IS810N-INT Series Servo System User Manual (Brief) Chapter 3 Installation

- 68 -

Item Description

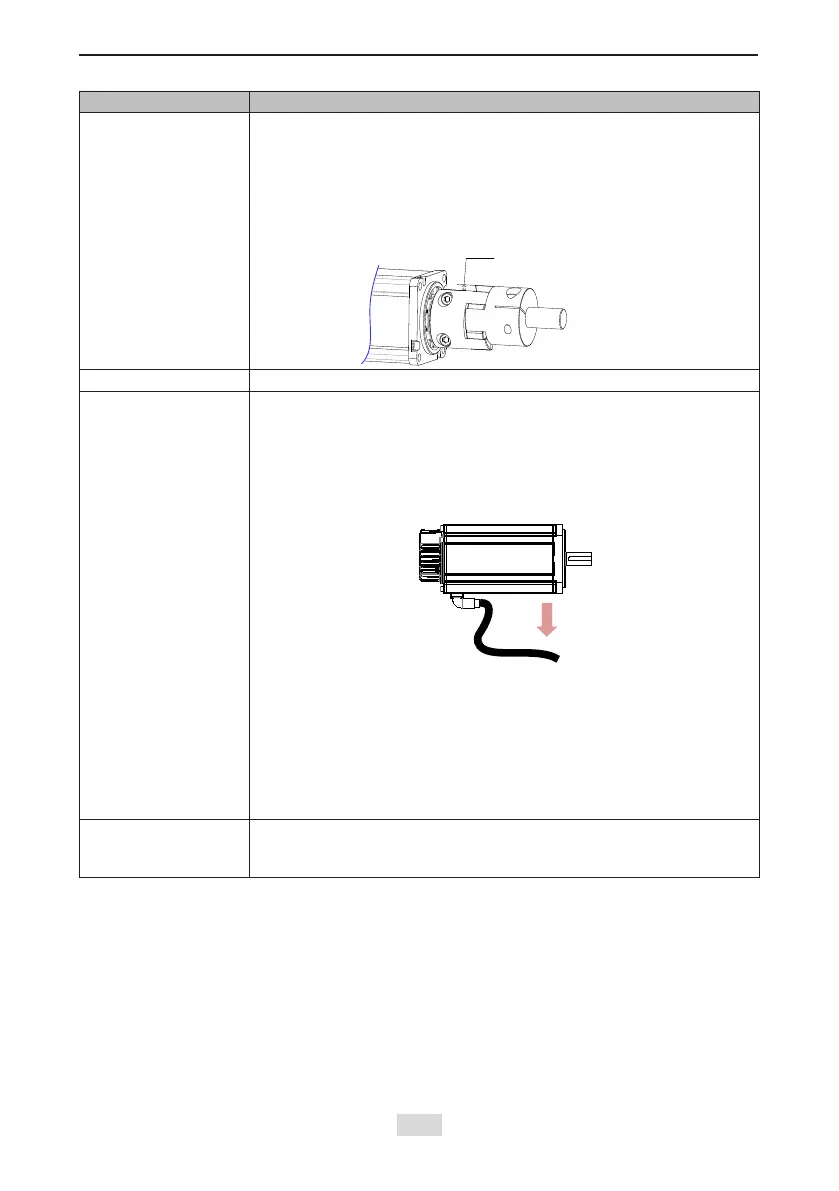

Alignment

u

Use the shaft coupling for mechanical connection and align the axis

of the servo motor with the axis of the equipment. When installing

the servo motor, make sure that alignment accuracy satises the

requirements as described in the gure to the left. If the axes are

not properly aligned, vibration will be generated and may damage

the bearings and encoder.

Measure the distance at four different

positions on the circumference. The

difference between the maximum and

minimum measurements must be 0.03 mm

or less.

Installation direction

u

The servo motor can be installed horizontally or vertically.

