General Procedures

Advanced Punch Service Manual © Copyright 2009 GBC. All rights reserved. 6-11

6.9.2 Outputs

The output signals can be exercised using the printer routines using NVMs.

6.9.3 Printer Communication

6.9.4 Serial EEPROM Control

For the Advanced Punch to operate, all optical sensors must be clear. Any blocked sensor

or open door will prevent operation. The machine may operate in bypass mode with or

without a chip tray or die set. Both of these must be present to punch.

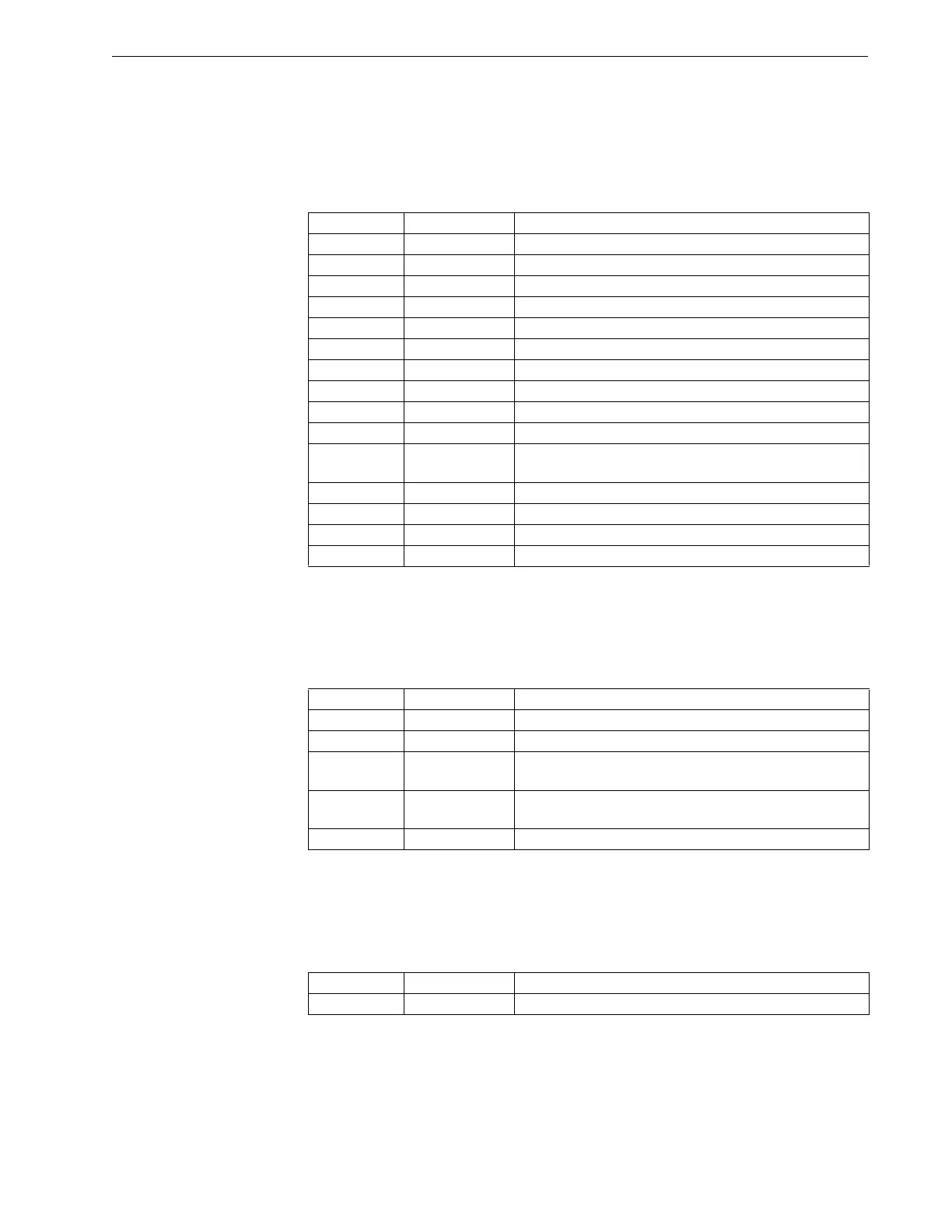

Table 6.2Output Devices

Output Type Function

Diverter DC Solenoid Diverts paper from bypass to punch sections

Brake DC Brake Stops the punch mechanism, keeps it in correct position

Clutch DC Clutch Clutches the punch mechanism to drive through paper

Backstop DC Solenoid Provides stop for paper to rest against during punching

Transport AC Motor Provides paper movement through machine

Punch AC Motor Provides power to punch the paper

