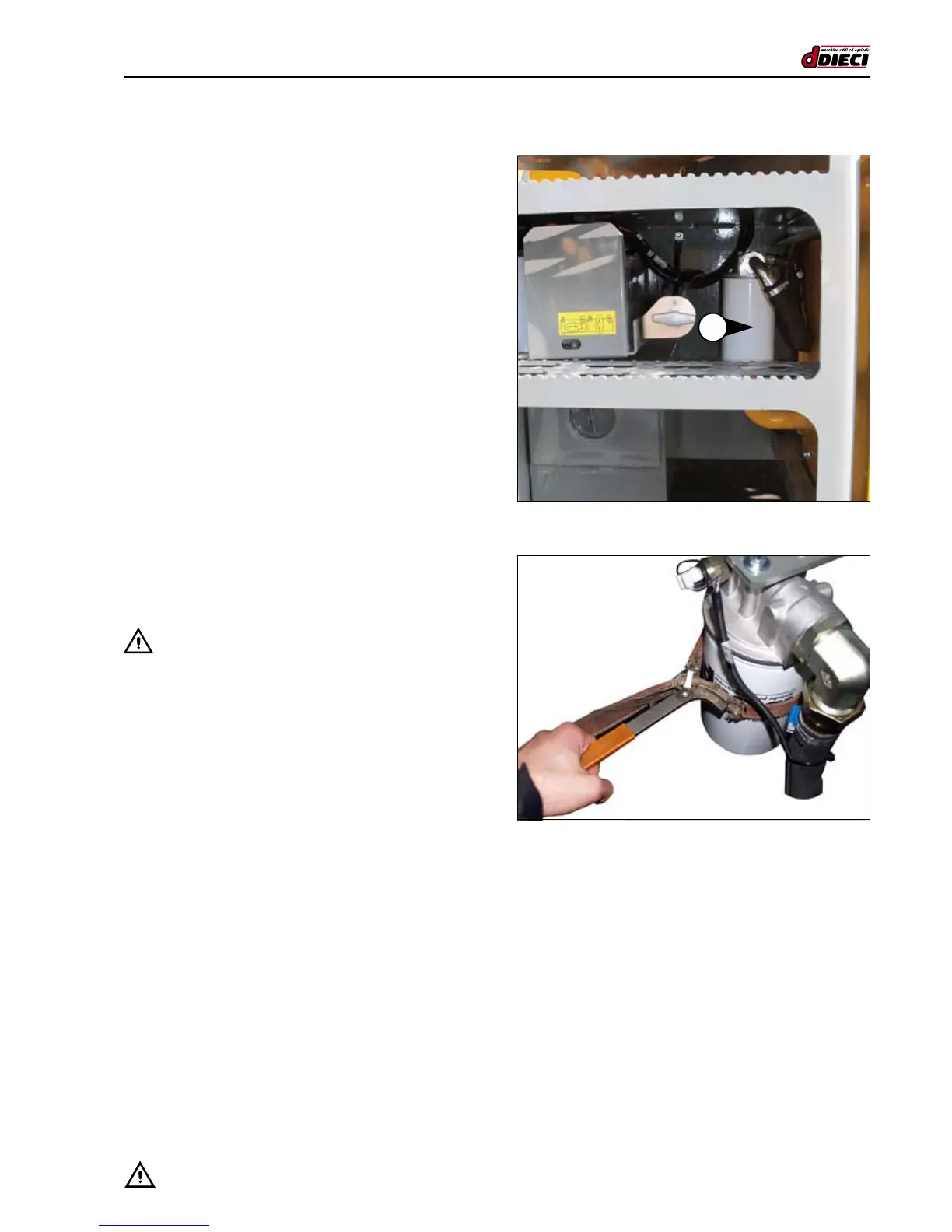

(g.19/D)

