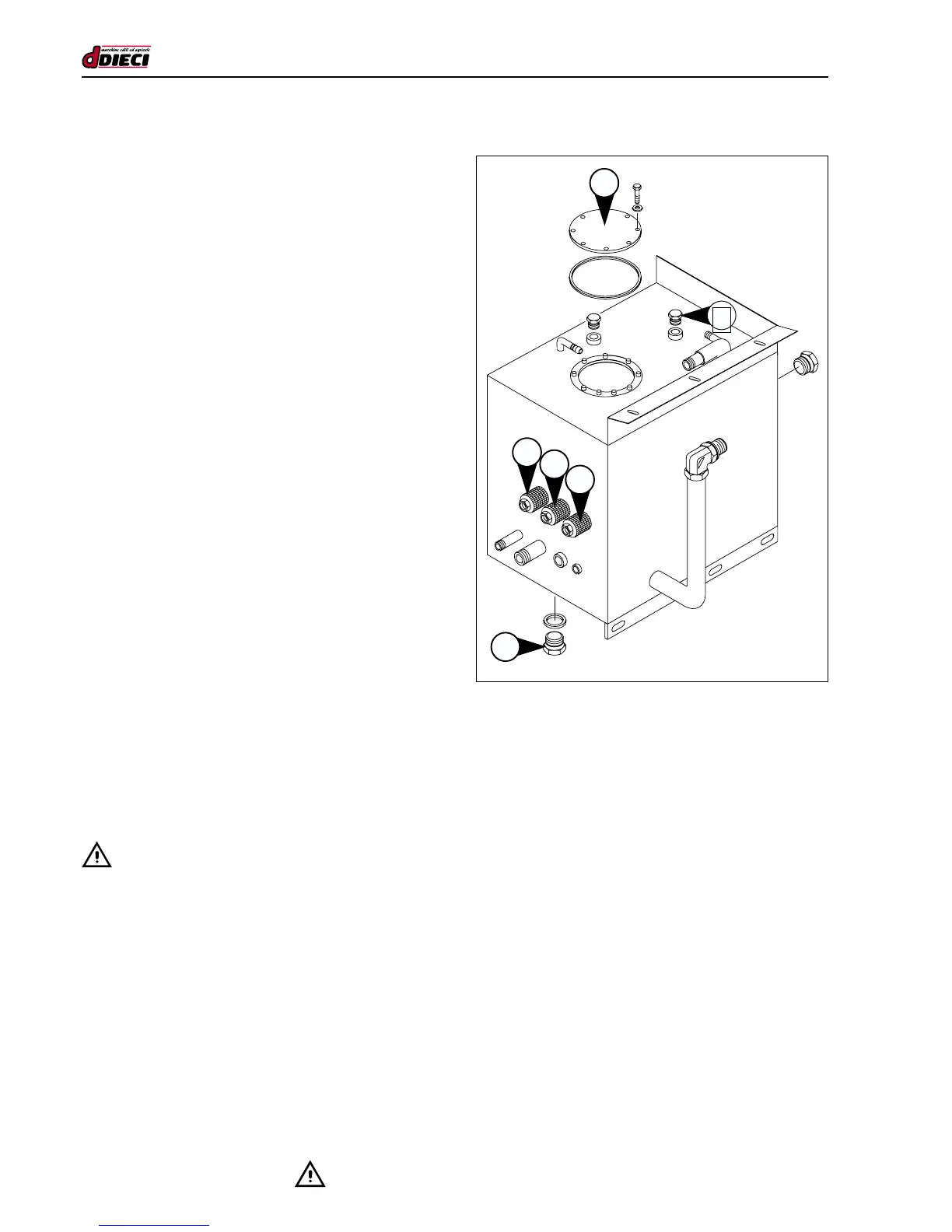

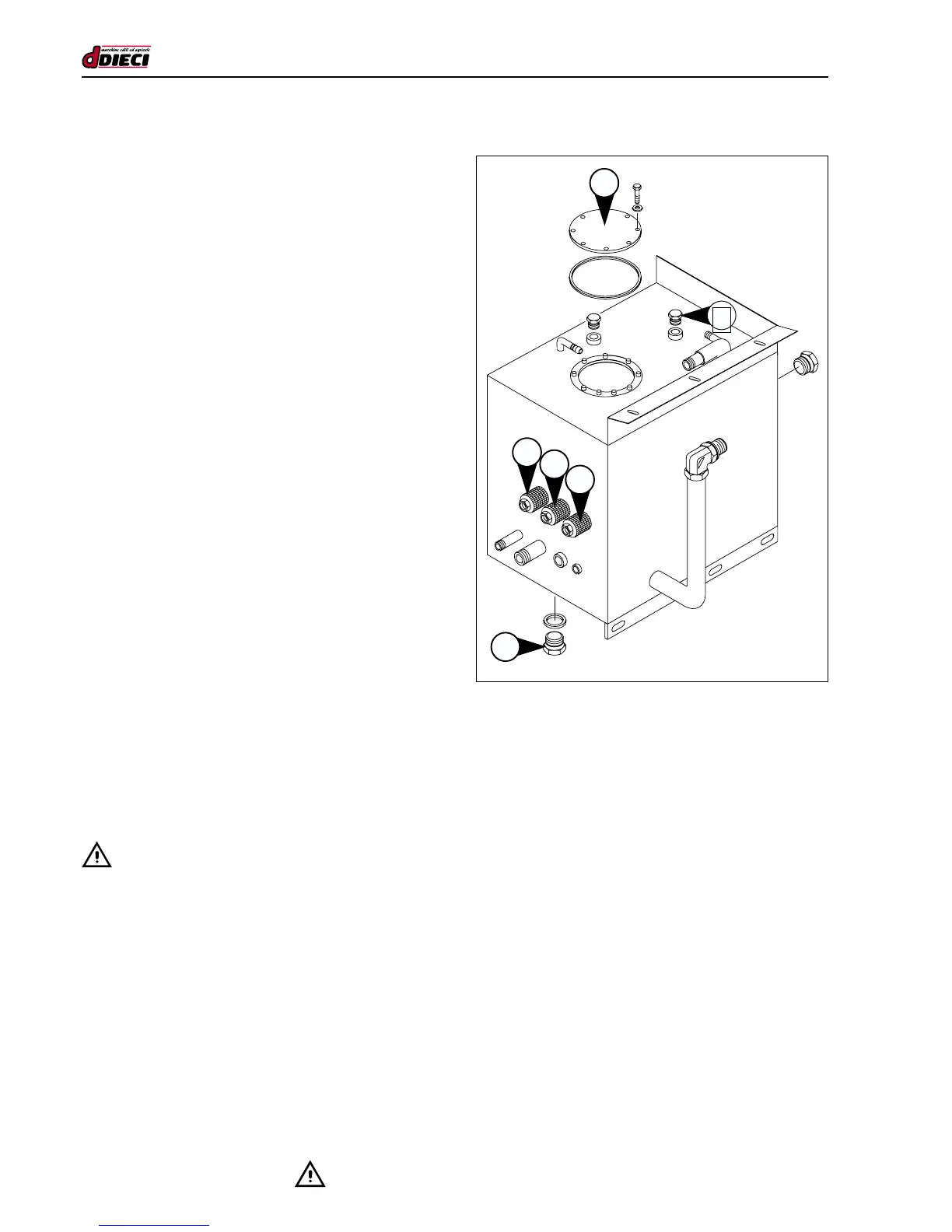

(g.18/D)

Changing the hydraulic oil and lters

Consult the summary Table at the start of this chapter to nd

out how often this must be done (pages D/9-10-11)

There are three mesh lters inside the tank (g.18/D Pos.“1”)

which avoid the issue of any dangerous particles in the

hydraulic system.

Replacement of the hydraulic oil, the lters inside the tank and

the hydrostatic lter must always be carried out in succession.

It is not possible to intervene on just one of the components.

To change the oil and lters correctly:

- Place the machine on level ground.

- Retract and lower the entire boom and position the cylin-

ders in transportation mode.

- Switch off the engine and remove the ignition key.

Place a “maintenance work in progress” sign in the cab.

- Place an adequately sized container below the drain plug.

- Remove the drain plug (g.18/D Pos.“2”) to drain the oil. Re-

move the ller cap (g.18/D Pos.“3”) to speed up the operation.

- When the tank is completely empty, remove the flange

(g.18/D Pos.“4”) by unscrewing the bolts and thus pro-

viding access inside.

- Unscrew the filters (fig.18/D Pos.“1”) inside the tank

using a fork spanner.

- Insert the new lters and tighten with the fork spanner.

- Reposition the flange (fig.18/D Pos.“4”) in its housing

and tighten the bolts.

- Reinsert the drain plug (g.18/D Pos.“2”).

- Fill the tank to the correct level through the filler cap

(g.18/D Pos.“3”).

- Start the machine and move the hydraulic cylinders to

release any air bubbles.

- Re-check the hydraulic oil level and top up if necessary.

- CAUTION:

Exhausted oil is a potential danger to the environment

and must be disposed of appropriately.

Loading...

Loading...