4.1 User Daily/Periodic Maintenance

According to the following table, please perform daily/periodic maintenance and replacement of parts by users.

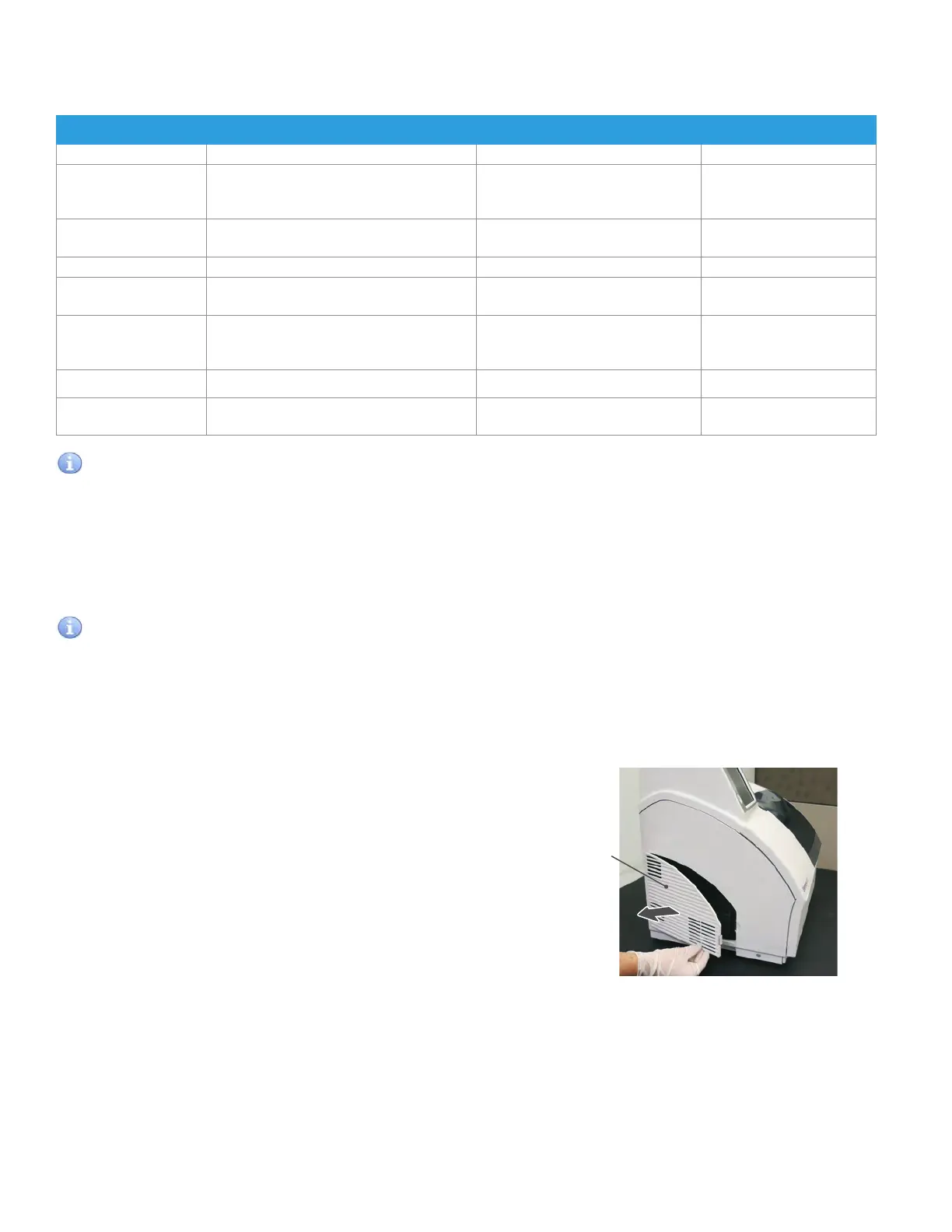

Check points Cleaning interval Replacement interval Procedure

Air filter Once a month - Refer to Section 4.2

Incubator Once every 3 months or

when inaccurate test

results occur

- Refer to Section 4.3

Spotting part When slide transfer error or tip ejection error

etc. occurs

- Refer to Section 4.3

Slide reader When reading errors occur frequently Refer to Section 4.4

Recording paper

-

Appearance of red lines (both sides

of paper)

Refer to Section 4.5

Light source lamp

-

When a photometer gain setting

error occurs, or the lamp’s cumulative

illumination time exceeds 1000 hours

Refer to Section 4.6

Sampler O-ring

- Once a year Refer to Section 4.7

ISE unit Once every 3 months or when inaccurate

test results occur

- Refer to Section 4.3

IMPORTANT

After maintenance, plug in the AC power cable, and be sure to check the operation of the analyzer by turning on the

power switch.

