Section 2

2-10 © Copyright 2009 GBC. All rights reserved. Advanced Punch Service Manual

2.7.2 Back Gauge

2.7.3 Die Set

Under normal conditions, the Advanced Punch may experience one paper jam in

5000. Excessive paper jams, such as one in every 1000, requires servicing. The

cause may be the Die Set.

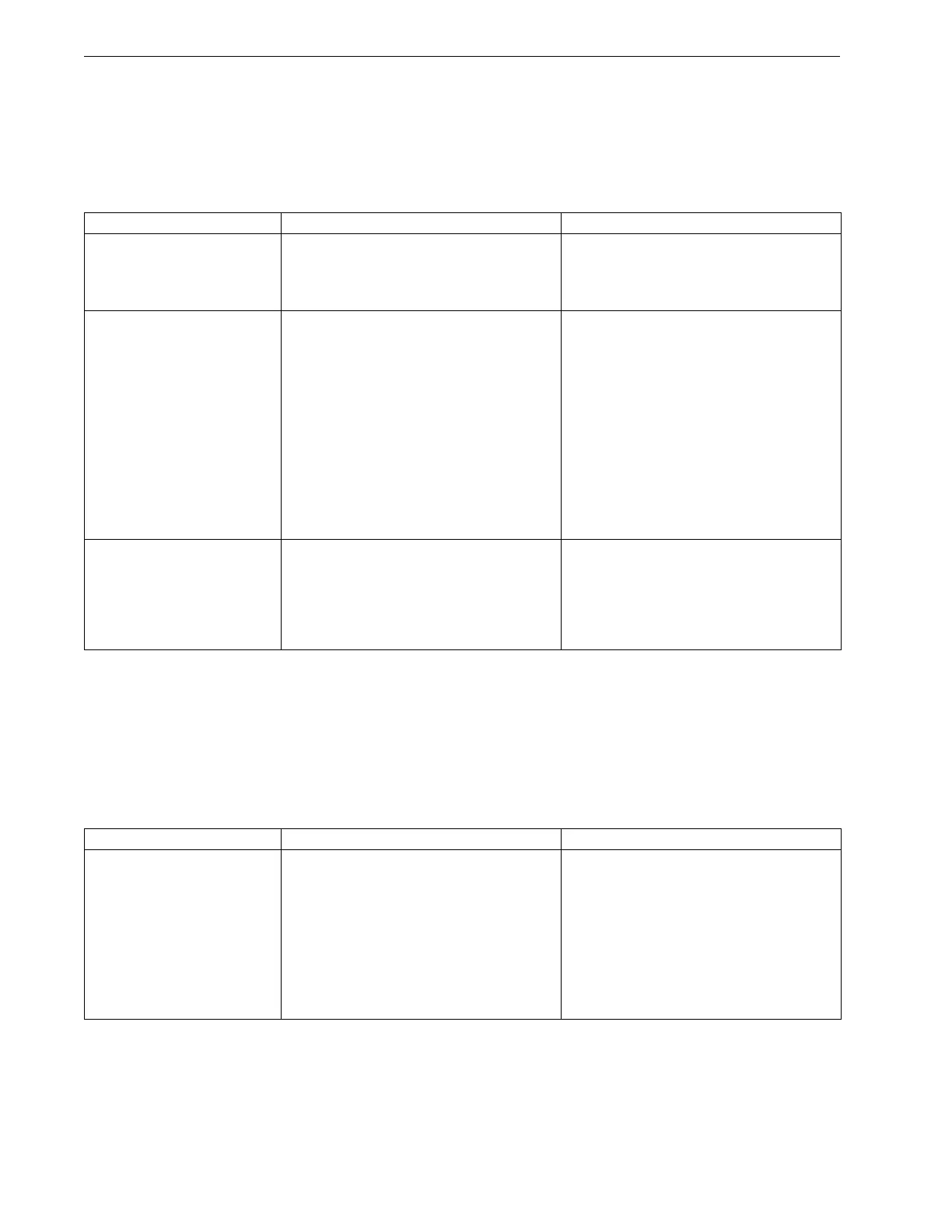

Table 2.2Back Gauge Troubleshooting

Symptom Probable Cause Corrective Action

Deep punch or angled deep

punch from leading edge of

the paper.

Broken weld on paper stop, Back Gauge

paddle.

Replace the unit. Refer to section 4.8.3

Broken or missing Back Gauge linkage

springs.

Replace the Back Gauge assembly as

explained in section 4.8

Cannot remove the Die Set. Back Gauge paddle is not in the fully

opened position and is contacting the Die

Set.

Turn the Punch Cycle Knob to ensure the

punch drive indicator is lined up with the

position indicator.

Broken weld on paper stop, Back Gauge

paddle.

Replace the unit.

Refer to section 4.8.3

Broken or missing linkage spring or springs. Replace the spring. See “Solenoid Spring

Replacement” on page 4-46.

Solenoid plunger stuck.