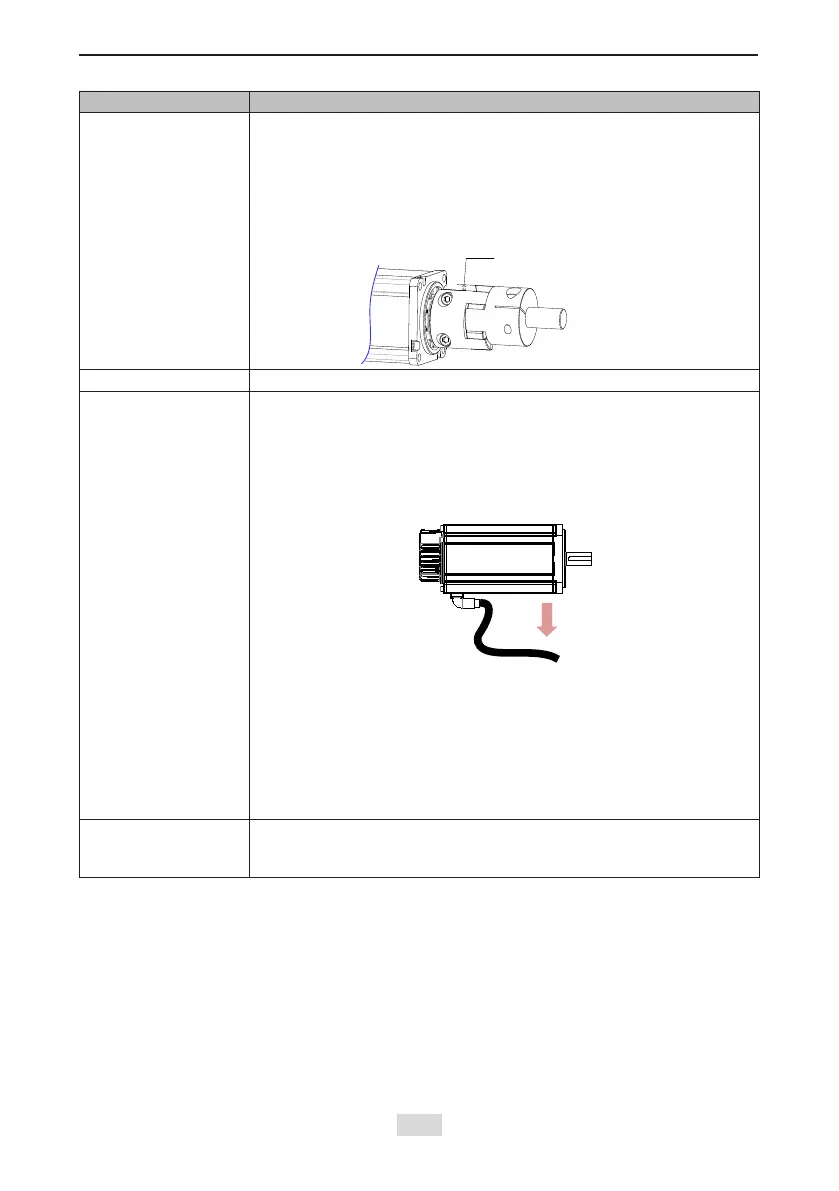

Oil and moisture

countermeasures

1) Do not immerse the servo motor and cables into oil or water during

use.

2) Conrm the IP class of the servo motor when using it in a place with

water drops (Except the shaft-through portion)

3) Mount the motor with the cable outlet facing downwards to prevent

water/oil from owing into the motor (as shown in the following gure).

4) In the environment where the shaft-through portion is exposed to oil

drops, use a servo motor with oil sealing.

5) Observe the following conditions when using the servo motor with oil

sealing:

Make sure that the oil level is lower than the oil seal lip during use;

Avoid oil accumulation at the oil seal lip when the motor is installed

vertically upward.

Stress of cables

u

Do not bend or apply tension to the cables, especially the signal

cables whose core wire is 0.2 or 0.3 mm in diameter. Do not exert

too much tension on the cables during wiring.

Loading...

Loading...