IS810N-INT Series Servo System User Manual (Brief)Chapter 3 Installation

- 67 -

3.3 Servo Motor Installation

3.3.1 Installation Precautions

Install the servo drive in an environment free from corrosive or inammable gas or combustible

goods, such as hydrogen sulde, chlorine, ammonia, sulphur gas, chlorinated gas, acid, soda

and salt;

Use a servo motor with an oil seal when the motor is to be used in a place with grinding uid,

oil spray, iron powder, or cuttings;

Keep the servo motor away from heat sources such as a heating stove;

Do not use the servo motor in an enclosed environment. Working in the enclosed environment

will lead to high temperature of the servo motor, which will shorten its service life.

Table 3-2 Installation precautions

Item Description

Rust-proof treatment

Wipe up the antirust agent at the motor shaft extension before installing

the servo motor, and then apply rust-proof treatment.

Encoder

u

Prevent shaft extension impact during installation. Failure to comply

will lead to damages to the internal encoder.

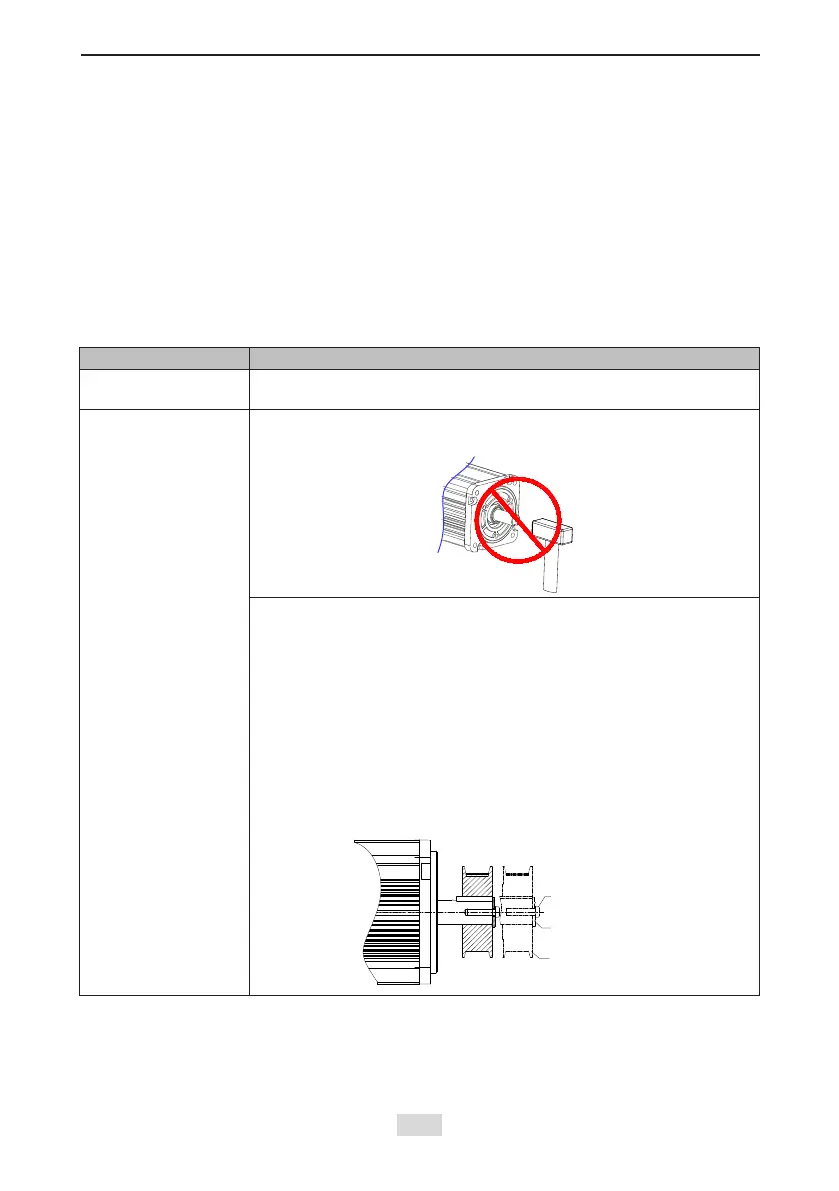

u

Use the screw hole at the shaft end to mount a pulley to the servo

motor shaft with a keyway. To t the pulley, insert a double-end

screw into the screw hole of the shaft, put a washer against the

coupling end, and then use a nut to push the pulley in.

u

If there is a keyway on the servo motor shaft, mount the pulley by

using the screw holes at the axle head. For the servo motor shaft

without a keyway, use friction coupling or other similar installation

methods.

u

When removing the pulley, use a pulley remover to protect the shaft

against damages from the load.

u

To ensure safety, install a protective cover or similar device on the

rotary part such as the pulley mounted on the shaft.

Flange coupling,

pulley

Washer

Screw

Loading...

Loading...