Material See chapter 10.4.3 for oil filling volume.

Receptacle

Hose coupling is disconnectedly laying at the machine.

Funnel

Cleaning cloth

Precondition The machine is shut down.

The machine is standing level.

The machine is fully vented, the pressure gauge reads 0 psig.

The machine is at operating temperature.

All compressed air consumers are disconnected and the air outlet valves are open.

The negative cable to the battery is disconnected.

Risk of burns from hot components and escaping oil!

➤ Wear long-sleeved clothing and protective gloves.

➤ Open the cover.

10.4.3.1 Draining the cooling oil

All cooling oil is drained via the oil discharge valve. The oil discharge valve is positioned on the

airend and closed with a sealing cap to prevent contamination. This sealing cap must removed pri‐

or to draining the oil.

The oil can be drained when the hose nozzle has been screwed onto the oil discharge valve.

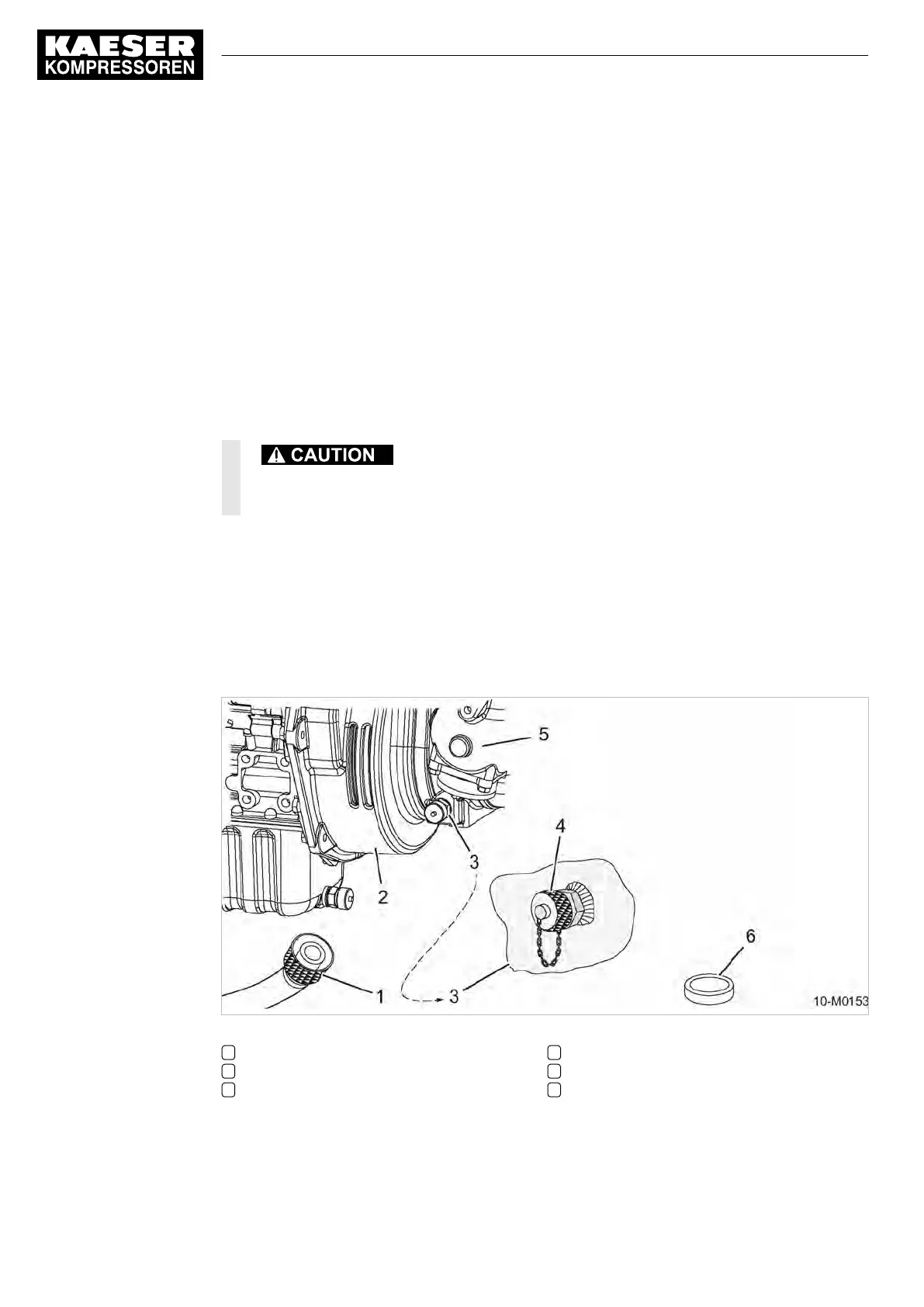

Fig. 51 Draining the compressor cooling oil

1 Hose coupling

2 Airend

3 Oil drain valve

4 Protective cap

5 Inlet valve

6 Bung (Option oe)

10 Maintenance

10.4 Compressor Maintenance

132

Operator Manual Screw Compressor

M27

No.: 9_9548 05 USE

Loading...

Loading...