Reprocessing

128 Instructions for use Oxylog 3000 plus SW 1.n

Dräger states that oxygen-releasing agents and

chlorine-releasing agents may cause color change

in some materials. Color change does not indicate

that the product is not functioning correctly.

Other surface disinfectants are used at one's own

risk.

Reprocessing procedures

Manual cleaning followed by disinfection by

immersion

The following components can be can be cleaned

manually, followed by disinfection by immersion:

– Breathing valve

– Breathing hose

– Flow measuring lines

– Angled connector

–Flow sensor

The following disinfectants were compatible with

the material at the time of testing:

Steam sterilization

The following components can be steam sterilized:

– Breathing valve

– Breathing hose

– Flow measuring lines

– Angled connector

– Flow sensor

Prerequisites:

– The components have been cleaned,

disinfected, and are dry.

– Use a steam sterilizer that meets the

requirements of the ISO 17665 standard.

Dräger recommends steam sterilization with

fractionated vacuum.

Procedure:

1 Sterilize the components (maximum 134 °C

[273.2 °F], 10 min).

2 Check the components for visible damage and

replace if necessary.

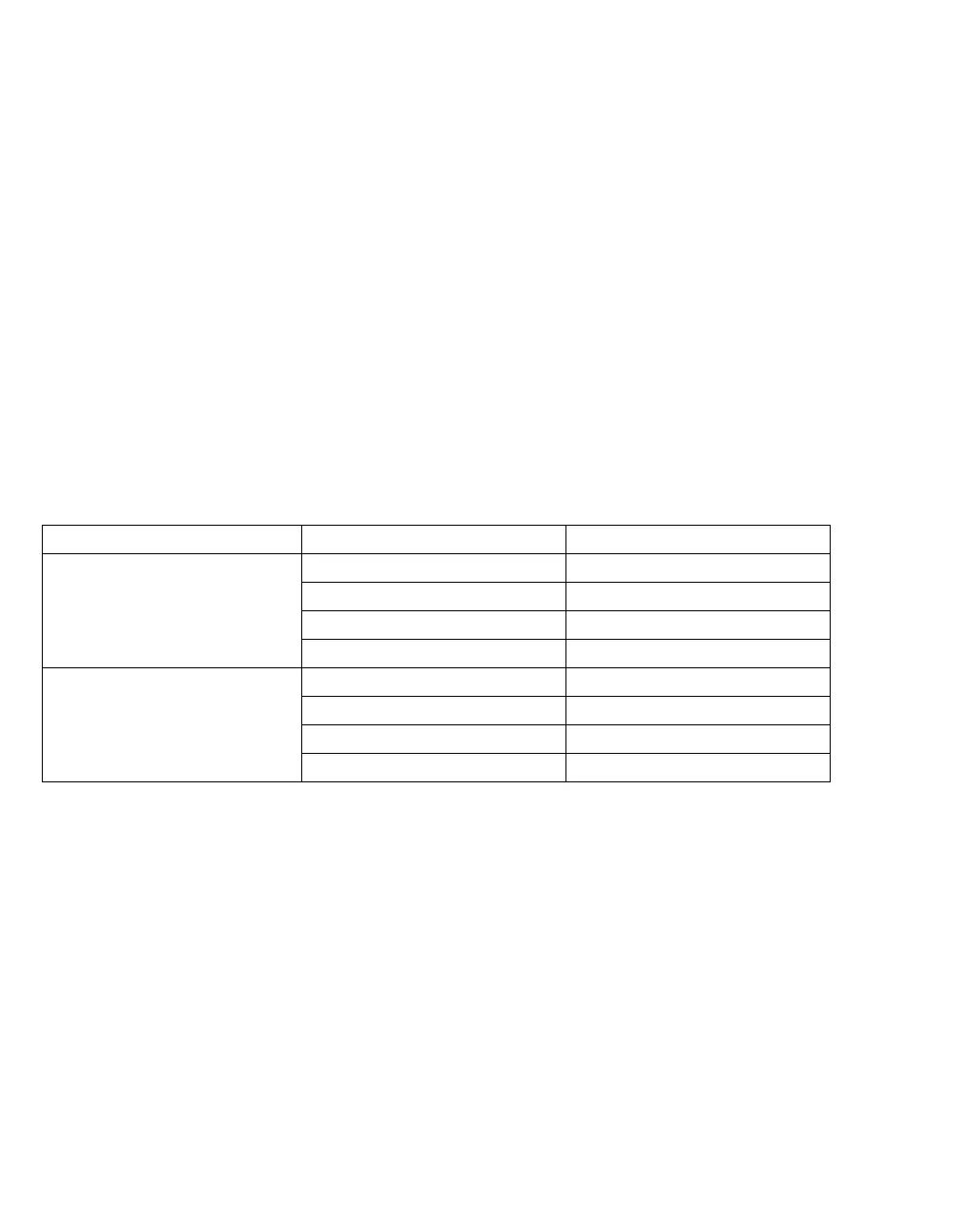

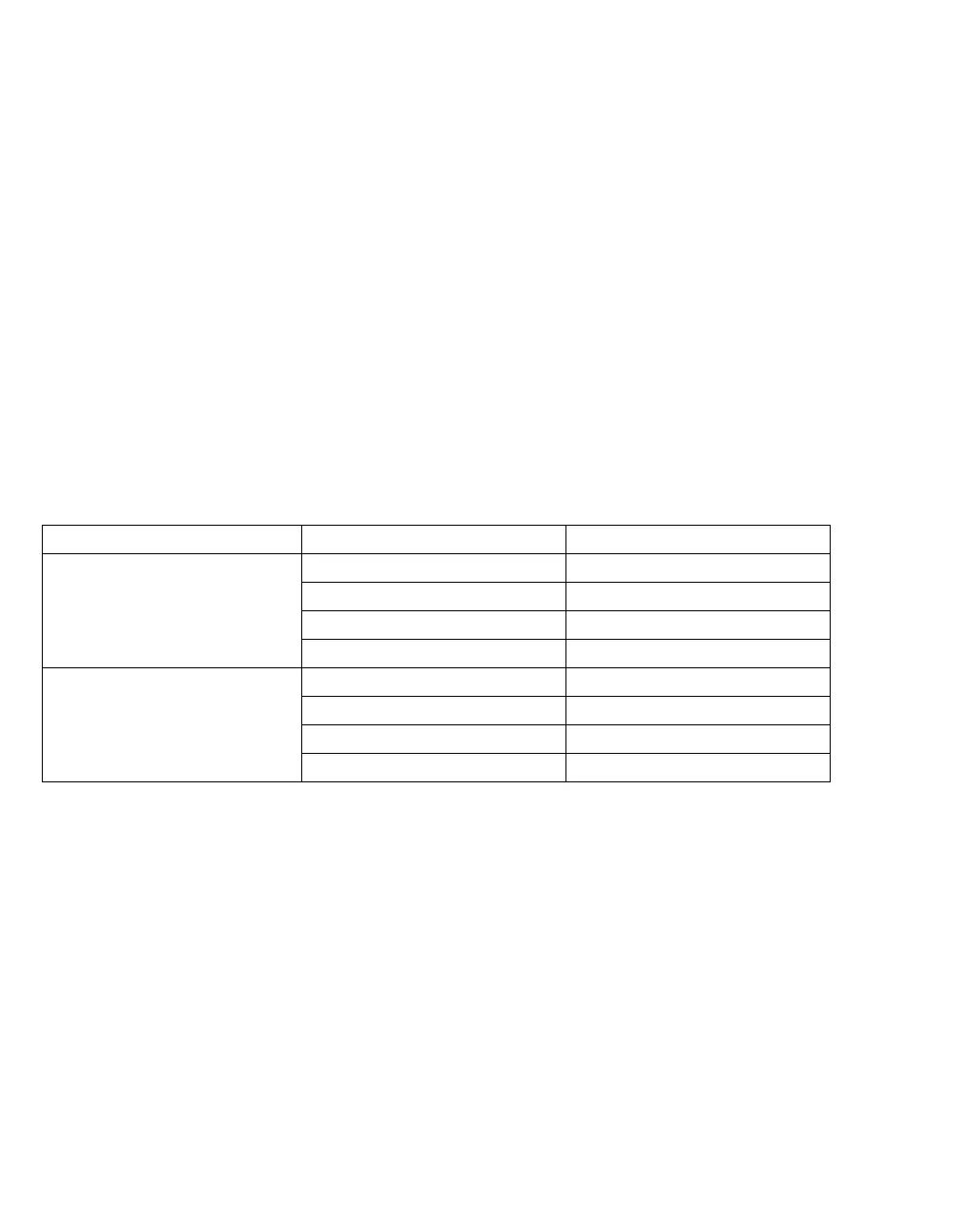

Component Agent Manufacturer

Breathing valve, breathing hose,

angled connector

Cleaning agent:

Neodisher LM2 Dr. Weigert

Disinfectant:

Korsolex Extra BODE Chemie

Flow sensor Cleaning agent:

Sekusept Pulver CLASSIC Ecolab USA

Disinfectant:

Korsolex extra BODE Chemie

Loading...

Loading...