1

3

2

(g.33/C)

(g.34/C)

1

B

A

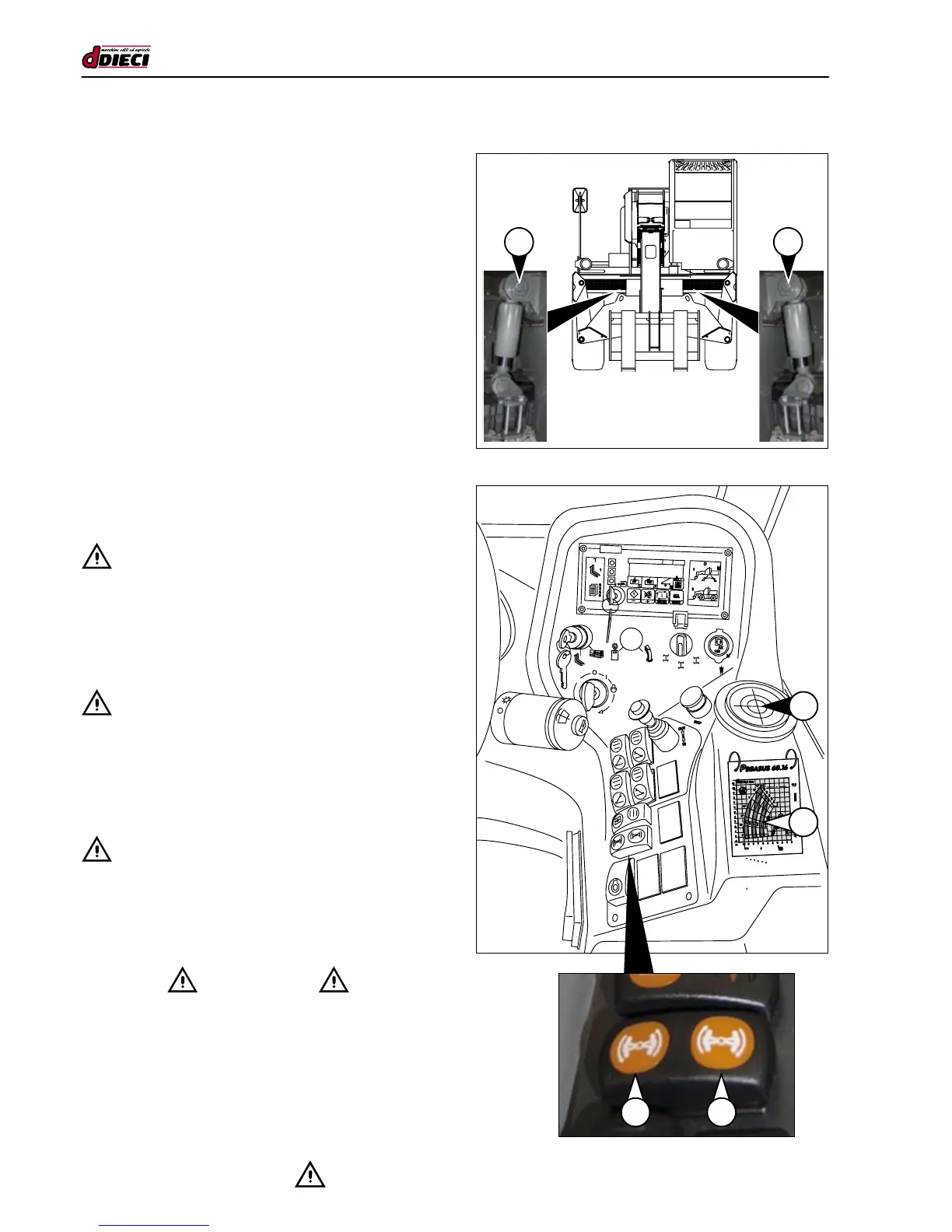

LEVELLING THE FRONT DIFFERENTIAL AXLE

(g.33/C Pos.“1”)

The machine must always be levelled. Failure to level the ma-

chine can cause the load to drop or the machine to roll-over.

Using the front differential axle levelling device, it is

possible to align the machine with the horizontal work surface.

