10.8.6 Option ga

Generator drive belt maintenance

Correct belt tension is extremely important for the function of the generator and the operational life

of the belt itself.

Use a tensioning mechanism with a spring strut, swing frame and tension pulley to ensure correct

belt tensioning. The spring force pushes downward the swing frame with tensioned pulley between

the pulley of the crankshaft and the pulley of the generator of the belt drive and thus generates the

required belt tension.

Material Ratchet 1/2 inch

Spare parts (if required)

Precondition The machine is shut down.

The machine is fully vented, the pressure gauge reads 0 psig.

The machine is cooled down.

All compressed air consumers are disconnected and the air outlet valves are open.

Beware of rotating pulleys and moving belts.

Touching the moving drive belt may result in severe bruising or even loss of limb or extremi‐

ties.

➤ Check the belt only when the compressor is shut down.

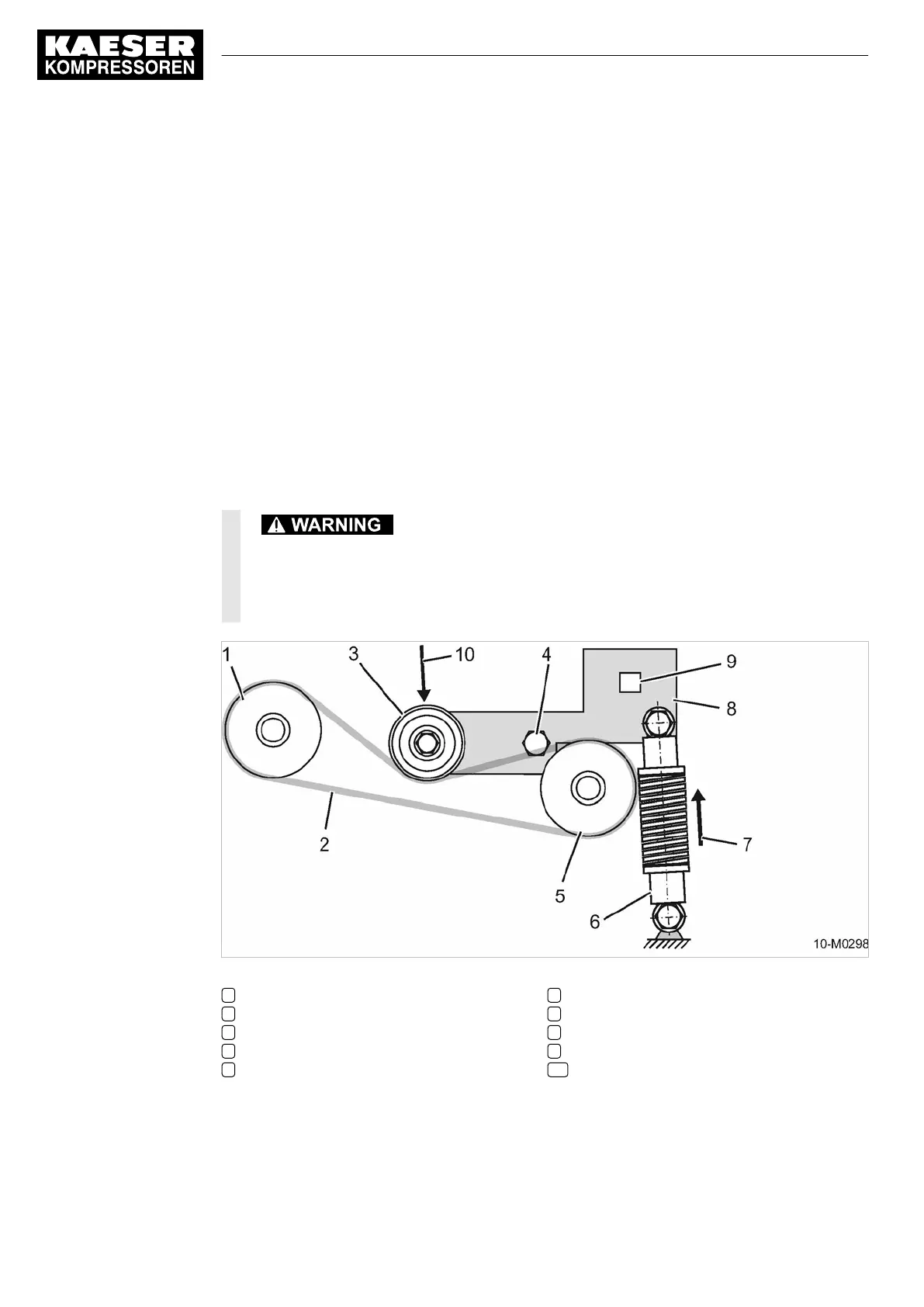

Fig. 71 Replacing the generator belt

1 Pulley, crankshaft

2 Drive belt

3 Tension pulley

4 Deviation point, swing frame

5 Generator drive pulley

6 Spring strut

7 Spring force F1

8 Tensioning frame

9 Square socket: 1/2 inch

10 Leverage F2

➤ Comply with the safety instructions in chapter 3.5.

10 Maintenance

10.8 Maintenance for Optional Items

162

Operator Manual Screw Compressor

M27

No.: 9_9548 05 USE

Loading...

Loading...