Position of the hook and needle

Service Instructions 867 - 04.0 - 10/2019 49

10 Position of the hook and needle

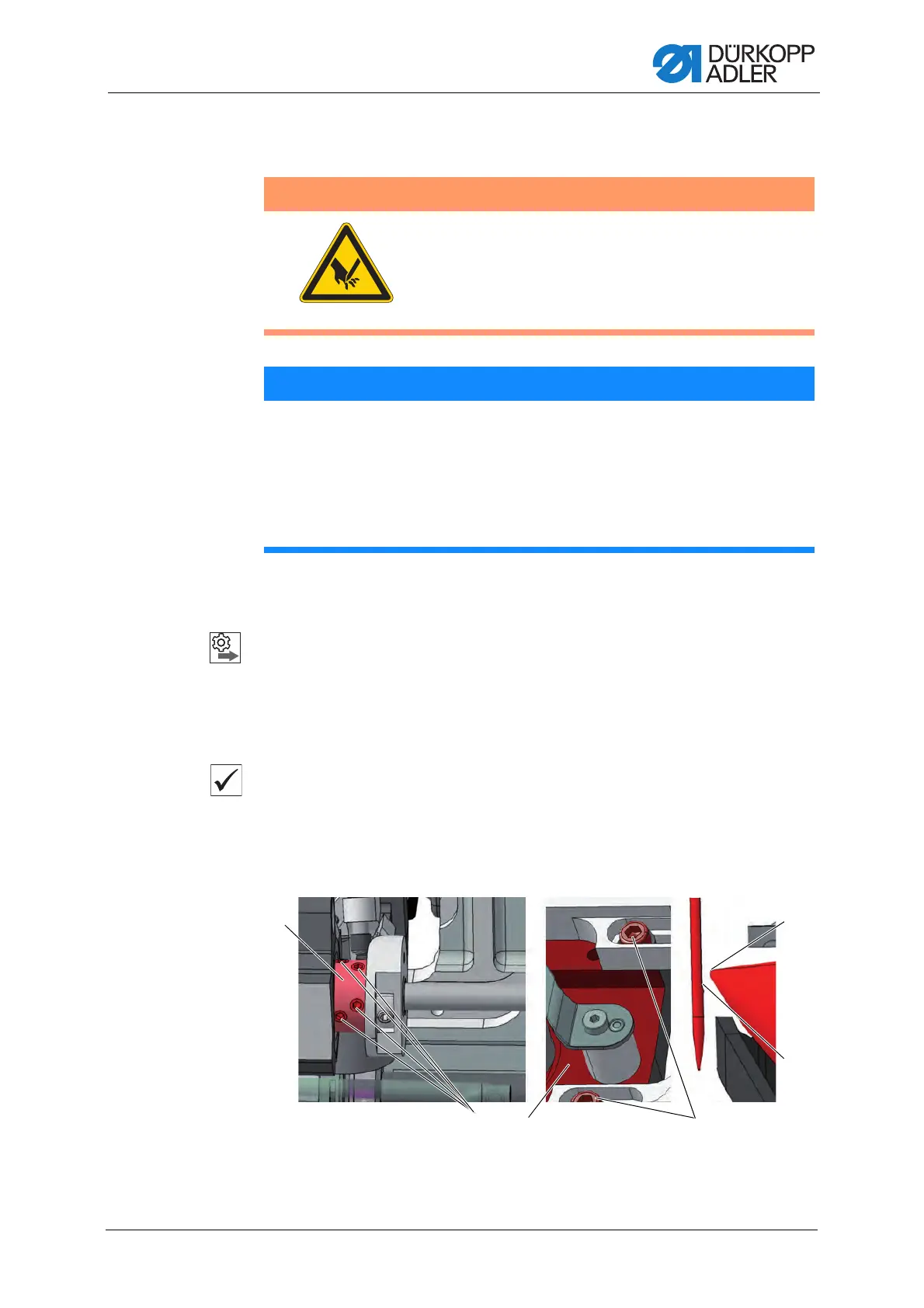

10.1 Adjusting the hook side clearance

Order

First, check the following settings:

• Needle bar linkage is aligned correctly ( p. 45)

• Looping stroke position ( p. 50)

Proper setting

Machine is locked in place at position 1 ( p. 22).

The distance between the hook tip and the groove of the needle is no

greater than 0.1 mm.

Fig. 32: Adjusting the hook side clearance

WARNING

Risk of injury from sharp and moving parts!

Puncture or crushing possible.

Move the machine into the service routine before

adjusting the position of the hook and the needle.

NOTICE

Property damage may occur!

There is a risk of machine damage, needle breakage or damage

to the thread if the distance between needle groove and hook tip

is incorrect.

Check and, if necessary, readjust the distance to the hook tip after

inserting a new needle with a different size.

(1) - Set collar

(2) - Threaded pins

(3) - Hook support

(4) - Screws

(5) - Needle groove

(6) - Hook tip

Loading...

Loading...