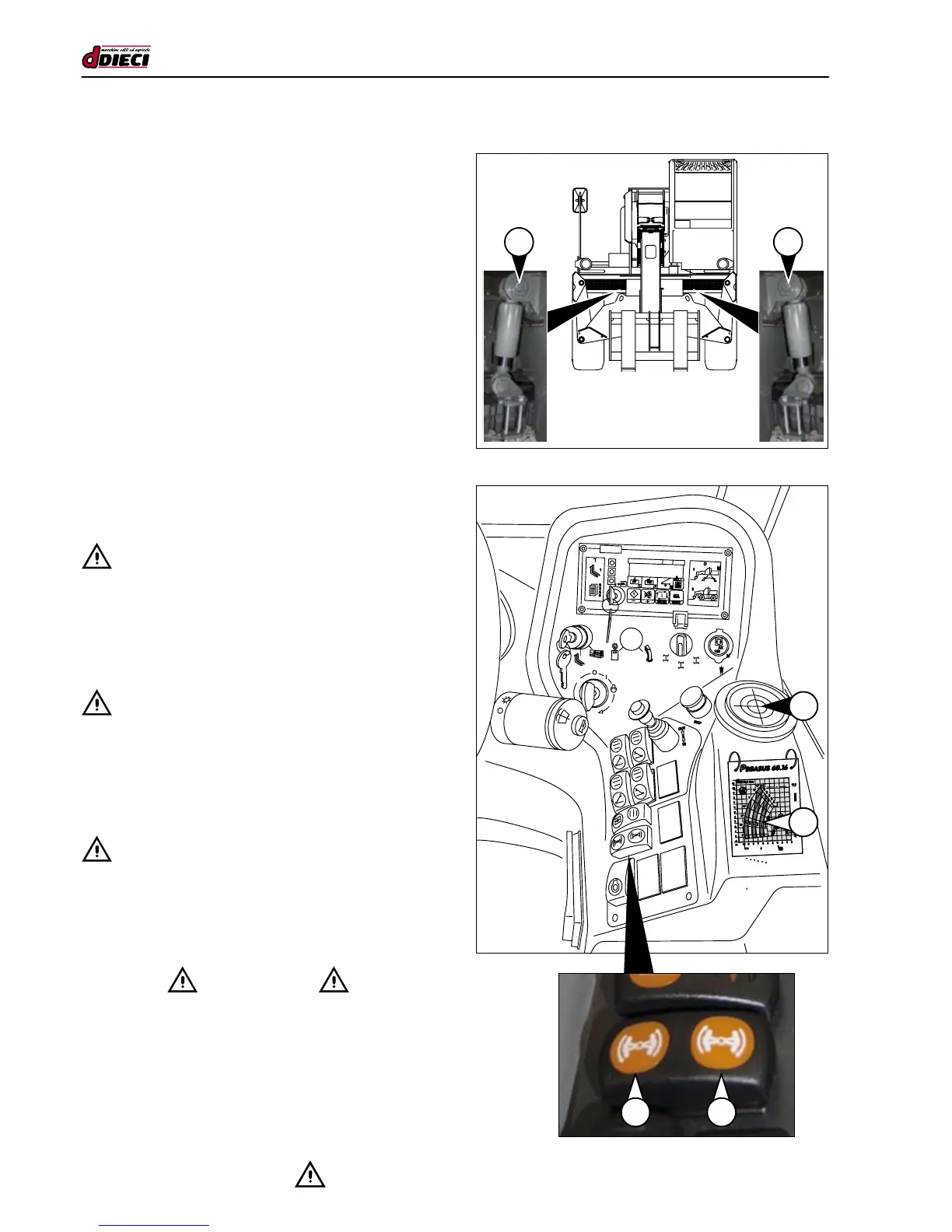

Always ensure that the machine is levelled correctly by

using the spirit level in the cab (g.34/C Pos.“2”).

The correct levelling sequence is as follows:

1. Place any loads on the ground.

2. Completely retract and lower the telescopic boom.

3. Align the turret with the lower chassis.

4. Lock rotation with the locking pin.

5. Level the machine by acting on the relative switch.

- Press part “A” of the selector to level the machine to-

wards the left (g.34/C).

- Press part “B” of the selector to level the machine to-

wards the right (g.34/C).

- CAUTION:

To ensure you are working in complete safety, the machine

must be levelled. The maximum allowed tilt is 2°.

Once the machine has been levelled correctly, continually

ensure it stays levelled by checking the spirit level in the cab

(g.34/C Pos.“2”).

- CAUTION:

The levelling device can only be used when the turret is

aligned with the lower chassis and when rotation is blocked.

When the rear differential axle lock is enabled, it is also pos-

sible to work without stabilisers.

Check the specications in the load tables (g.34/C Pos.“3”).

- CAUTION:

Before operating the machine, the operator must lock the

rear axle by acting on the relative switch.

The rear axle oscillation lock must be enabled when the ma-

chine is used without stabilisers.

- ATTENTION -

THE LEVELLING OF THE FRONT DIFFERENTIAL AXLE

IS NOT PRESENT ON THE PEGASUS 38.16

Loading...

Loading...