Repair and Adjustment Procedures

Advanced Punch Service Manual © Copyright 2009 GBC. All rights reserved. 4-69

4.10Belt Replacement

Maintenance Schedule

Inspect every 750K cycles.

Replace as needed.

Procedure

Inspect all timing belts for wear, missing teeth, frayed edges, and cracks. The belts

should be slightly loose with approximately 1/4” deflection [1]. Belts that are too

loose will not drive properly and belts that are too tight can wear out prematurely

or damage their driven components.

Figure 4.79 Typical Belt Deflection.

To replace belts:

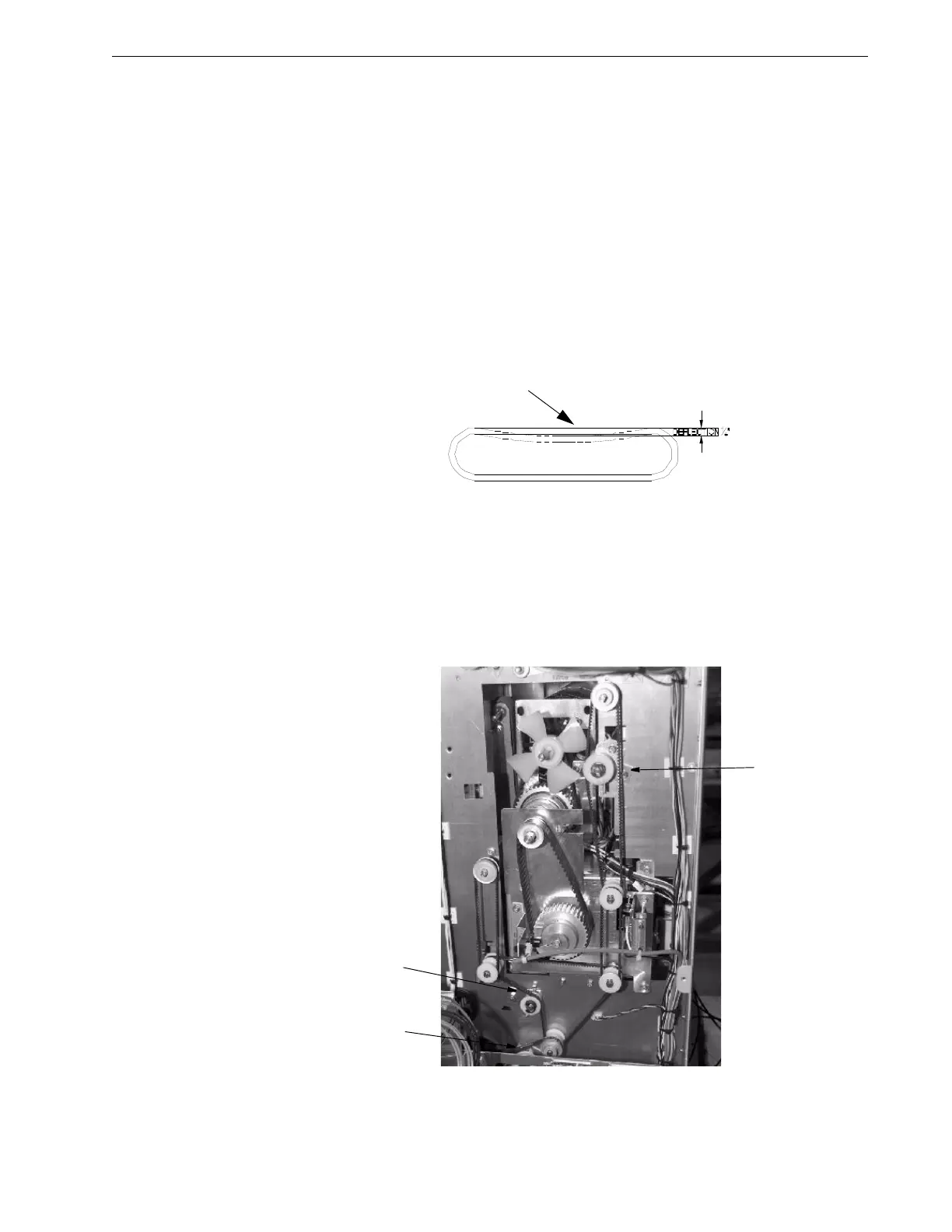

1. Loosen the screws of the 3 belt idlers [1].

Installation Note: When setting the belt tension, adjust the belt idlers so that the

belt has approximately 1/4" of deflection.

Figure 4.80 Belt Idler Locations.

Loading...

Loading...