Advanced Punch Service Manual © Copyright 2009 GBC. All rights reserved. 3-1

Section 3

Output Quality Analysis Procedures

This section contains information related to the quality of the output such

as hole quality or alignment.

3.1 RAP Hole Alignment Inspection Procedure

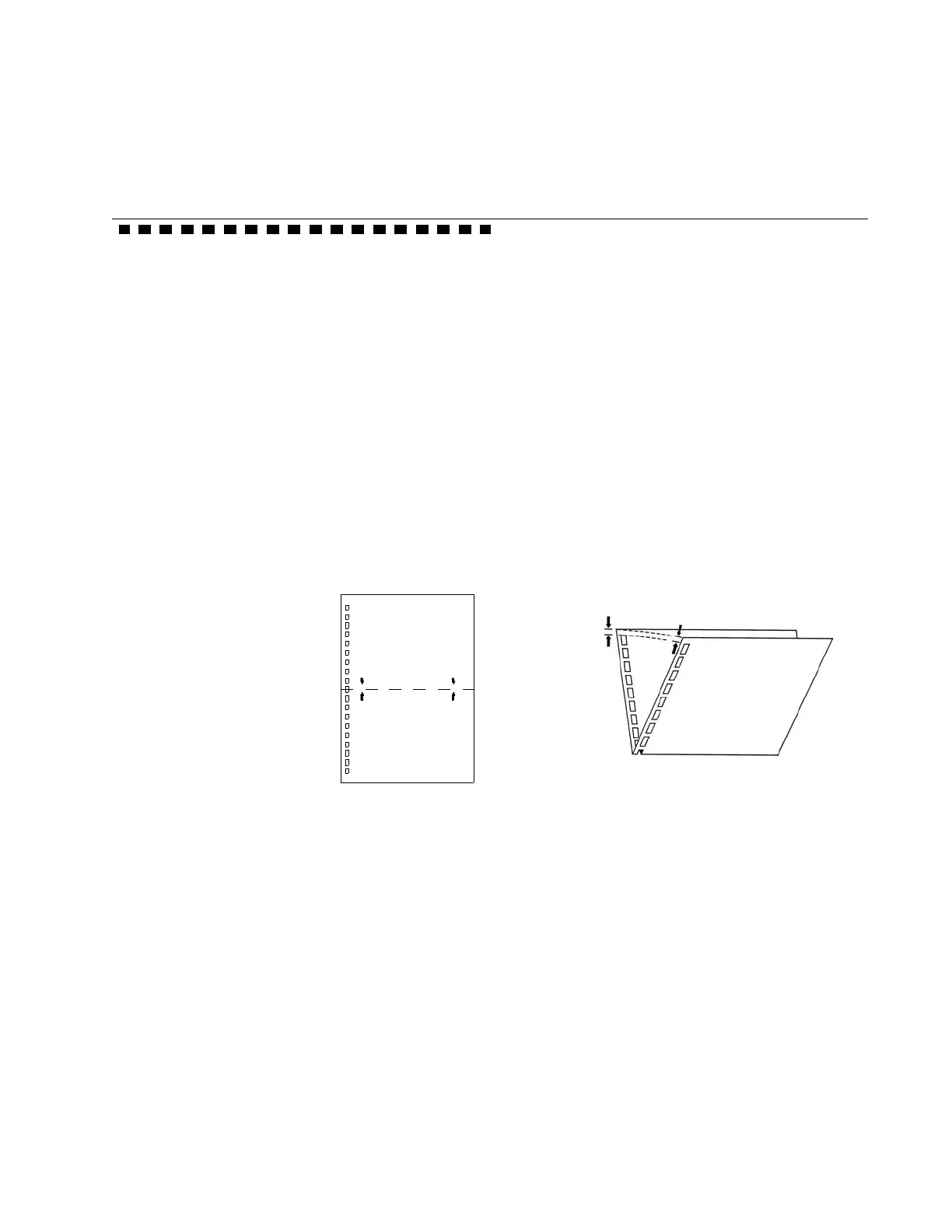

The holes in the paper should be in alignment from an end to end perspective as

shown in Figure 3.1. If not, go to Section 4 and follow the adjustment procedure

explained in Section 4.11

Figure 3.1 Hole Alignment on Finished Sheet.

