3.28 US (130519) 133/154

11 Troubleshooting

11.1 Indication of malfunctions

With HERMA 400 applicators the type of malfunction is indicated via the display (see section 11.2).

Also, the LEDs of the key pad will give an indication (see section 11.3 „Malfunction table (LED

indication)“).

Furthermore there is the possibility to connect a signal coumn to X10. With the usual allocation red

stands for malfunction, yellow for warning, and green for production.

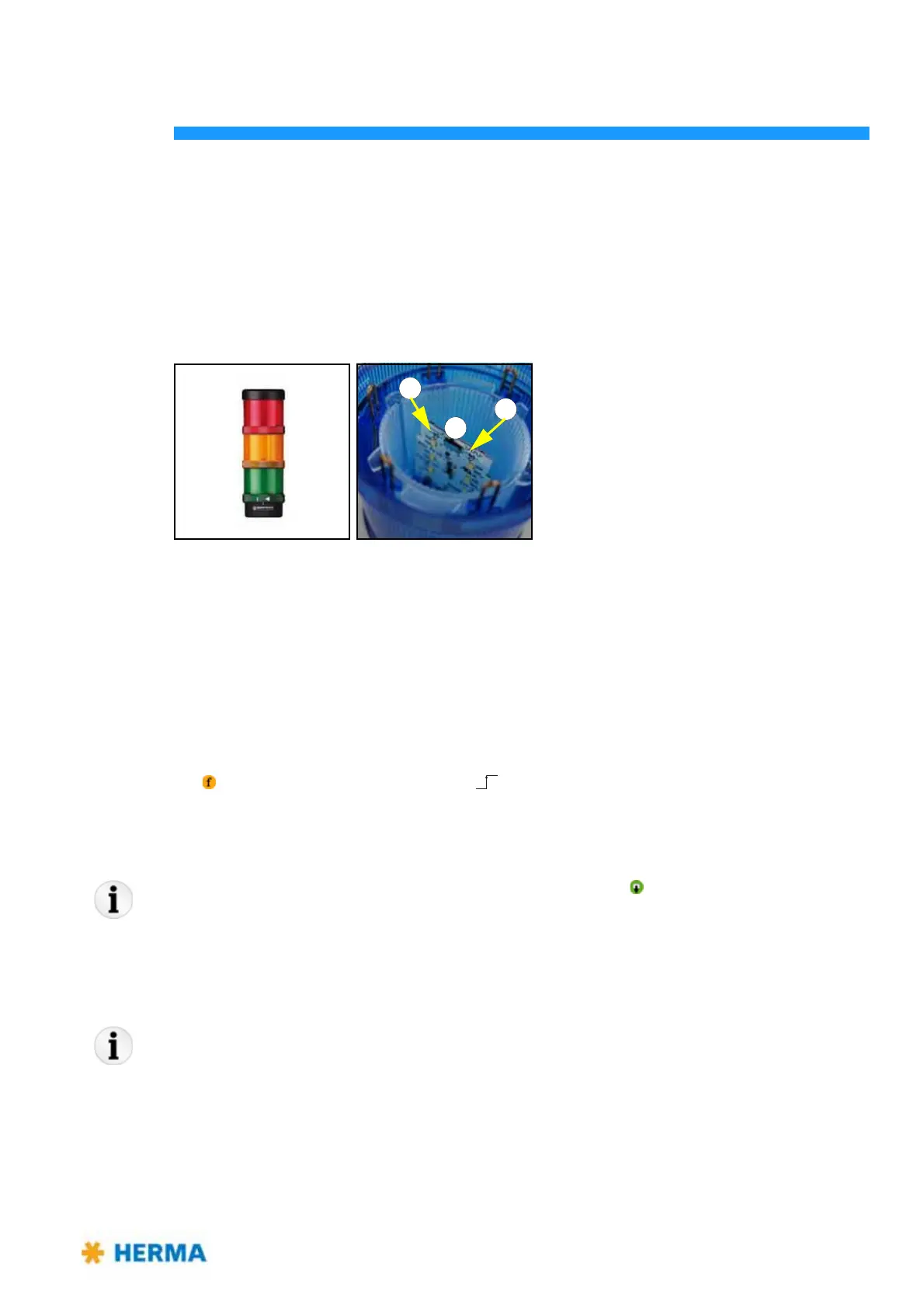

Note: The lamps can be switched over

between blinking (position a) and permanent light

(position b), or flash light and EVS flash. To do so actuate the little switch 1 at the LED

board. Switch positions are marked by symbols.

Acknowledging malfunctions

If the applicator is connected to a superordinate control malfunctions very often are acknowledged

centrally (e.g. at a touch display).

Directly at the applicator or via superordinate control malfunctions are acknowledged by pressing the

key or applying a signal (rising edge only ). See the following table (section 11.3, column

„Acknowledge“).

Note: Always dispense at least two labels (pressing the key

) after occurrence of a

malfunction in order to ensure a correct label‘s position at the dispensing beak. If there

are optional print or control sy

stems present and active, as many labels must be

dispensed as there are between dispensing beak and the remotest unit.

Note: The elements of the SlimLine winder system (motorized unwinder, loop unwinder and

rewinder) have their own error codes, indicated via their illuminated push-button and

ex

plained in the corresponding sections. See also the error messages as of SM800.

Loading...

Loading...