Instructions for use Oxylog 3000 plus SW 1.n 125

Reprocessing

Surface disinfection with cleaning

Components:

– Surface of the device and other uncritical

components

Prerequisites:

– The surface disinfectant has been prepared in

accordance with the manufacturer's

instructions.

– The manufacturer's instructions, e.g., regarding

shelf life or application conditions, are

observed.

– An uncontaminated, lint-free cloth soaked in

surface disinfectant is used for the cleaning

surface disinfection.

Cleaning

1 Wipe off obvious soiling using a disposable

cloth (or a similar cloth) soaked in surface

disinfectant and dispose of it.

2 Wipe all surfaces. After that, there must no

longer be any soiling visible.

Surface disinfection

1 Wipe cleaned surfaces again to visibly wet all

surfaces to be disinfected with surface

disinfectant.

2 Wait for the surface disinfectant contact time.

3 At the end of the contact time, moisten a new,

uncontaminated and lint-free cloth with water

(at least drinking water quality).

4 Wipe all surfaces until no remains of the surface

disinfectant, such as foam residue or streaks,

are visible.

5 Wait until the surface is dry.

6 Check the surfaces for visible damage and, if

necessary, replace the product.

Machine cleaning with thermal

disinfection

Use a washer-disinfector that meets the

requirements of the ISO 15883 standard. Dräger

recommends the use of a load carrier for

anesthesia accessories and ventilation

accessories. Follow the manufacturer's instructions

for the washer-disinfector.

Components:

– Breathing valve, breathing hose, flow

measuring lines, angled connector, flow sensor

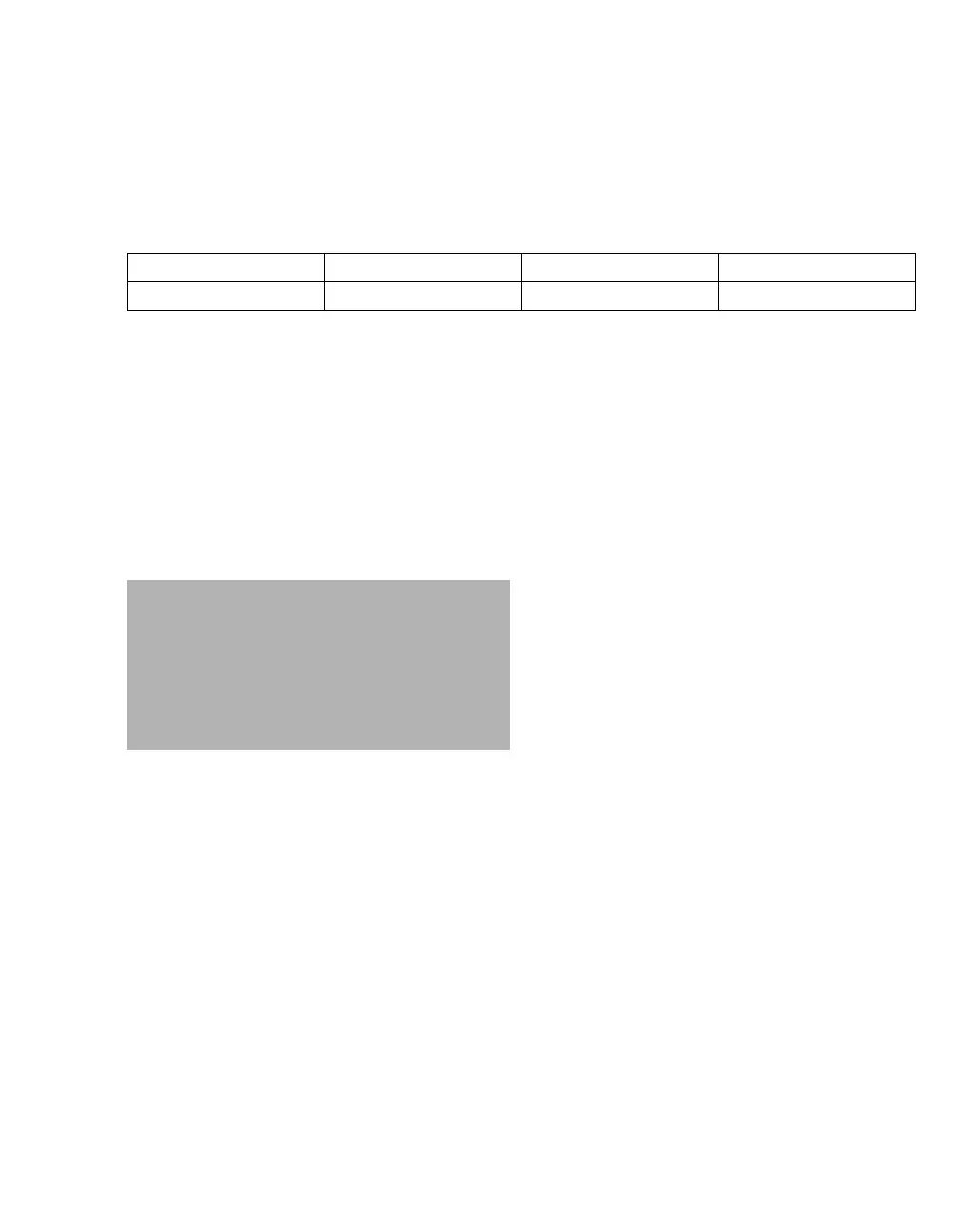

Surface disinfectant Manufacturer Concentration Contact time

Dismozon plus BODE Chemie 1.6 % 15 minutes

WARNING

Risk due to penetrating liquid

Penetrating liquid may cause the following:

– Damage to the device

– Electric shock

– Device malfunctions

Ensure that no liquid penetrates the device.

Loading...

Loading...