Clean the solenoid. See “Back Gauge

Solenoid Inspection and Cleaning” in

Section 1.4.11

.

Solenoid plunger worn.

Replace Back Gauge. See “Back Gauge

Assembly” in Section 4.8.

Punches occur 2 to 4” into the

sheet.

One or more broken or missing linkage

springs.

Replace the Back Gauge assembly as

explained in section 4.8

Back Gauge paddle is not fully closing,

leaving a gap that the paper can slip

through especially when using paper with

heavy curl.

Adjust Back Gauge adjustment. See “Back

Gauge Assembly Adjustment” on page 4-

48.

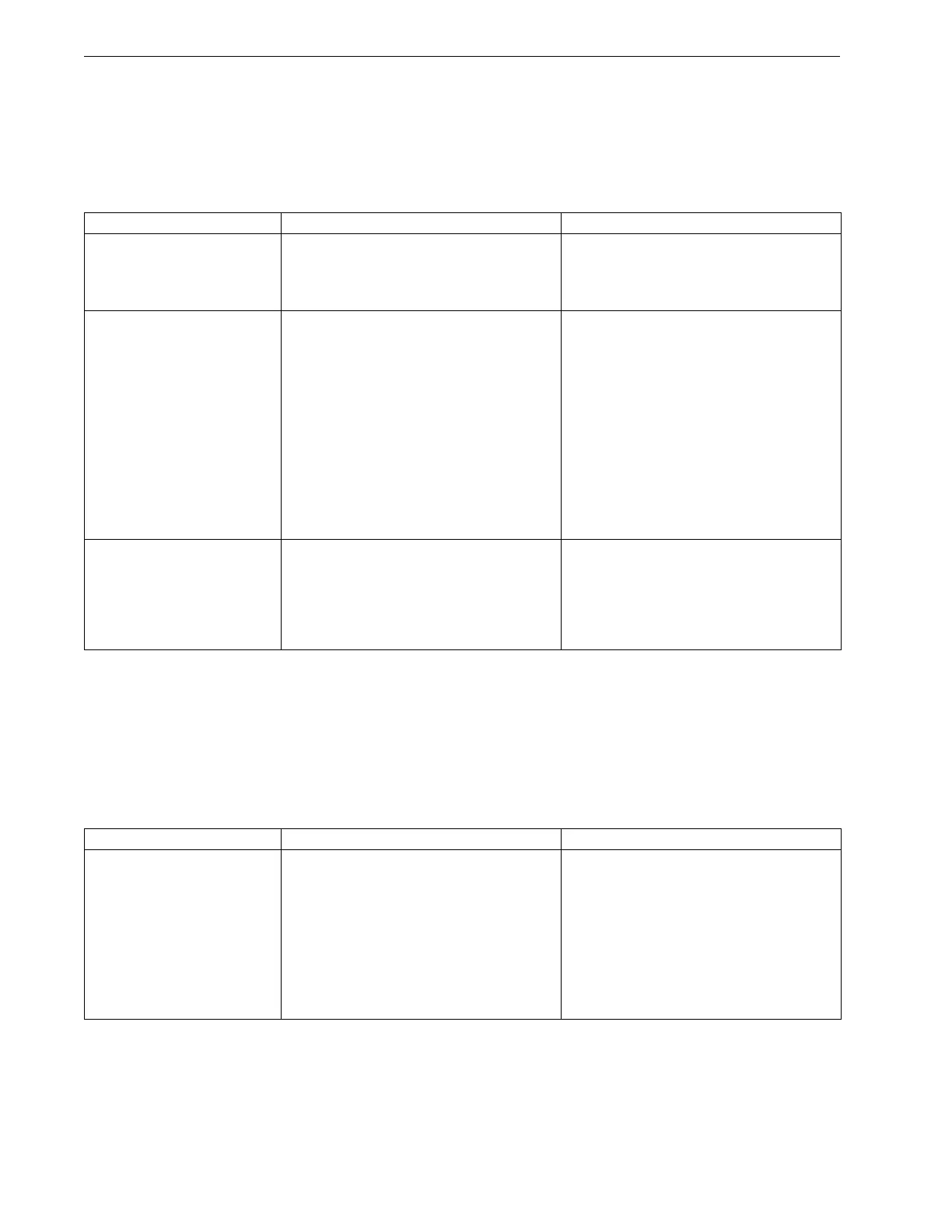

Table 2.3Die Set Troubleshooting

Symptom Probable Cause Corrective Action

Excessive

paper jams..

Paper does not exit after being

punched.

Worn Die Set. Replace Die Set if it is worn out, greater

than 500K cycles.

Defective Die Set. Replace.

Excessive oil on punch pins. Chad and

paper dust sticks to the punch pin tip.

Clean pins to remove excess oil. Lubricate

with approved lubricants only.

Refer to

Section 1.3.4.

Floating pressure bar not retracting. Replace pressure bar springs when

applicable. See “Floating Pressure Bar

Spring Replacement” on page 1-7.

Loading...

Loading...