Risk of burns from hot components and escaping oil!

➤ Wear long-sleeved clothing and protective gloves.

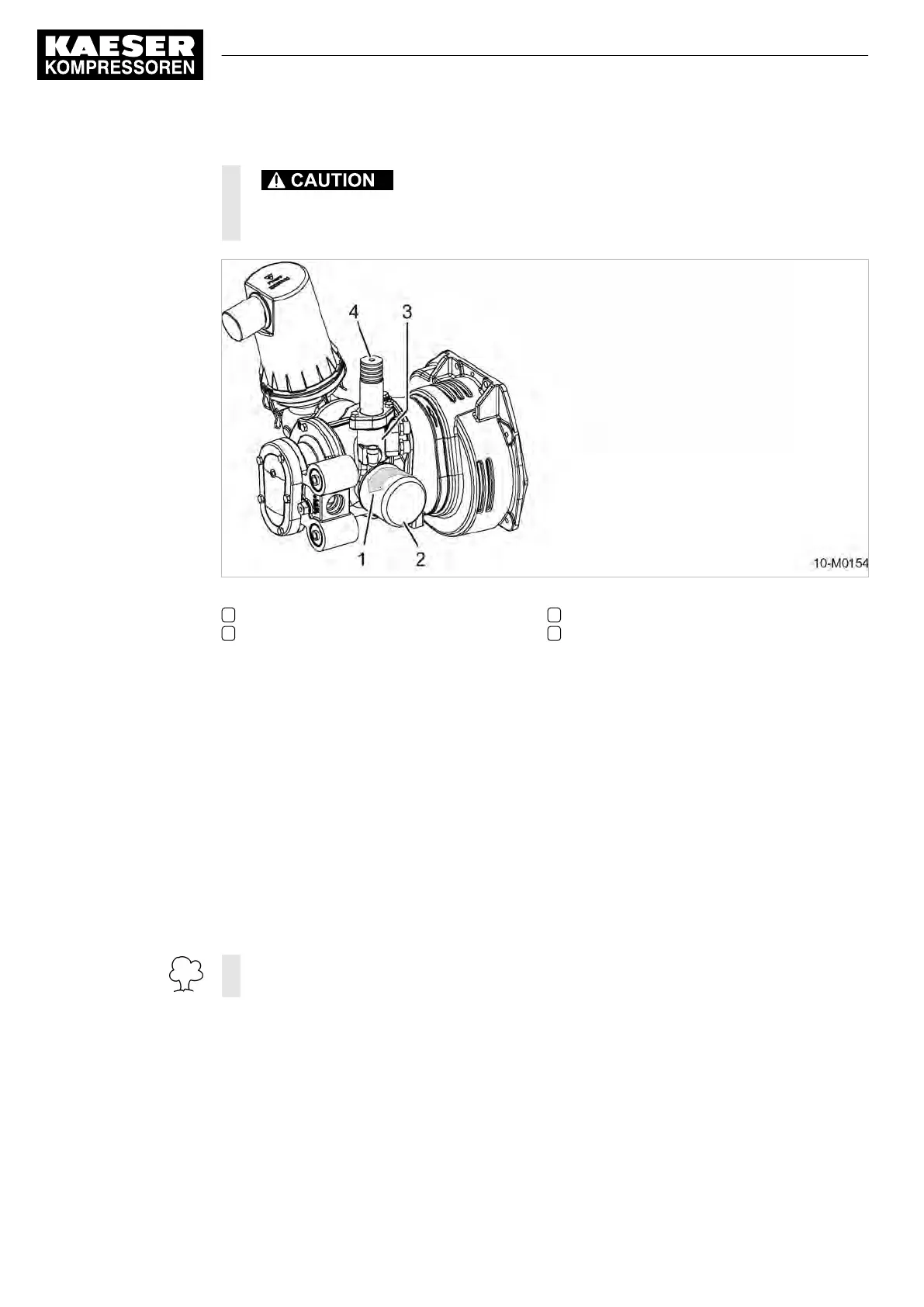

Fig. 52 Changing the oil filter

1 Oil filter

2 Direction of rotation to unscrew the oil fil‐

ter.

3 Combination valve (integrated into airend)

4 Ambient temperature reading

Changing the oil filter

1.

Open the canopy.

2. Prepare a receptacle.

3. Loosen the filter by turning counterclockwise and catch any escaping oil.

4. Carefully clean sealing surfaces using lint-free cloth.

5. Lightly oil the new filter's gasket.

6. Turn the oil filter clockwise by hand to tighten.

7. Check the oil level in the oil separator tank.

Top up if necessary.

8. Reconnect the negative battery terminal.

9. Close the canopy.

Dispose of old cooling oil and any materials or parts contaminated with oil according to envi‐

ronmental protection regulations.

Starting the machine and performing a test run:

1.

Start the machine and run in IDLE until the operating temperature is reached.

2. Close the outlet valves.

3. Shut down the machine.

4. Wait until the machine has automatically vented.

Pressure gauge reads 0 psig!

10 Maintenance

10.4 Compressor Maintenance

134

Operator Manual Screw Compressor

M27

No.: 9_9548 05 USE

Loading...

Loading...