EPSON WF-C5790/WF-C5790a/WF-C5710/ET-8700/WF-C5210/WF-C5290/WF-C5290a Revision A

Configuration and operating principles Operating principles 49

Confidential

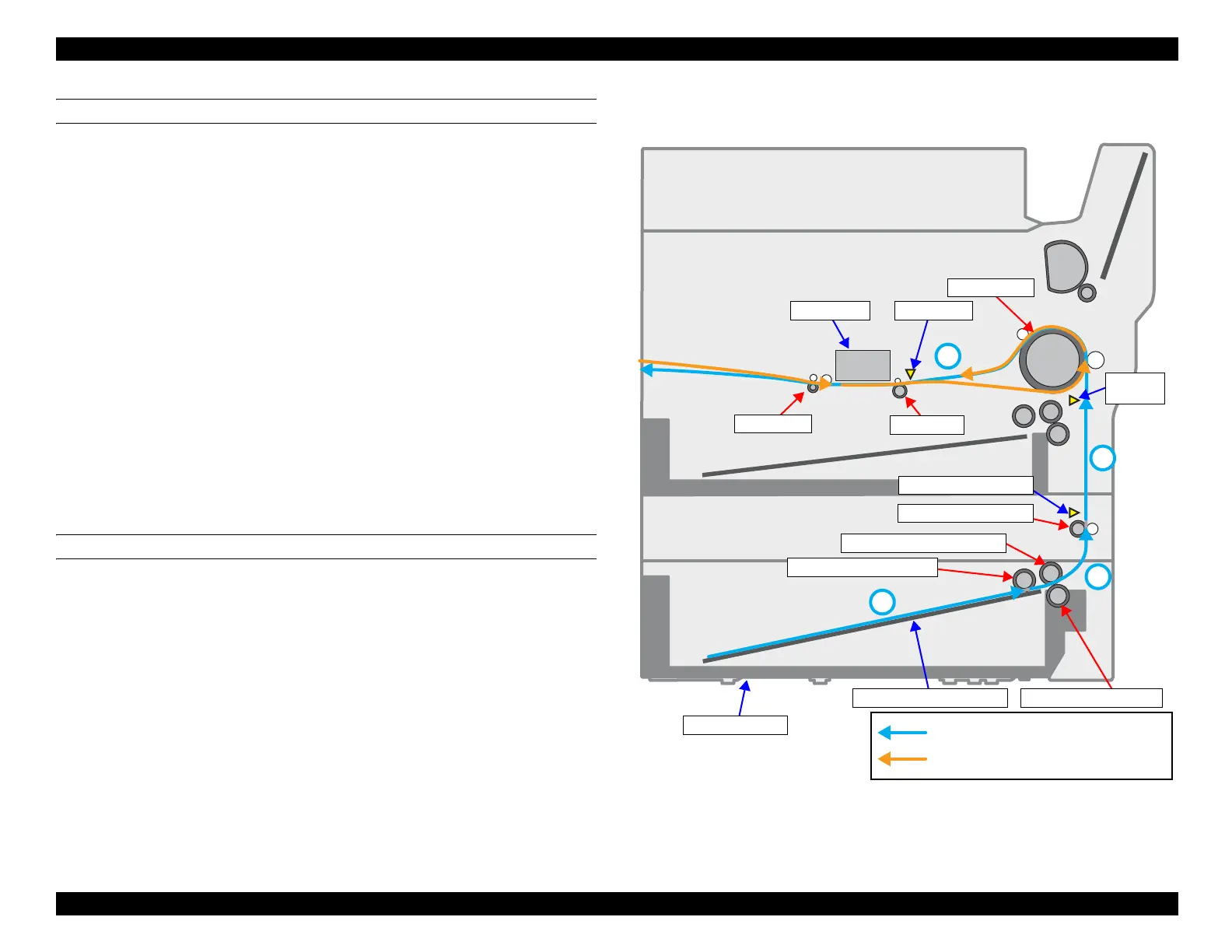

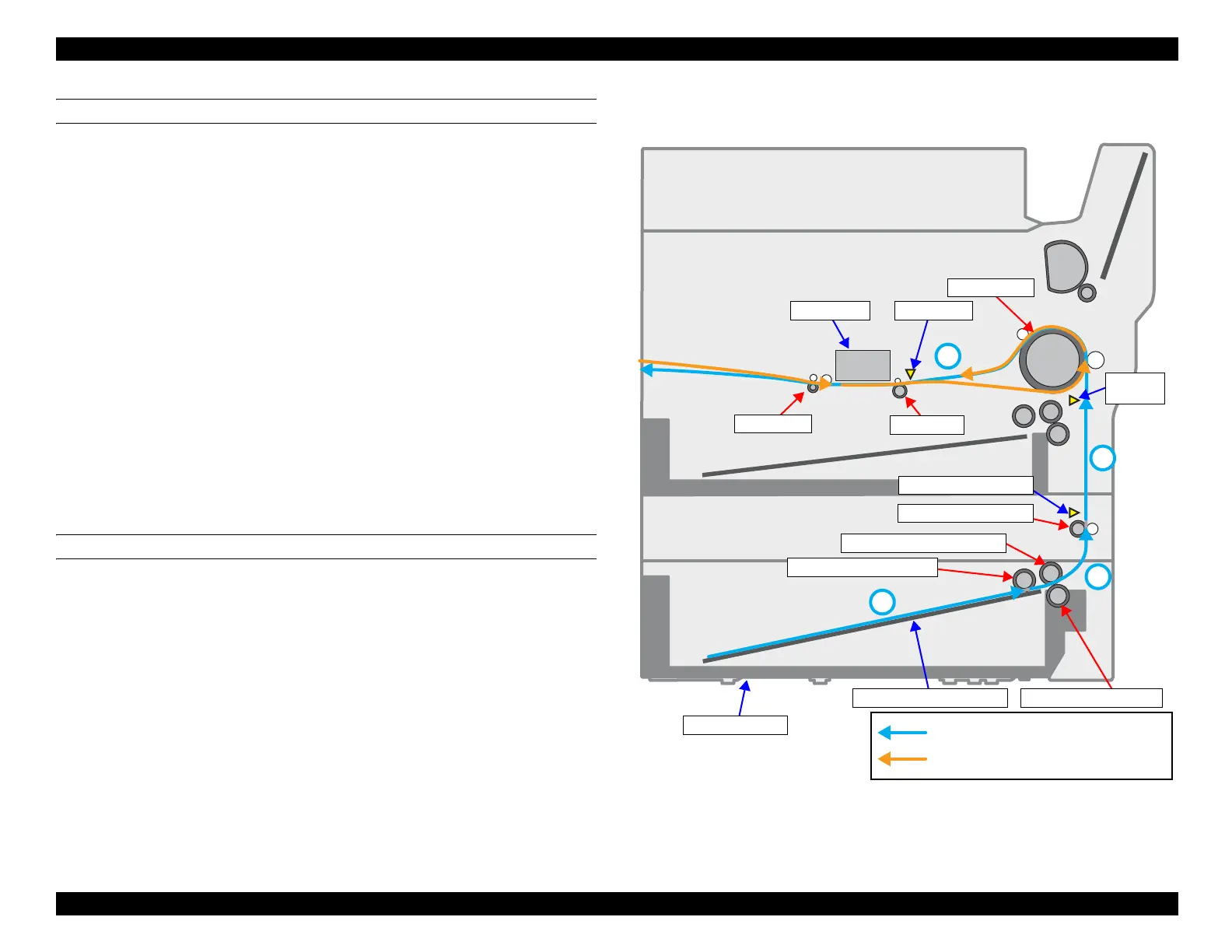

FEEDING FROM OPTIONAL CASSETTE (PAPER CASSETTE 2)

1. The drive of the Lift Motor is transferred to the optional hopper-up

mechanism parts, which lifts up the Optional Cassette Hopper, and the

paper set in Paper Cassette 2 comes in contact with the Optional Pickup

Roller.

2. The ASF Motor is driven, and the Optional Pickup Roller conveys paper to

the Optional Separation Roller. The paper conveyed to the Optional

Separation Roller is separated from the second paper by the Optional

Separation Roller and Optional Retard Roller, and is conveyed to the

Vertical Feed Roller.

3. The paper conveyed to the Vertical Feed Roller is passed through the

Optional Feed Sensor by the Vertical Feed Roller, and is conveyed up to

the position where it is detected by the Feed Sensor of the printer.

4. When the Feed Sensor detects a paper, the ASF Motor is driven, the paper

is conveyed by the Middle Roller up to the position where it is detected by

the PE Sensor, and printing is performed in the same way as the front

cassette paper feeding.

FEEDING PATH DURING THE AUTOMATIC DUPLEX PRINTING

When automatic duplex printing is performed, an automatic judgment function

for the drying time of the printed surface after surface printing is provided in

order to avoid friction of the printed surface. If drying is determined to be

necessary after surface printing, two-stage printed surface drying wait is

performed at two locations, namely on the Stacker (when the paper is held by

the PF Roller and the Driven Roller) and inside the Rear Unit (when the Middle

Roller has held the end of the paper).

In this product, the temperature and humidity of the operating environment is

detected by loading a Temperature and Humidity Sensor, and the throughput is

improved by setting an appropriate drying time in accordance with the

operating environment.

Figure 3-28. Paper loading/feed path (2)

1

2

3

4

Feeding path from the Paper Cassette 2

Automatic Duplex Printing feeding path

Paper cassette 2

Optional Retard Roller

Optional Separation Roller

Printhead

Optional Pick-up Roller

Middle Roller

PF Roller

EJ Roller

PE Sensor

Feed

Sensor

Optional Cassette hopper

Optional Feed Sensor

Vertical Feed Roller

Loading...

Loading...