IS810N-INT Series Servo System User Manual (Brief) Chapter 7 Troubleshooting

- 248 -

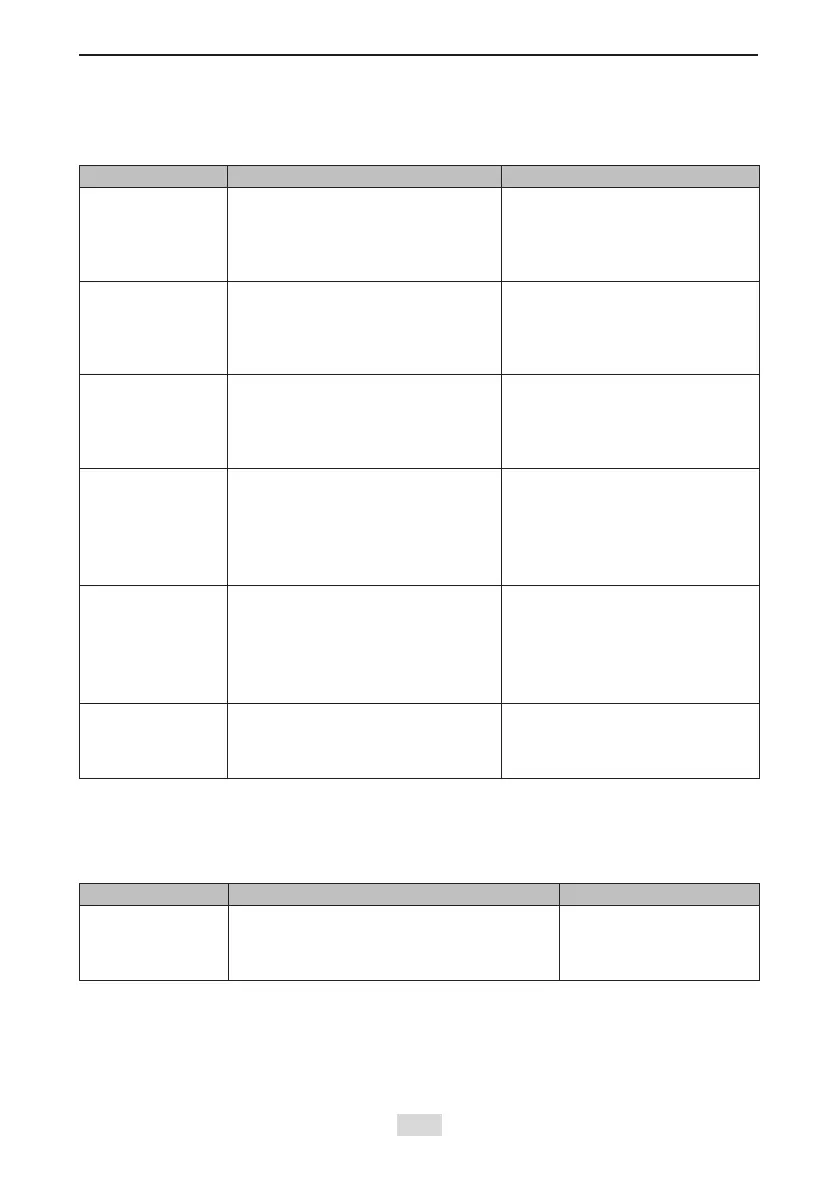

E1.B01: abnormal position reference increment

Cause:

The target position increment in CSP mode is too large.

Probable Cause Conrming Method Corrective Action

1. The position

reference

increment is too

large.

Check the target position increment

of the adjacent synchronization

cycles.

Decrease the position reference

speed, or set a certain

acceleration/deceleration curve

when the host controller plans the

target position.

2. Before switching

modes, the target

position is not

aligned with the

current position.

Check whether mode switching

happened in the controller software.

Before mode switching, assign the

value of the current position to the

target position.

3. When the servo

is enabled, the

target position is

not aligned with the

current position.

Check whether the operation of

enabling the servo happened in the

controller software.

When the servo is enabled, assign

the value of the current position to

the target position.

4: The target

position value is

abnormal.

After the soft limit function is used,

the target position overows near

231-1 or -231.

After any hardware limit signal is

valid, the target position overows

near 231-1 or -231.

