IS810N-INT Series Servo System User Manual (Brief)

- 2 -

Preface

Preface

Thank you for purchasing the IS810N-INT series servo drive.

The IS810N-INT series is a high-performance AC servo drive for small and medium power

applications. The power of the IS810N-INT series ranges from 100 W to 75 kW. It supports

MODBUS, CANopen, and CANlink communication protocols, which allows networking of multiple

IS810N-INT drives controlled by a host controller via the corresponding communication port. The

IS810N-INT is easy to use due to the functions of stiffness table setting, inertia auto-tuning and

vibration suppression. It works together with Inovance ISMH series small/medium-inertia high-

response servo motor congured with a 20-bit incremental encoder or 23-bit multi-turn absolute

encoder, making running stable and quiet and positioning control more accurate. This servo drive

is able to implement rapid and accurate position, speed, and torque control, and is applicable

for such automation equipment as gravure press machines, exo printing machines, corrugated

paper printing equipment, semiconductor manufacturing equipment, chip mounters, PCB punching

machines, transport machinery, food processing machinery, machine tools and conveying machinery.

This User Guide describes how to use the IS810N-INT series servo drive, covering safety

information, mechanical and electrical installation, commissioning and maintenance. Read

and understand this User Guide before use. If you have doubts about some functions or

performance, contact the technical support personnel of Inovance.

The instructions in this User Guide are subject to change without notice due to product upgrade,

specication modication, as well as efforts to increase the accuracy and convenience of the

User Guide.

Authorised distributors shall deliver this User Guide a long with equipment to end users.

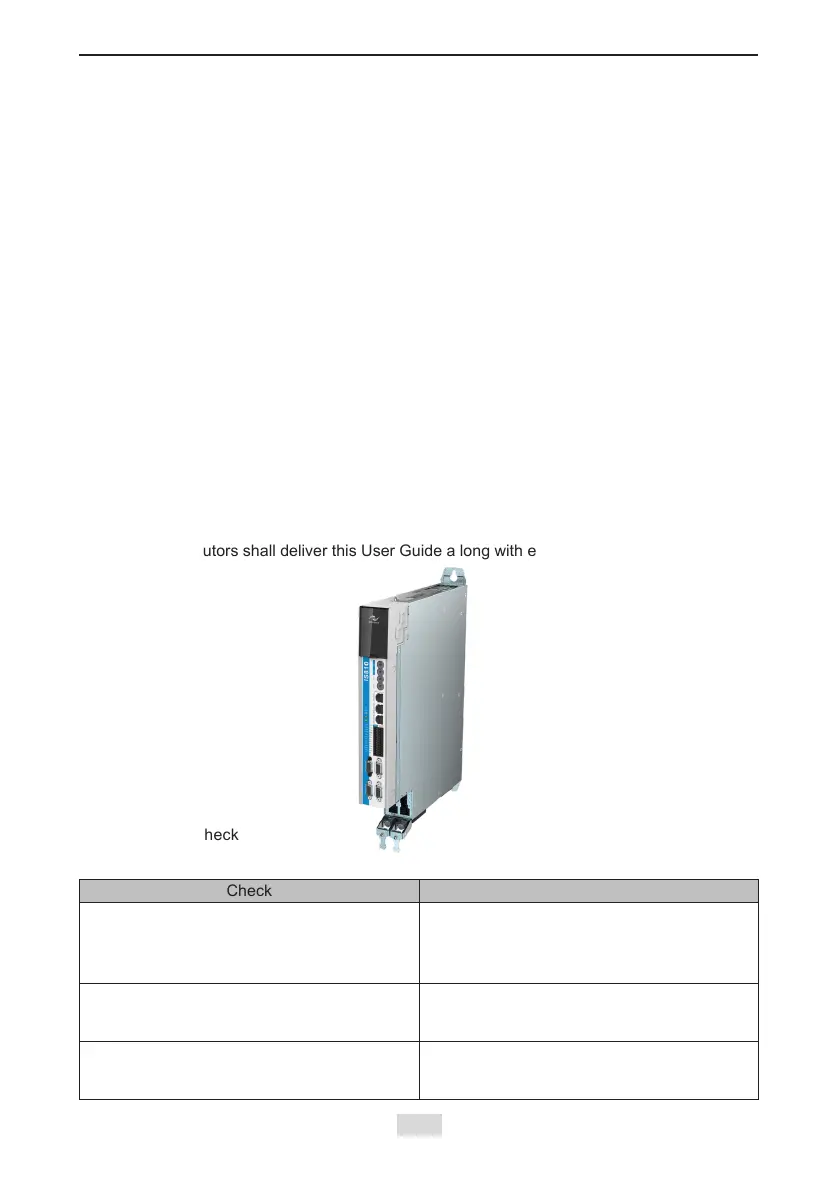

Unpacking and Check

Upon unpacking:

Check Description

Whether the delivered product is consistent

with your order

The box contains the equipment, and the

IS810N User Guide.

Verify the model according to the servo motor

and servo drive nameplates.

Whether the product is damaged Check the appearance of the product. If there

is anything missing or damaged, contact

Inovance or your supplier immediately.

Whether the rotating shaft of the servo motor

rotates smoothly

Normally, the shaft of the servo motor can be

rotated manually, unless the servo motor is

congured with a brake.

Loading...

Loading...