4

Applicator description Operating instructions HERMA 400

30/154 3.28 US (130519)

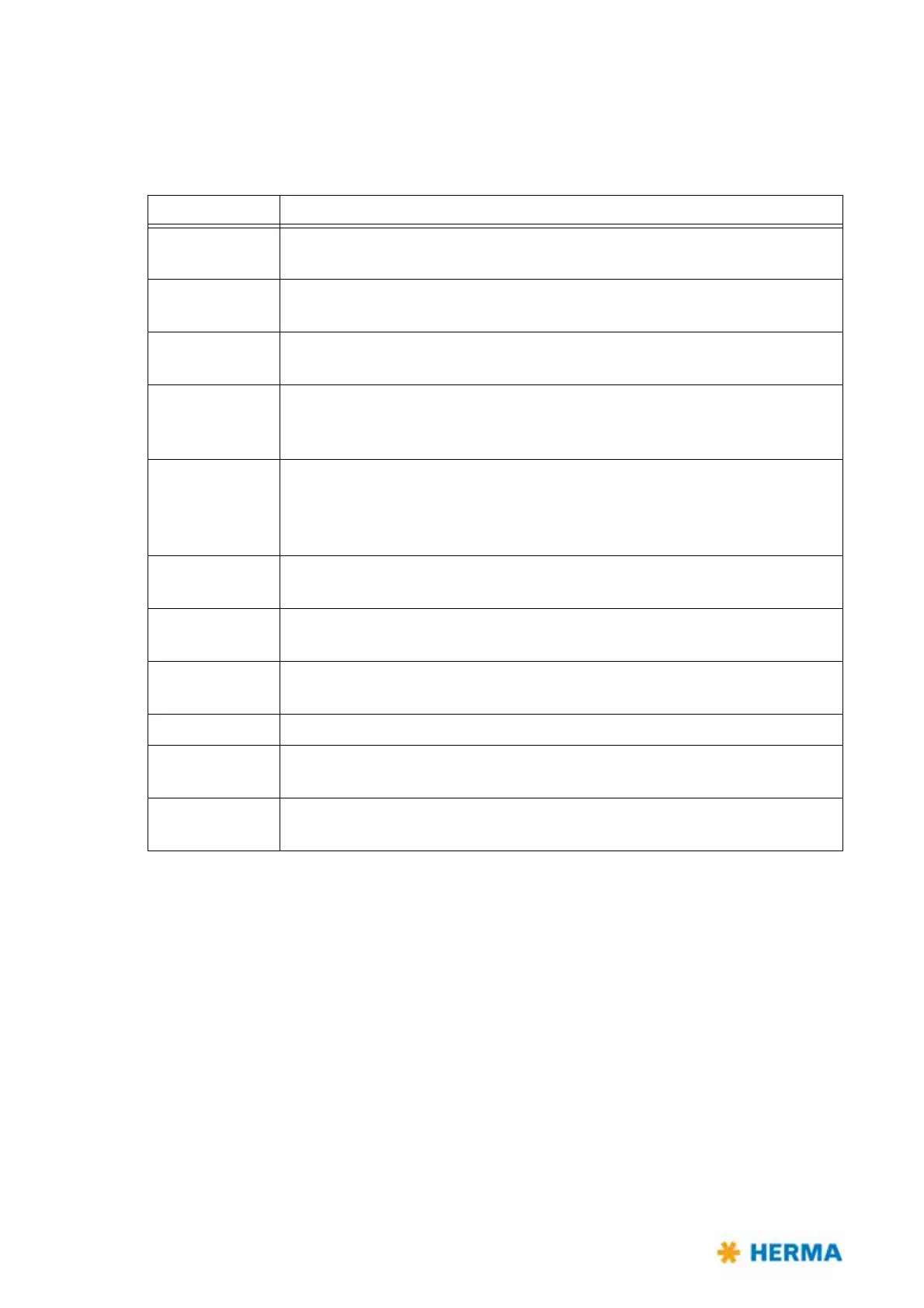

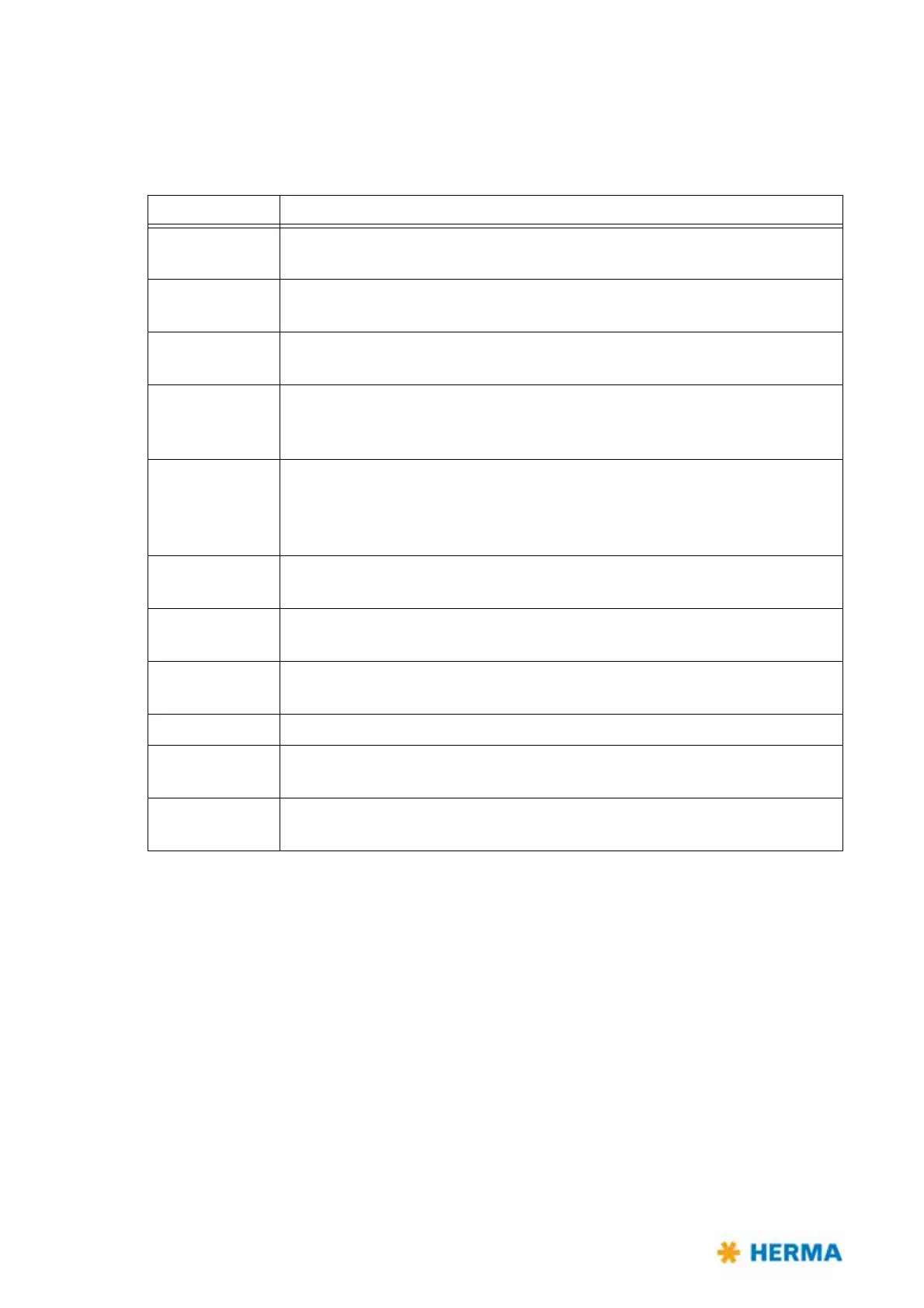

Error codes

Error codes, i.e,. blink codes, can be acknowledged and reset by pressing the illuminated button briefly.

The following codes may appear:

Blinking Cause

4x Unwinding without movement of pendulum (unwinder protection).

The pendulum remains in its position too long. Check parameters

958 and 959.

5x Measurement error which occurred e.g. on teaching the angle sensor (see

abov

e). Repeat teaching

6x Undefined error at unwinding unit with loo

p chute. Switch the unit off and then

on again.

7x Winding error at loop unwinder. Too much slip

page at the loop unwinder. Carry

out a visual inspection.

Check that mechanical parts are clean and function properly.

8x The pendulum rests in its max. deflected position too

long. Maybe the take-up

sleeve is not tensioned correctly, the web is used up but stuck to the take-up

sleeve, the motor is defective.

Increase the rotational speed.

Check parameters 950, 951, 954.

9x Low voltage power pack. Check the power supply, as the cas may be replace the

power pack.

10x Permanent overload of the drive, power consumption is too high. Check

parameters 950, 951,954.

11x Over temperature of the drive. Check

parameters 950, 951,954. Check that

mechanical parts are clean and function properly.

12x End of reel is signalled. Insert

a new label web.

13x Failed to determine diameter (only with CAN

connection). Check parameters

947, 948, 949.

14x Driver error issued. May be a hardware error in the in the power output stage. As

t

he case may be exchange the main board.

Loading...

Loading...