When the soft limit function or

hardware limit signal is valid, the

target position must be limited

between [-231, 231-1].

5. The gear

ratio setting is

unreasonable.

Check whether the 6091-01h and

6091-02h are set incorrectly.

Check whether scaling factors of

the host controller associated with

machine and motor encoder are set

incorrectly.

Modify gear ratio and host

controller related scaling factors

according to practical applications.

6. Motor selection

is unreasonable.

Check whether the maximum motor

speed is less than the maximum

operating speed that satises on-site

demand.

Re-select the motor or reduce the

maximum operating speed on site.

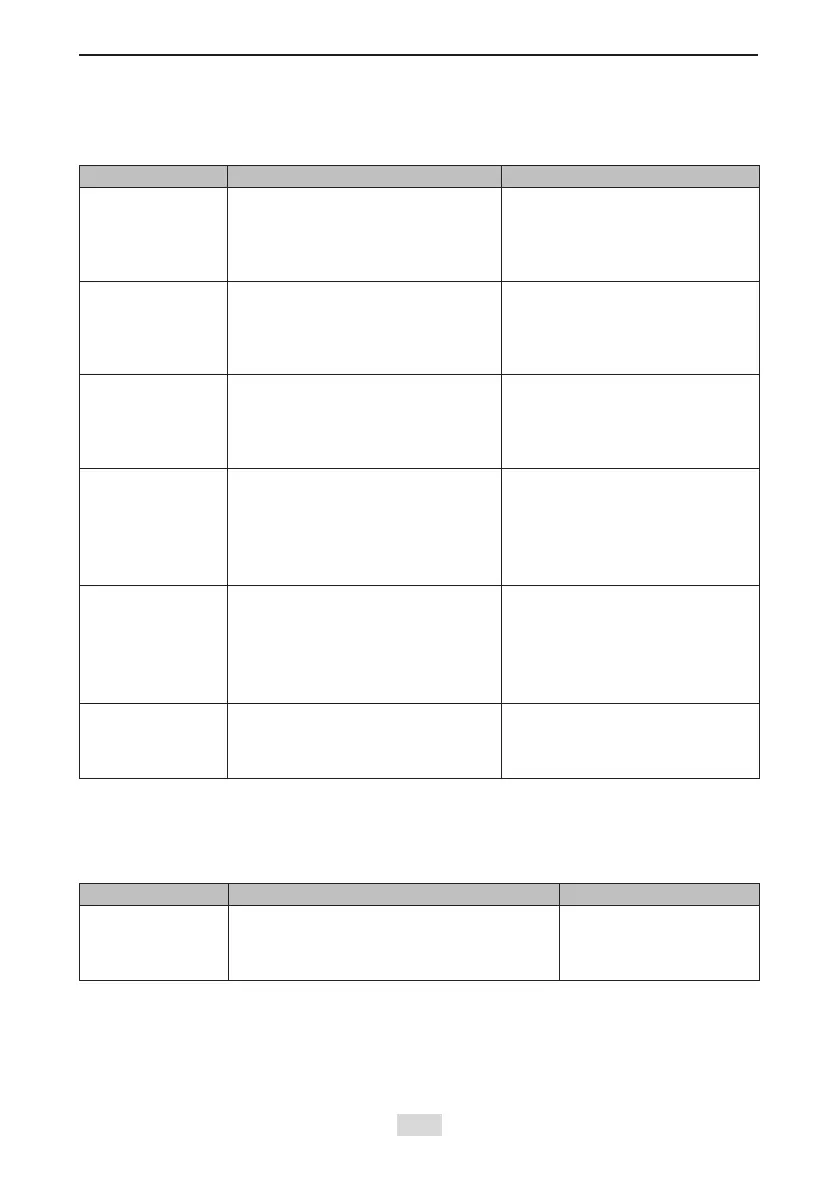

E1.B03: Electronic gear ratio setting exceeds limit

Cause:

Electronic gear ratio exceeds limit: (0.001 x encoder resolution/10,000, 4,000 x encoder

resolution/10,000).

Probable Cause Conrming Method Corrective Action

1. The electronic

gear ratio setting

exceeds the

preceding range.

Check whether the ratio value of

6091-01h/6091-02h exceeds the preceding

range.

Set the gear ratio within

the required range.

Loading...

Loading...