IS810N-INT Series Servo System User Manual (Brief) Chapter 7 Troubleshooting

- 250 -

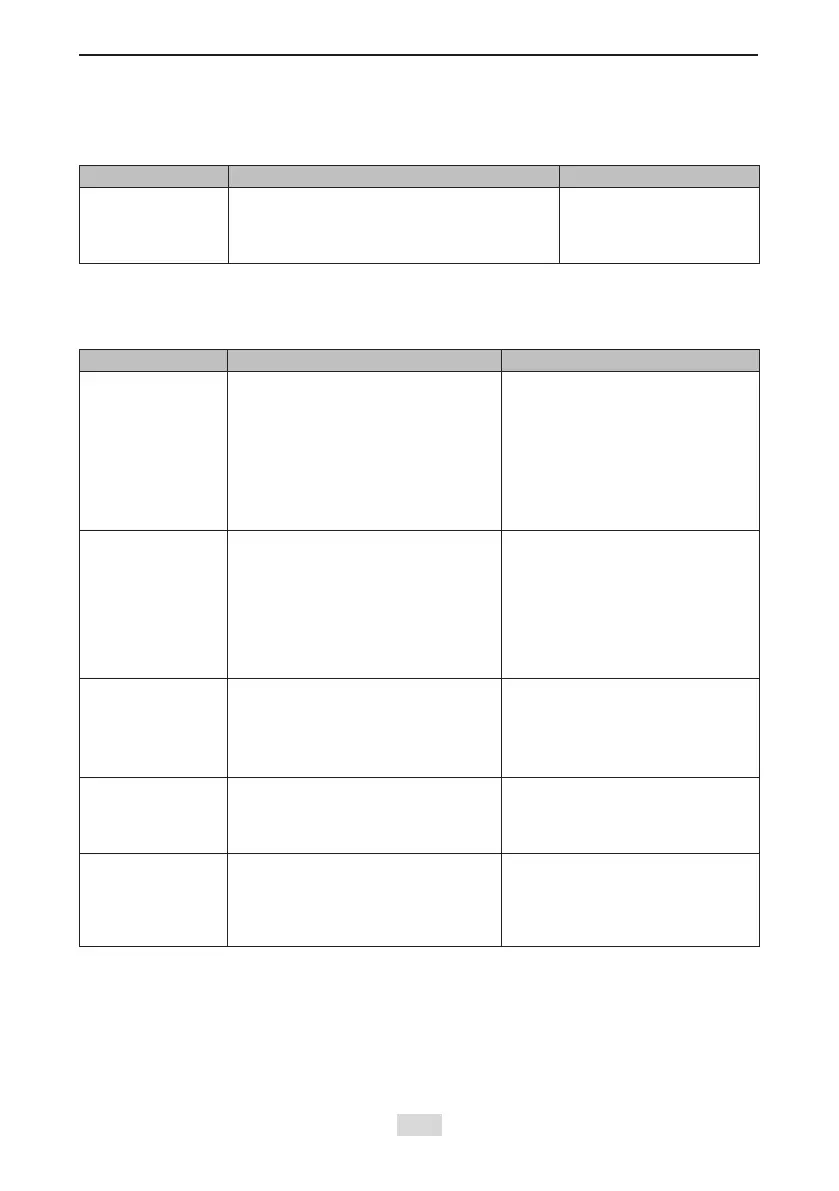

E1.730: Encoder battery alarm

Cause:

The battery voltage of the absolute encoder is lower than 3.0 V.

Probable Cause Conrming Method Corrective Action

The battery voltage

of the absolute

encoder is lower

than 3.0 V.

Measure the battery voltage.

Use a new battery with the

matching voltage.

