12.2.3.2 Option rb/rm/rs

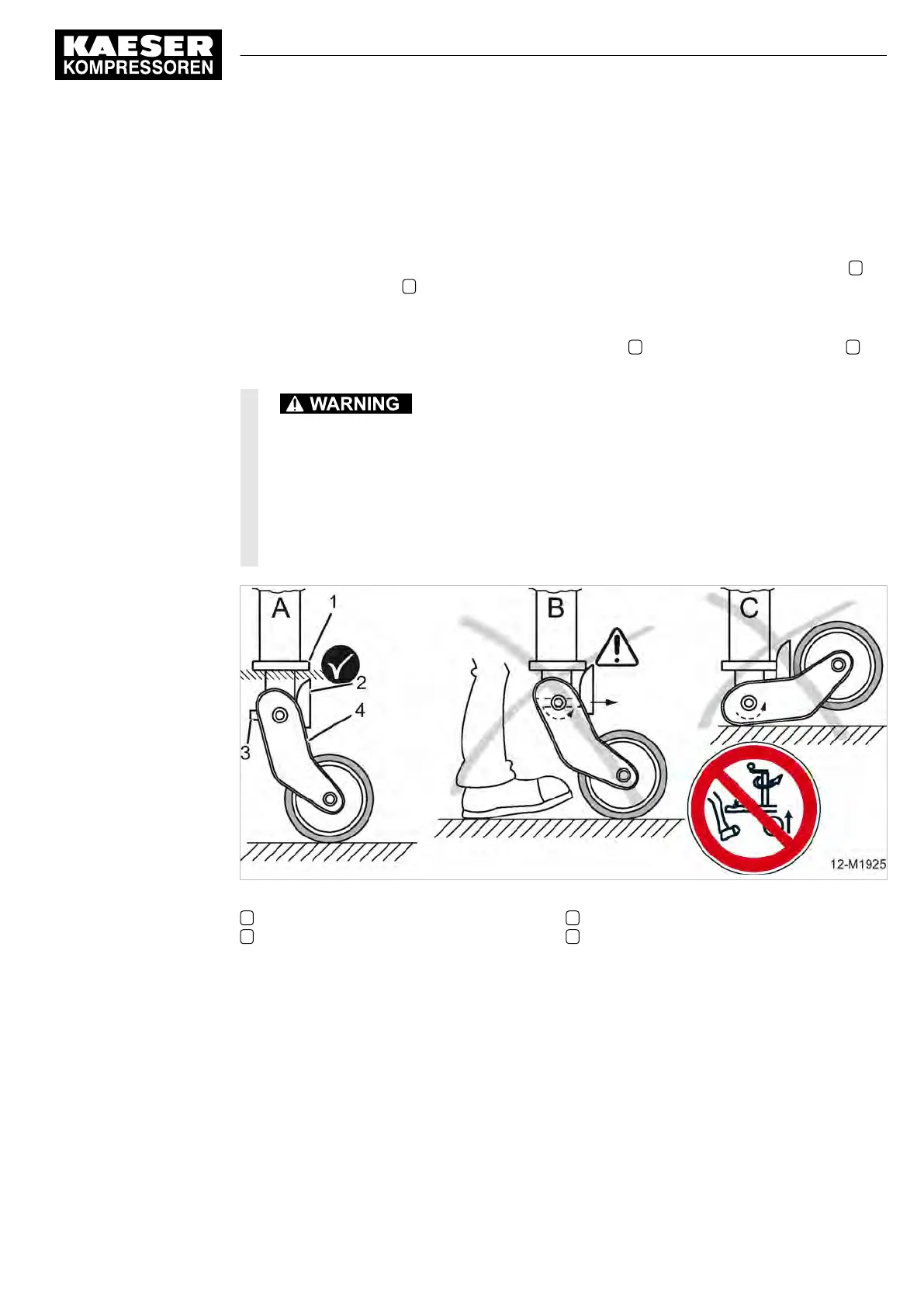

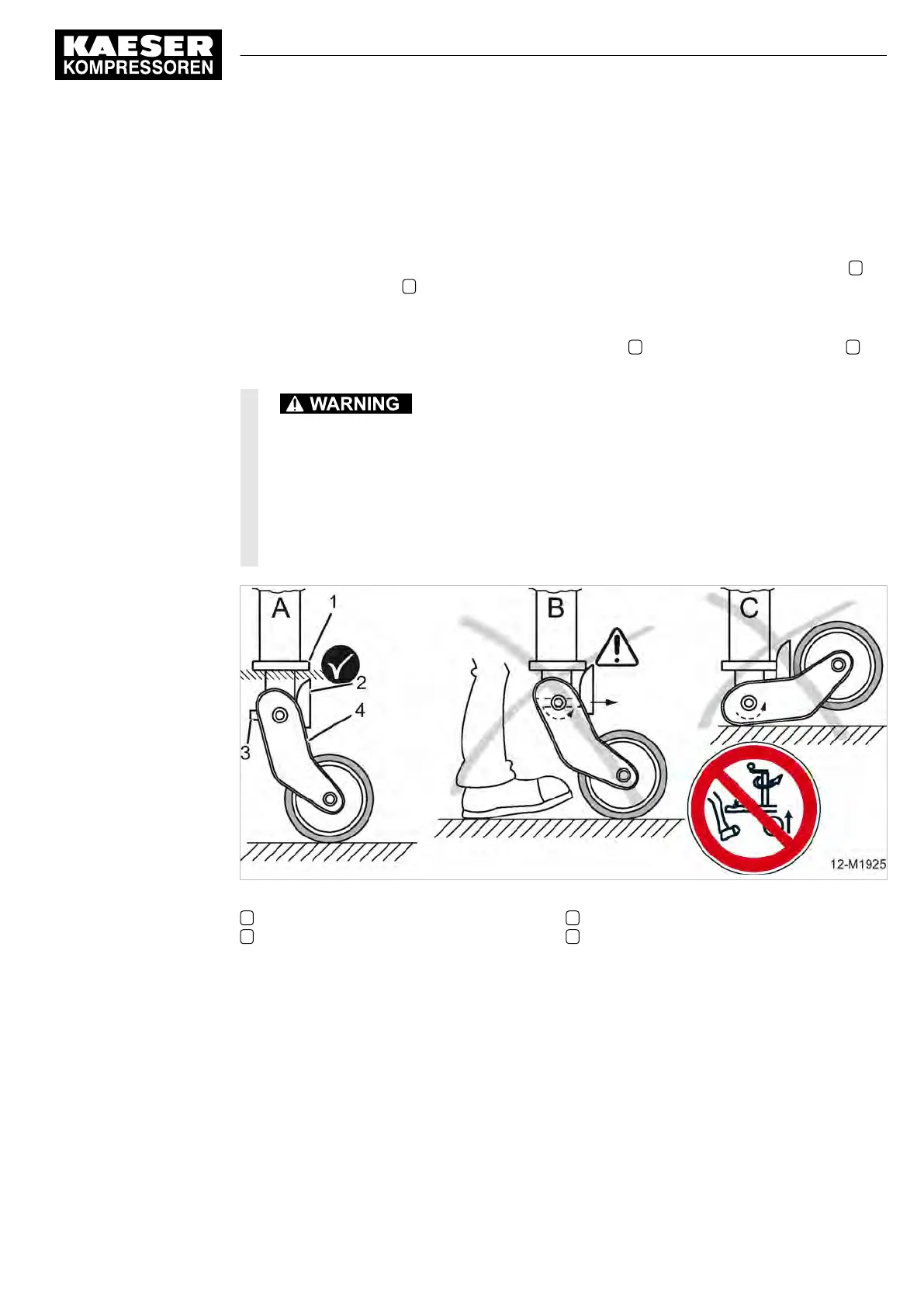

Parking a machine with a height-adjustable chassis and automatic jockey wheel

In a parked machine which is separated from the towing vehicle, the machine's bearing load affects

the automatic jockey wheel.

For this reason, the jockey wheel of a separated machine must be wound down until the cam 2 no

longer touches the bead 1 . The automatic folding of the wheel suspension is thus blocked (see

figure 82

/A).

When the jockey wheel of a separated machine is wound up further, the bead pushes against the

cam of the retaining pin (see figure 82/B). The retaining pin 3

unlocks the wheel suspension 4

which will abruptly fold (see figure 82/C).

A folding wheel suspension during winding up causes the towing device to suddenly crash

onto the ground,

potentially causing severe injuries to legs and/or feet.

➤ Wind the automatic jockey wheel only up when the machine is coupled to a towing vehi‐

cle.

➤ Wind the automatic jockey wheel up only as far as the bead does not touch the cam.

➤ Do not place your feet beneath the towing device.

Fig. 82 Warning: Risk of injury due to falling towing device!

1 Bead

2 Cam

3 Retaining pin

4 Wheel suspension

1. Use a coupled towing vehicle to move the machine into position.

2.

Place chocks under the wheels.

3. Loosen the lighting and signalling system.

4. Pull on the parking brake past the dead point zone (see figure 81).

The gas spring holds the brake under tension.

5. Detach the breakaway cable.

6. Lower the jockey wheel.

7. Pull the coupling handle up and lower the jockey wheel further.

The ball coupling must be released from the towing device of the towing vehicle.

12 Decommissioning, Storage and Transport

12.2 Transport

No.: 9_9548 05 USE

Operator Manual Screw Compressor

M27

227

Loading...

Loading...