3.2 RAP Hole Skew Check

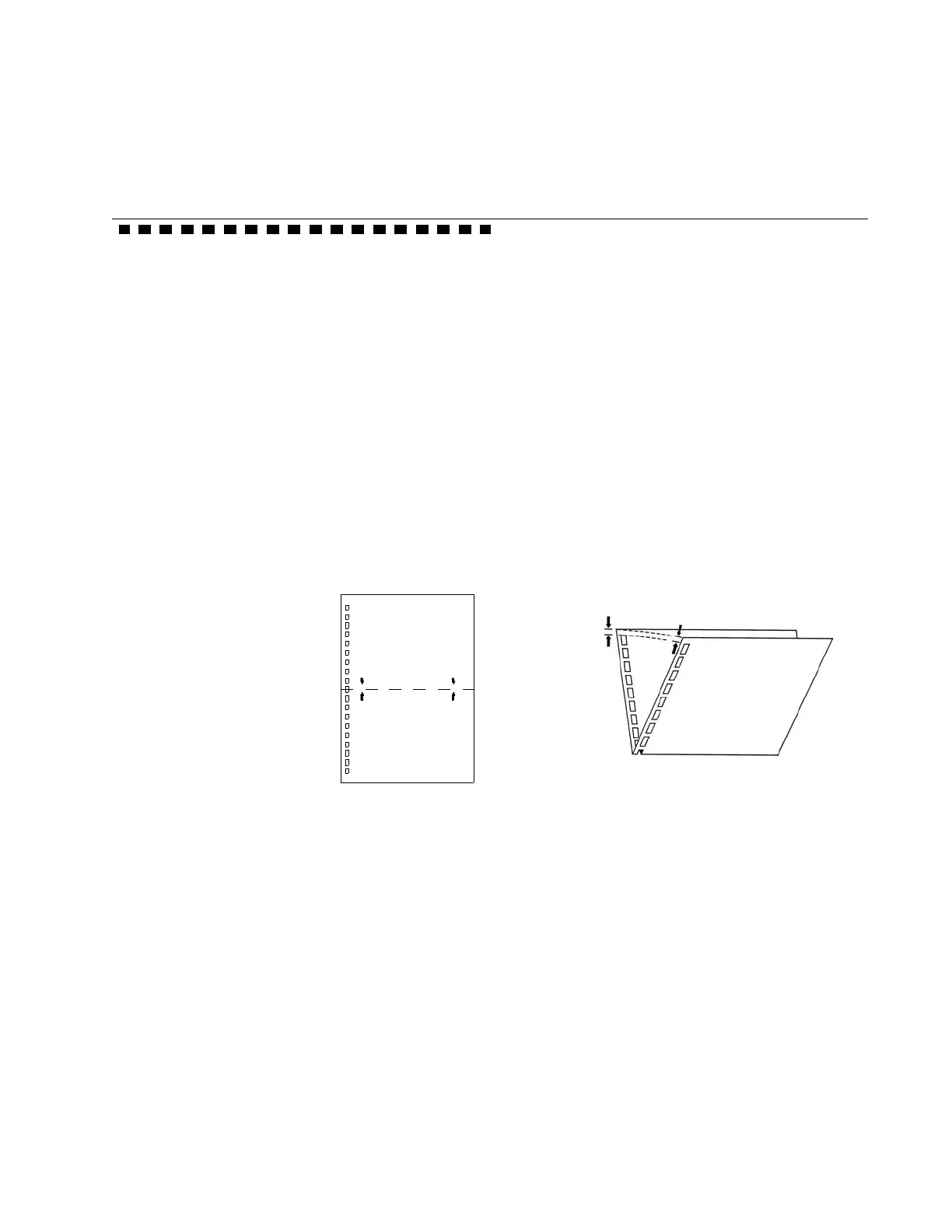

This RAP explains the procedure to follow when the holes in the paper are not in

alignment along the margin of the paper. One end is further from the edge than

the other end as shown in Figure 3.2

1. Inspect the Back Gauge Solenoid. It is free of Chad build up.

N. Clean the chad following procedure 1.4.11

Y. Go to next step.

2. Check the service records of this machine. The Back Gauge Assembly is within

the normal maintenance interval.

N. Replace the Back gauge Assembly as explained in procedure 4.8

Loading...

Loading...