5 Selection of the Measuring Point FLUXUS G60x

UMFLUXUS_G6V4-2EN, 2011-03-29 29

It is not always possible to meet both requirements at the same time. In these cases, the

measuring point has to be selected in such way that the influence of noise is min. and the

measuring point is as far from the disturbances of the flow profile as possible.

In the example, there is no area where both demands are met at the same time. The

measuring point has to be selected as far as possible from the elbow, at a point where

the influence of noise can be neglected: 3...(7.5 - 2) D on the right side of pipe

segment 1. In the example, a distance of 16 D from the elbow was selected.

Tabelle 5.5

example:medium: natural gas

pipe material: stainless steel

length of pipe segment 1: 20 D

length of pipe segment 2: 5 D

number of sound paths: 2

• area with developed flow profile:

disturbance source: 90°-Krümmer

recommended area for the measuring point: l 20 D (complete pipe segment 2) (see

Tab. 5.2)

• area with low influence of noise:

reflection point: flange

recommended area for the measuring point: l 3 D and outside of l = (7.5 ± 2) D on pipe

segment 1 (see Tab. 5.2)

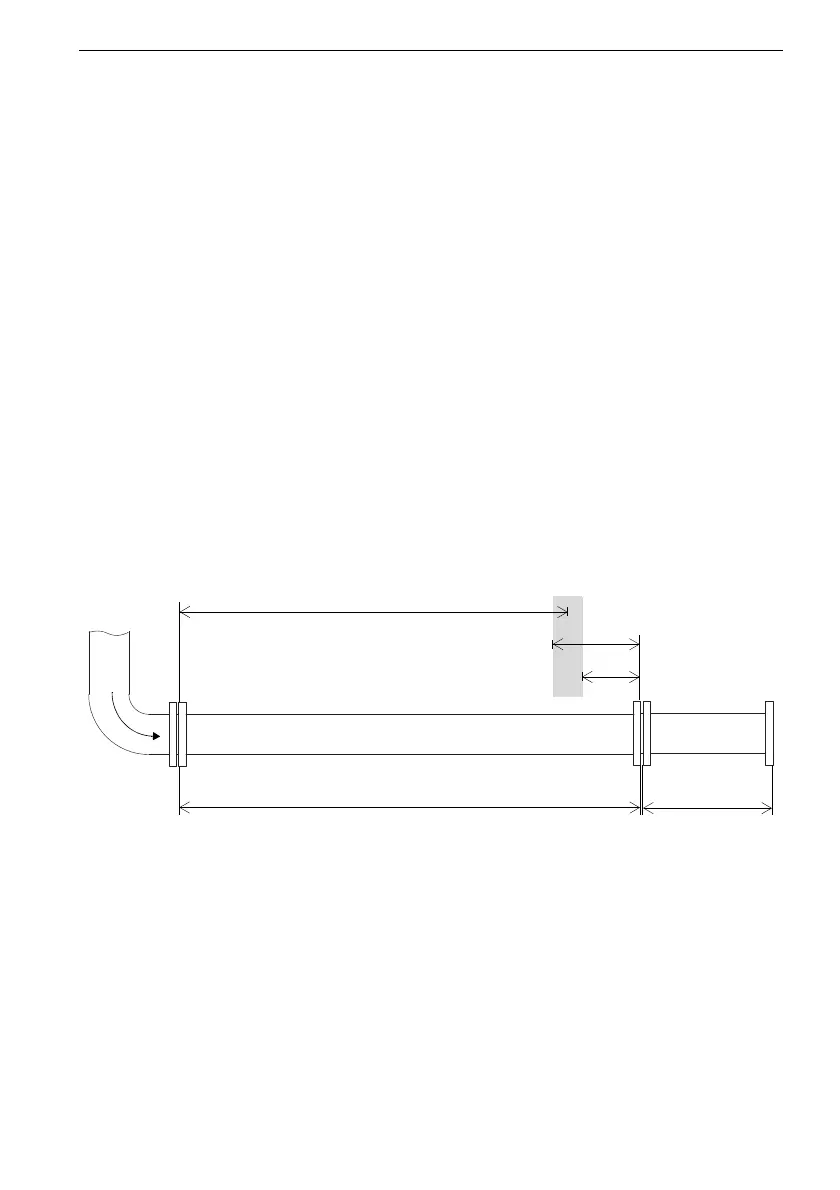

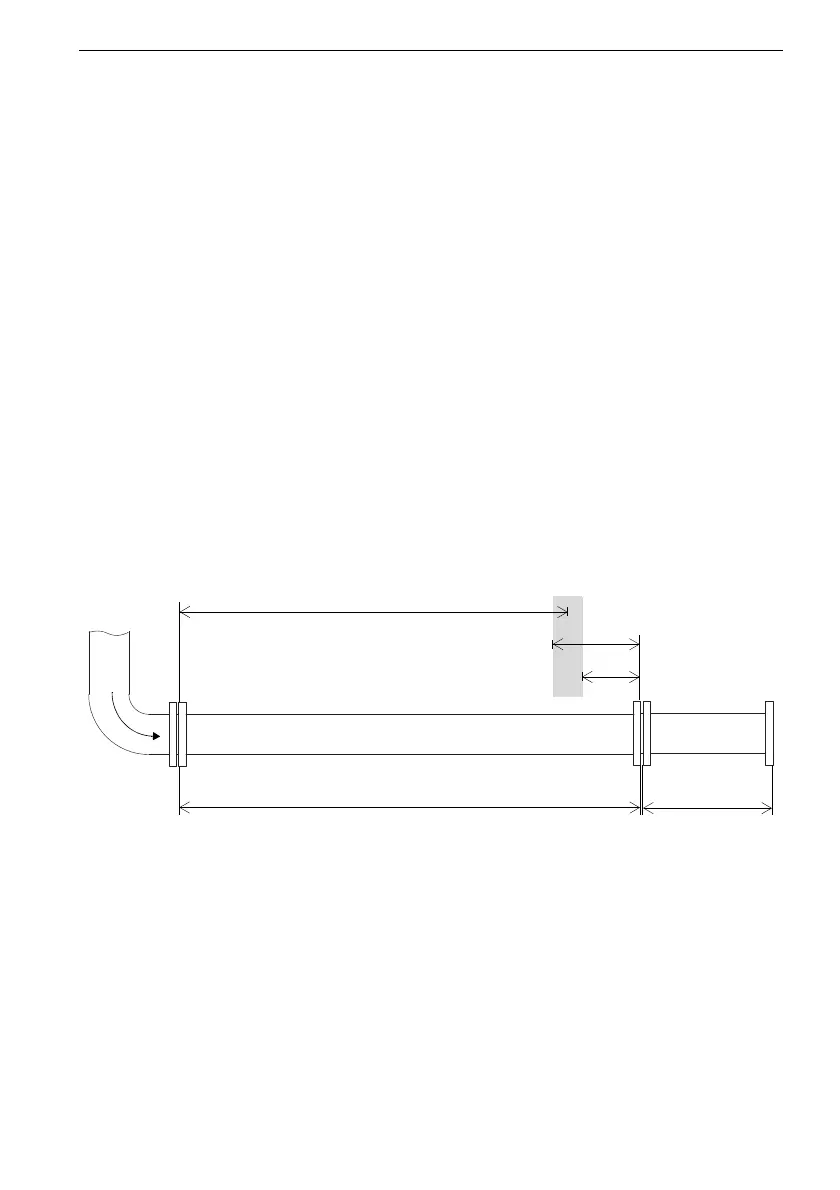

Fig. 5.1: Area for the measuring point with low influence of noise

and not fully developed flow profile

5 D

20 D

(7.5 - 2) D

3 D

16 D

Loading...

Loading...