SECTION 12—CASTERS, FORK AND FORK STEM ASSEMBLIES

Part No 1125104 81 ProSPIN™ X4™

Adjusting Fork Tension

NOTE:Forthisprocedure,refertoFIGURE12.3.

1. Toproperlytightenforksandguardagainstflutter,performthefollowingcheckon

bothforks:

A. Tipbackthewheelchairtofloor.

B. Pivotbothforksandcasterstotopoftheirarcsimultaneously.

C. Letcastersdroptobottomofarc(wheelsshouldswingoncetoone‐side,then

immediatelyrestinastraightdownwardposition).

2. Ifnecessary,performoneofthefollowingtoadjusttheforktension:

• StandardForks‐Adjustlocknutaccordingtofreedomofcasterswing

(Detail“A”).

•SuspensionFork(Detail“B”)‐

a. RefertoRemovingtheElastomeronpage 86toremovetheelastomerand

suspensionforkbottomtoaccessthelocknut.

b. Adjustlocknutaccordingtofreedomofcasterswing.

c. RefertoInstallingtheElastomeronpage 86tosecurethesuspensionforktop

totheelastomerandsuspensionforkbottom.

3. Testwheelchairformaneuverability.

4. Ifnecessary,repeatSTEPS1‐2toadjustlocknutsuntiltensioniscorrectforbothforks.

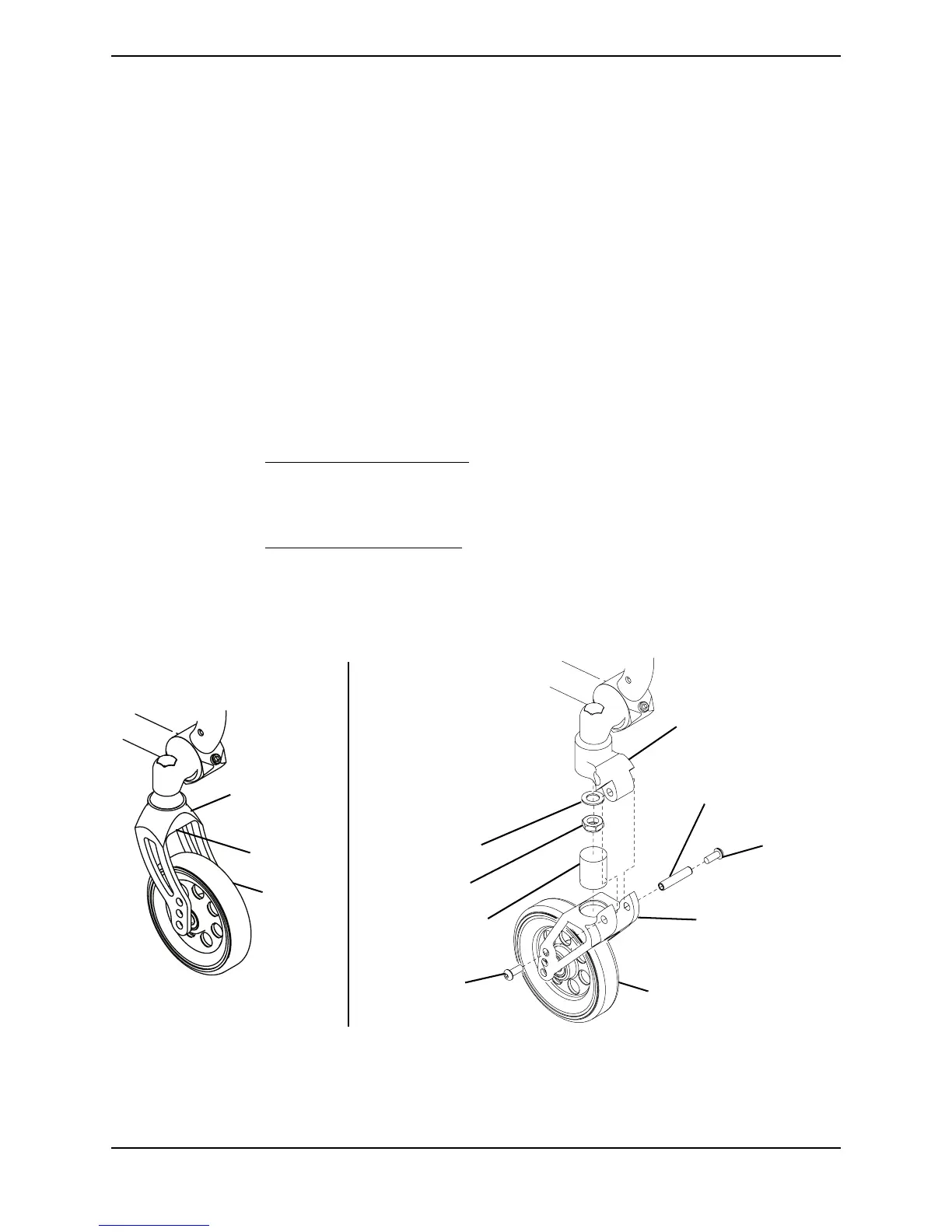

FIGURE 12.3 Adjusting Fork Tension

Fork

Locknut

Caster

DETAIL “B”

SUSPENSION FORK

Suspension Fork Top

Washer

Locknut

Suspension

Fork Bottom

Elastomer

Threaded Bushing

Mounting

Screws

Mounting

Screws

DETAIL “A”

STANDARD FORK

Caster

NOTE:Washerand

locknutshownexploded

forclarityonly.DO

NOTremove.

Loading...

Loading...