Stepper 1 PWM Signal Controls Stepper Motor 1

Winding ON signal for stepper holding current

Stepper 2 PWM Signal Controls Stepper Motor 2

Winding ON signal for stepper holding current

LED 1 Chip Tray ON: Chip Tray missing, FLASHING: Chip Tray may be

full

LED 2 Die Set ON: Die Set not installed properly

LED 3 Door ON: Door is Open

LED 4 misfeed ON: Paper mis-fed in Machine

LED 5 Punch On ON: Punch Enabled

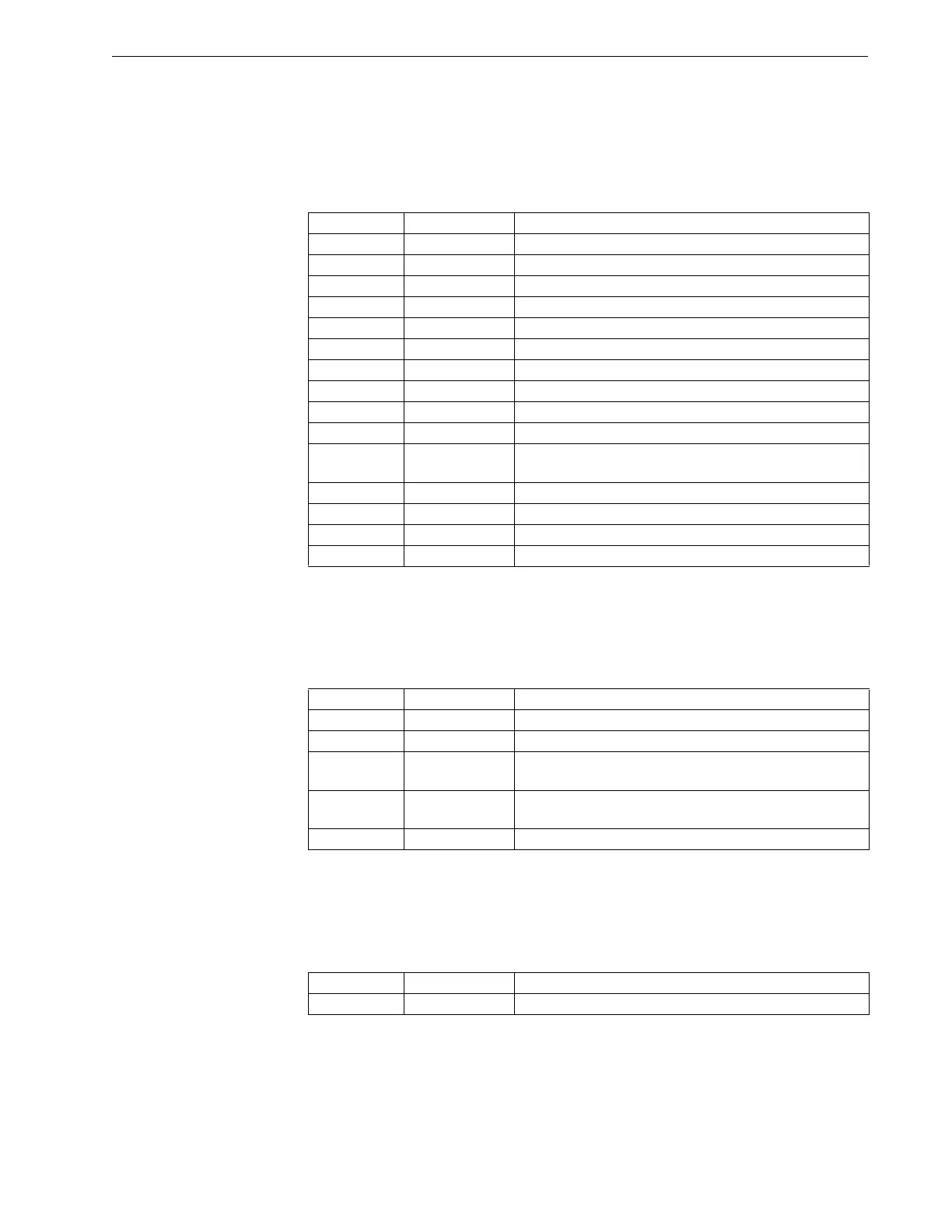

Table 6.3Printer Communication Devices

Device Type Function

Punch Input Printer turns on Punch enabled mode

Motor Input Printer turns on Advanced Punch Motor MT-C3 & VC-1

misfeed Output Punch signals a misfeed or the door is open (no

operation allowed)

Tray/Die Output Punch indicates tray or die set missing (bypass only

allowed)

Motor Input Printer turns on Advanced Punch motor BC-3 only

Table 6.4Serial EEPROM Device

Device Type Function

1 Input 3 Outputs Counts number of punches for die set full, Saves value

Loading...

Loading...