10.8.1 Option ea

Tool lubricator maintenance

Material Tool oil (special lubricant for road breakers)

Funnel

Cleaning cloth

Precondition The machine is shut down.

The machine is standing level.

The machine is fully vented, the pressure gauge reads 0 psig.

The machine is cooled down.

All compressed air consumers are disconnected and the air outlet valves are open.

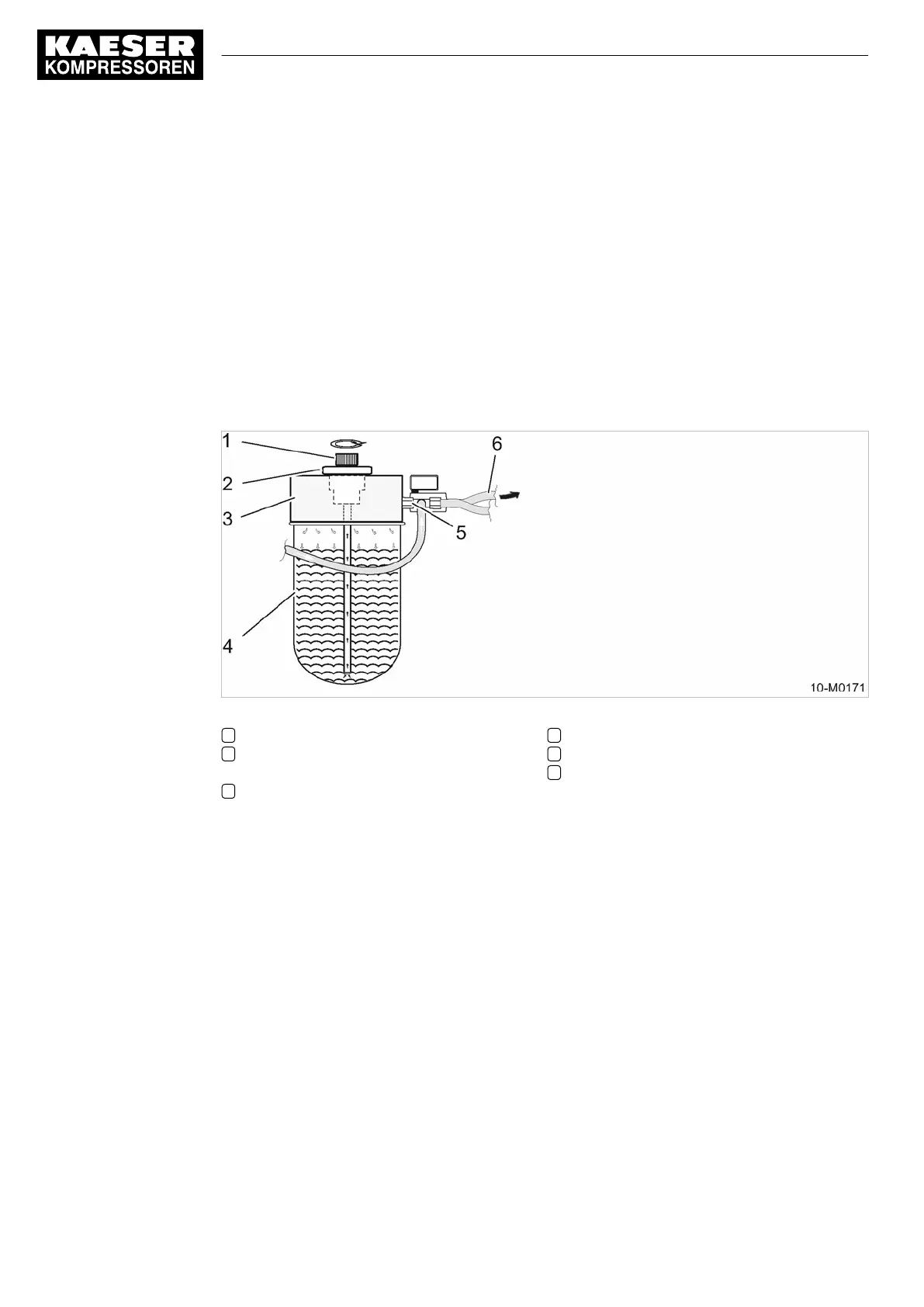

Fig. 67 Tool lubricator maintenance

1 Metering knob

2 Filler plug with dipstick and integrated riser

tube

3 Tool lubricator upper part with oil filling

port

4 Oil tank

5 Compressed air inlet

6 Tool oil outlet

➤ Open the canopy.

Checking the tool lubricator oil level

Check the oil level daily.

A dip stick is attached to the underside of the oil filler plug with which to measure the oil level.

The oil level should be in the upper third of the dipstick.

1.

Slowly unscrew and withdraw the oil filler plug.

2. Wipe off the dipstick with a lint-free cloth or rag and screw the plug fully in again.

3. Unscrew and withdraw the plug once more and read off the oil level on the dipstick.

Oil level at the upper third of the dip stick: OK.

Top up if the oil does not reach this level.

4. Close the canopy.

10 Maintenance

10.8 Maintenance for Optional Items

156

Operator Manual Screw Compressor

M27

No.: 9_9548 05 USE

Loading...

Loading...