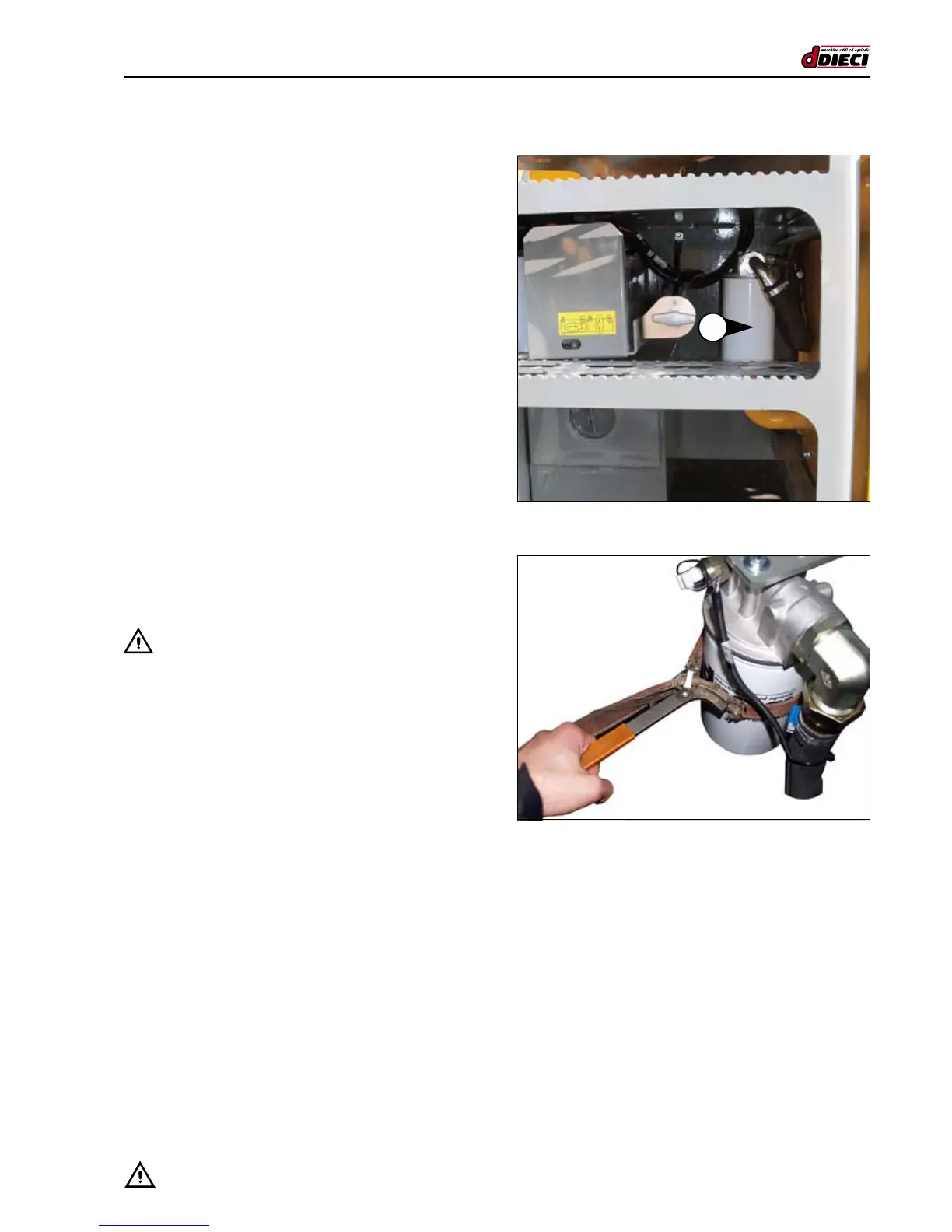

(g.20/D)

1

Hydrostatic system lter

(Fig.19/D Pos.“1”)

To replace correctly, proceed as follows:

1. Park the machine on a level surface.

2. Retract and lower the entire boom and position the cylin-

ders in transportation mode.

3. Switch off the engine and remove the ignition key.

Place a “maintenance work in progress” sign in the cab.

4. Place a container below the filter to collect any oil that

may leak during the replacement procedure.

5. Unscrew the filter cartridge with a band type spanner

and remove (g.20/D).

6. Clean the lter tting with a clean cloth (ensure the cloth does

not leave any uff) and ensure the old O-ring is removed.

7. Take the new lter and ll it with one of the hydraulic oils ap-

proved by DIECI. Lubricate the new O-ring with the same oil.

8. Screw up the lter using your hands. Ensure the O-ring

lubricated previously is positioned correctly.

9. Start the machine and check there are not any leaks.

- CAUTION:

Exhausted oil is a potential danger to the environment

and must be disposed of appropriately

Loading...

Loading...