Adjusting the bobbin case lifter

56 Service Instructions 867 - 04.0 - 10/2019

7. Tighten the threaded pin (3).

8. Push the cover (4) upwards.

9. Tighten the screw (5).

11.2 Adjusting the timing for lifting

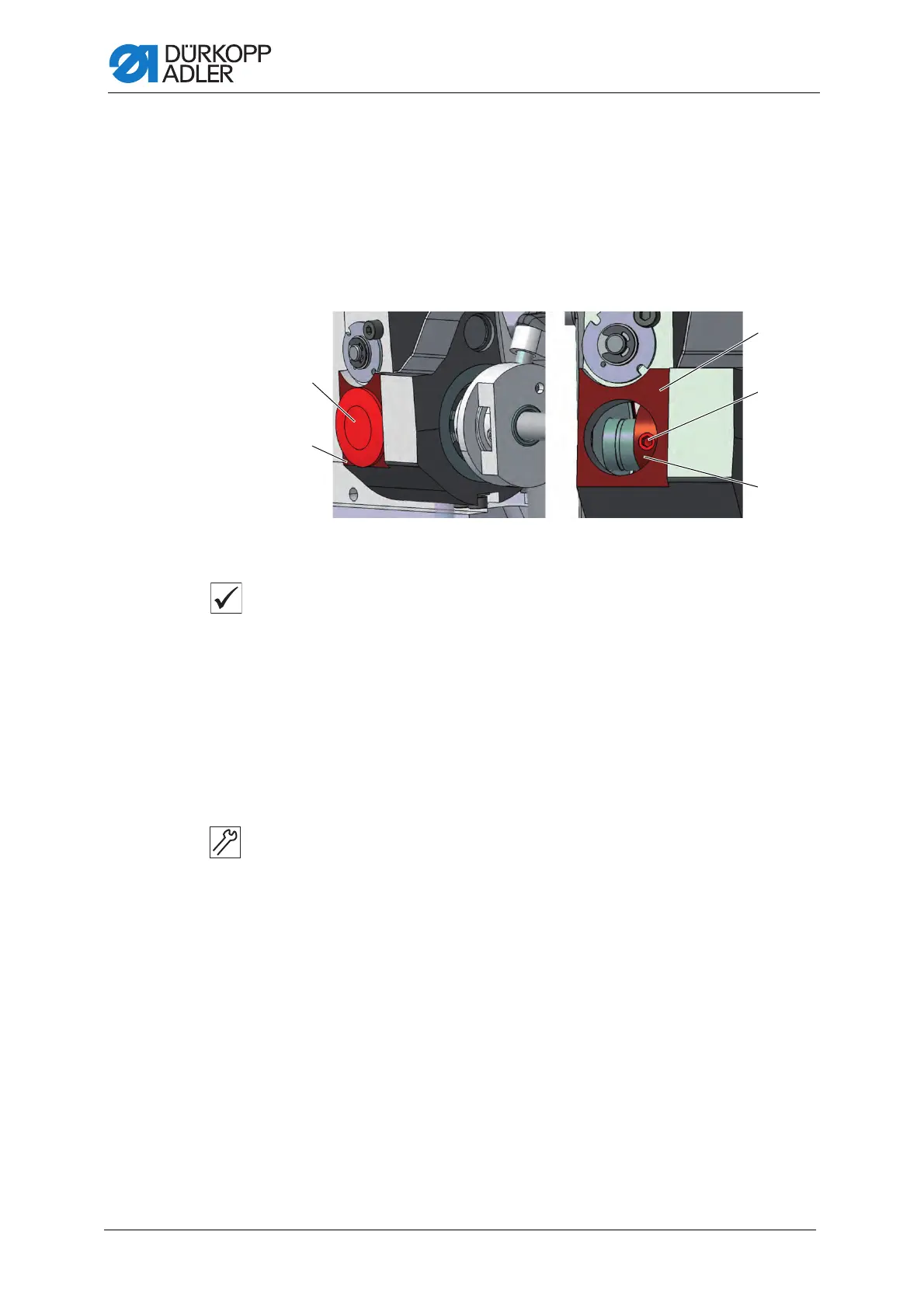

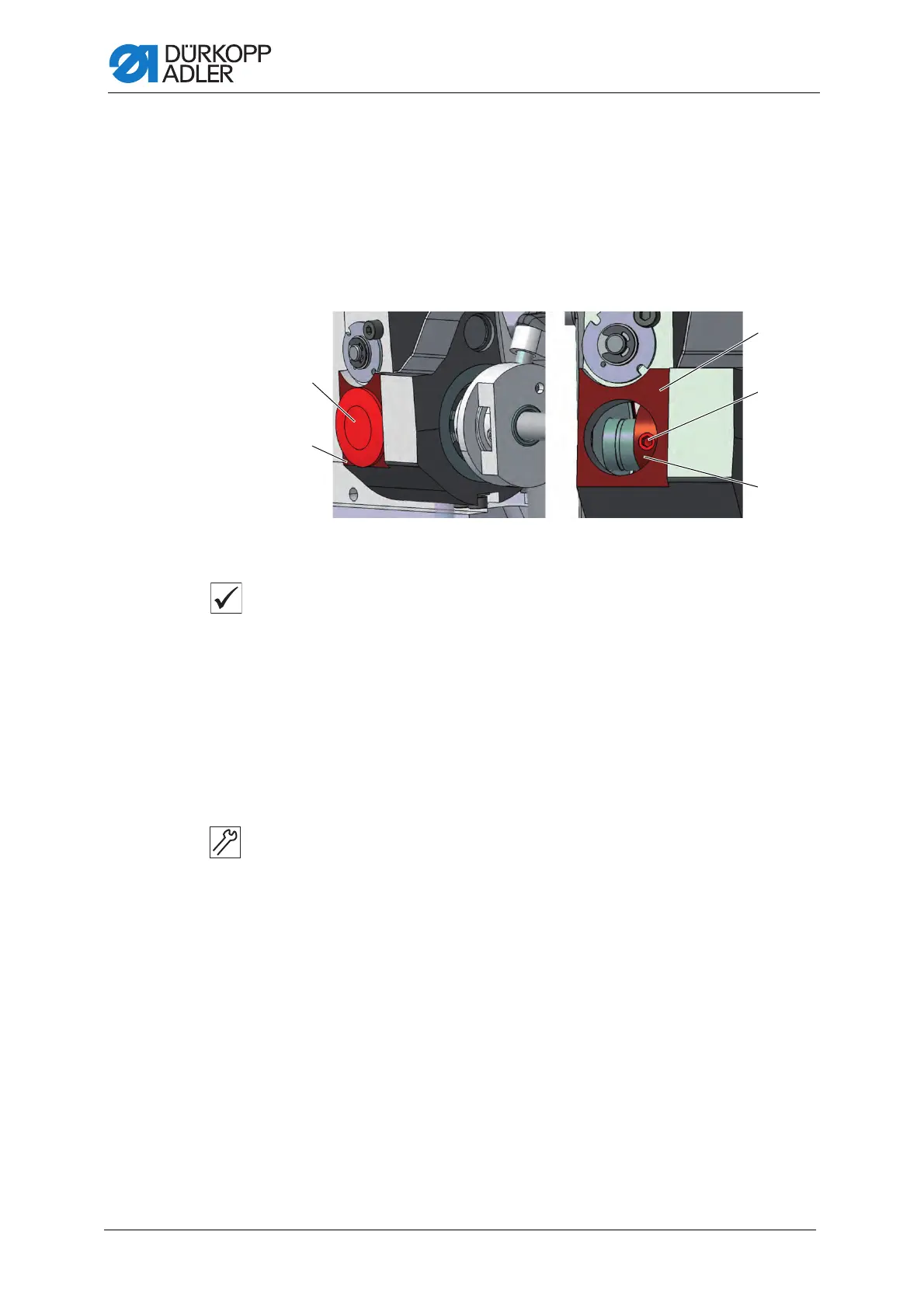

Fig. 40: Adjusting the timing for lifting

Proper setting

The bobbin case lifter starts to open exactly at the point when the hook tip

is located below the bobbin case lifter after the loop is taken up.

In 1-needle machines, this happens when the handwheel position is

approx. 100°.

In 2-needle machines, this happens when the handwheel position is

approx. 100° for the right-hand hook, and when the handwheel position

is approx. 300° for the left-hand hook.

For 100° or 300°, the threaded pin (4) is exactly in the middle of the open-

ing. (Insert allen key in the threaded pin for orientation.)

To adjust the timing for lifting:

1. Tilt the machine head ( p. 14).

2. Remove the plug (1) on the bottom side of the hook housing (2).

3. Loosen the threaded pin (4) through the opening.

4. Turn the handwheel until the hook tip is exactly below the bobbin case

lifter.

5. Use the allen key to turn the control cam (3) so that the bobbin case

lifter opens at the correct point in time.

6. Tighten the threaded pin (4).

7. Insert the plug (1) into the opening.

8. Perform a sewing test.

(1) - Plug

(2) - Hook housing

(3) - Control cam

(4) - Threaded pin

Loading...

Loading...