4.2 Cleaning the Air Filters

The air filter should be checked and cleaned at least once a month.

IMPORTANT

If the air filter is not cleaned, the temperature inside the analyzer will increase resulting in adverse effects on test

results.

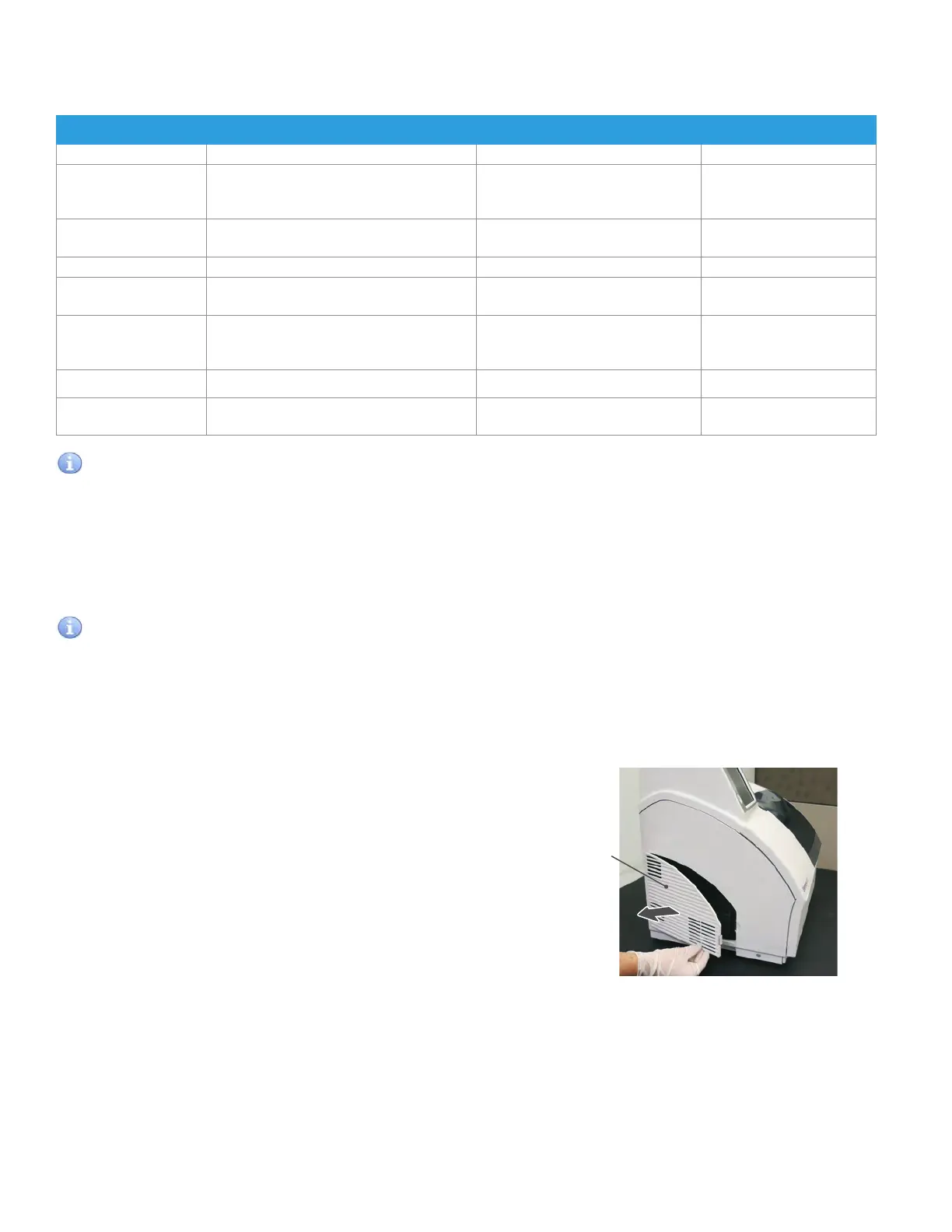

Louver

4.2.1 Cleaning procedures

1. Turn off the power of the Element DC.

2. Remove the louver, and then take out the air filter.

48

Loading...

Loading...