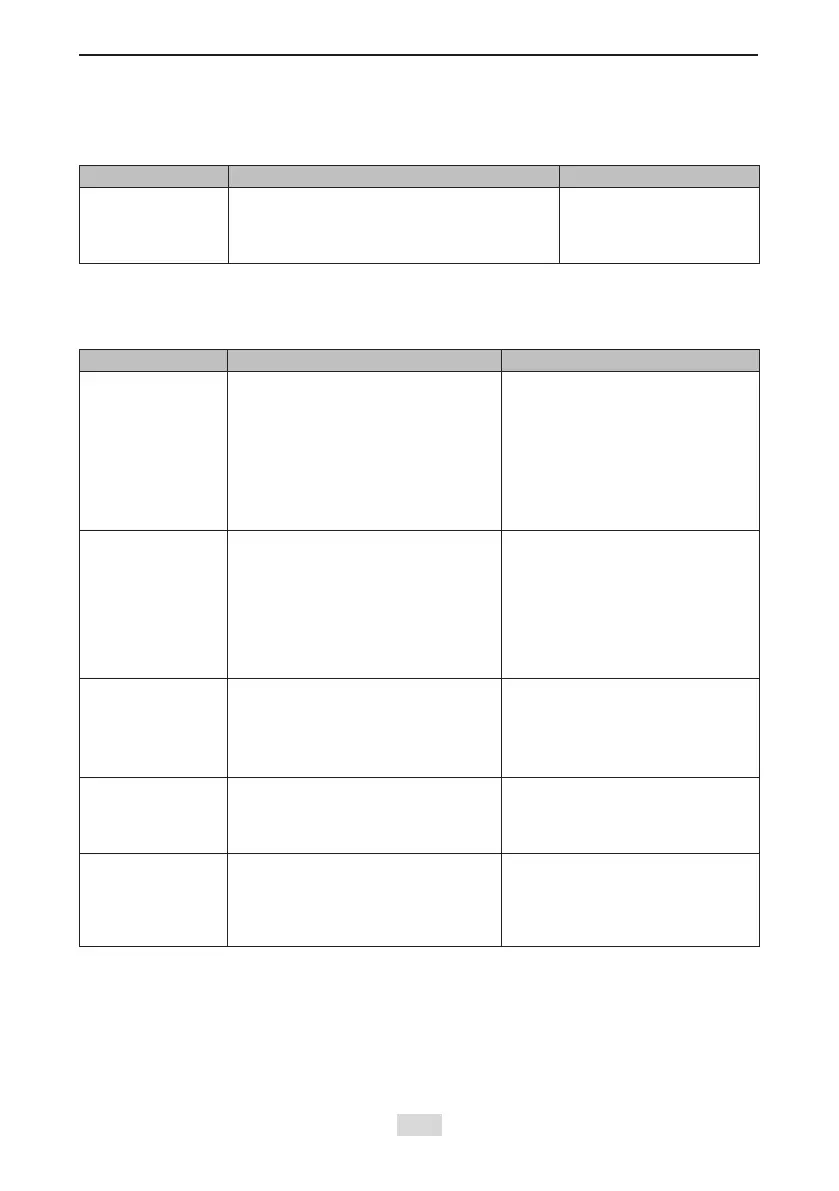

E1.909: Motor overload warning

Cause:

Accumulative heat of 60Z series 200 W and 400 W motors reaches the warning threshold.

Probable Cause Conrming Method Corrective Action

1. Wiring of the

motor and encoder

is incorrect or in

poor contact.

Check the wiring between the servo

drive, servo motor and the encoder

according to the correct wiring

diagram.

Connect the wirings according to

the correct wiring diagram.

Preferably use the cables

recommended by Inovance.

When self-made cables are used,

prepare and connect the cables

according to the hardware wiring

instructions.

2. The load is too

heavy. The motor

keeps output of

effective torque

higher than the

rated torque for

a continuous

operation.

Conrm the overload characteristics

of the servo drive or servo motor.

Check whether the average load

ratio (200B-0Dh) exceeds 100.0%

for a long time.

Use a servo drive of larger capacity

and matching servo motor.

Reduce the load and increase the

acceleration/deceleration time.

3. Acceleration/

deceleration is too

frequent or the load

inertia is too large.

Check the mechanical inertia ratio or

perform the inertia auto-tuning. Then

view 2008-10h (load inertia ratio).

Check the single running cycle when

the servo motor runs circularly.

Increase the acceleration/

deceleration time.

4. The gain is

improper, or the

stiffness is too

high.

Check whether the motor vibrates

and produces abnormal noise during

running.

Re-adjust the gain.

5. The servo drive

or motor model is

set incorrectly.

View the bus motor model in

2000-06h and servo drive model in

2001-0Bh.

View the servo drive nameplate

and set the servo drive model

in 2001-0Bh correctly and use a

matching servo motor according to

Section 2.3.

Loading...

Loading...